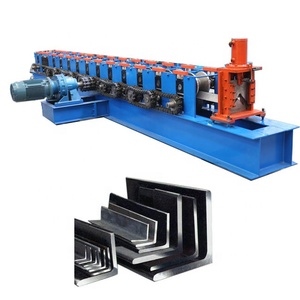

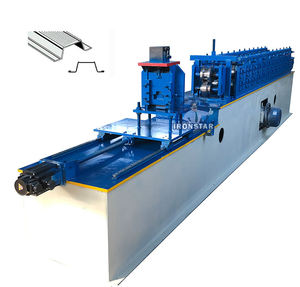

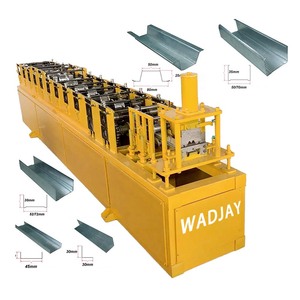

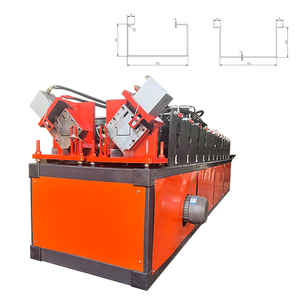

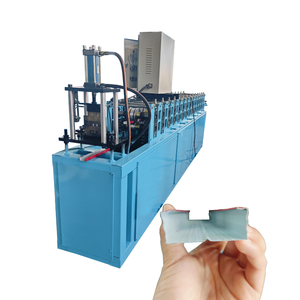

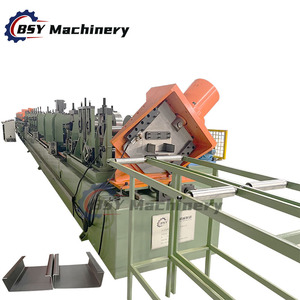

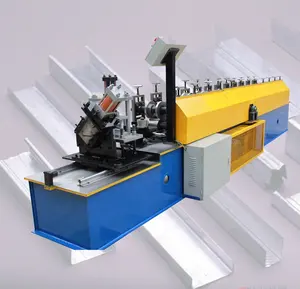

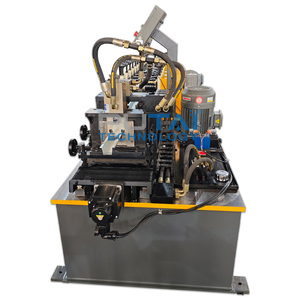

Furring Channel Roll Forming Machine China

1/27

1/27

1/25

1/25

1/20

1/20

1/11

1/11

1/19

1/19

CN

CN

1/17

1/17

CN

CN

1/9

1/9

1/11

1/11

1/12

1/12

1/35

1/35

CN

CN

1/8

1/8

1/25

1/25

About furring channel roll forming machine china

Where to Find Furring Channel Roll Forming Machine Suppliers in China?

China is the global manufacturing hub for furring channel roll forming machines, with key industrial clusters concentrated in Hebei, Henan, and Shandong provinces. These regions host vertically integrated production ecosystems that combine raw material access, precision engineering, and export logistics. Hebei and Henan alone account for over 70% of China’s light steel framing machinery output, supported by mature supply chains for cold-rolled steel, CNC components, and automation systems.

The proximity of component suppliers—such as gearbox manufacturers, servo motor providers, and roller die fabricators—enables rapid prototyping and assembly. This integration reduces lead times to 30–45 days for standard configurations and supports cost efficiency, with production expenses averaging 20–35% below Western counterparts. Buyers benefit from scalable capacity, where suppliers routinely fulfill orders ranging from single units to full container loads without significant price variation.

How to Choose Furring Channel Roll Forming Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

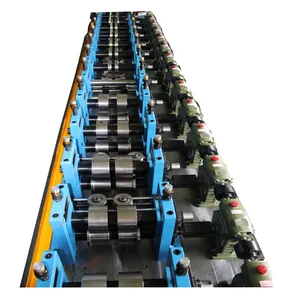

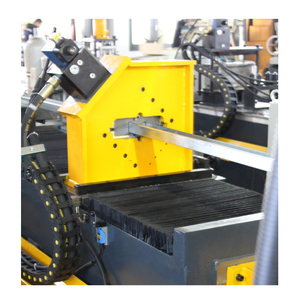

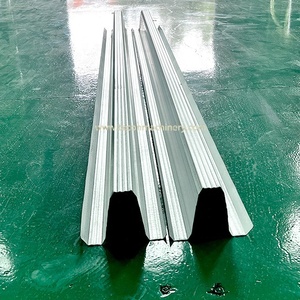

Verify adherence to international quality standards such as ISO 9001 and CE marking, particularly for electrical control panels and mechanical safety systems. Machines should support common furring profiles (C/U, Omega, Hat) and accommodate material thicknesses between 0.4–1.2mm galvanized or pre-painted steel. Confirm compatibility with standard coil widths (1220–1500mm) and yield strengths up to 550 MPa.

Production Infrastructure Assessment

Evaluate supplier capabilities through objective indicators:

- Minimum factory area exceeding 3,000m² to ensure dedicated production lines

- In-house engineering teams capable of customizing machine layouts, feeding systems, and cutting mechanisms

- Integrated CNC machining and welding stations to maintain dimensional accuracy of rollers and frames

Cross-reference on-time delivery rates (target ≥97%) and response times (≤4 hours) as proxies for operational reliability.

Procurement Risk Mitigation

Utilize secure payment methods with milestone-based releases, ideally backed by third-party inspection services upon shipment. Prioritize suppliers with documented export experience to your region, including compliance with local voltage (e.g., 380V/3P/50Hz vs. 220V/1P/60Hz) and control interface requirements. Request sample production runs or video demonstrations of test-formed channels to validate profile consistency and edge quality before full commitment.

What Are the Leading Furring Channel Roll Forming Machine Suppliers in China?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Cangzhou Zhongheng Machine Manufacture Co., Ltd. | Hebei, CN | US $410,000+ | 100% | ≤4h | 100% | $13,500–22,500 | Limited |

| Jinan Steelmama International Trade Co., Ltd. | Shandong, CN | US $400,000+ | 100% | ≤1h | 22% | $10,900–28,000 | Extensive |

| Hebei Liming Stamping Form Machine Co., Ltd. | Hebei, CN | US $730,000+ | 100% | ≤3h | <15% | $8,500–17,500 | Extensive |

| Cangzhou Zhongde Machinery Co., Ltd. | Hebei, CN | US $70,000+ | 83% | ≤1h | 33% | $6,000–18,000 | Moderate |

| Henan Wadley Cnc Machinery Co., Ltd. | Henan, CN | US $880,000+ | 97% | ≤1h | 55% | $5,700–23,000 | Extensive |

Performance Analysis

Cangzhou Zhongheng and Hebei Liming demonstrate consistent delivery performance (100% on-time), making them suitable for time-sensitive procurement. Henan Wadley stands out with the highest reorder rate (55%) and broad customization scope, indicating strong customer satisfaction and flexibility. Jinan Steelmama and Hebei Liming offer extensive configuration options—including color, logo, and profile adjustments—ideal for buyers requiring branded or region-specific adaptations. While Cangzhou Zhongde has lower on-time delivery (83%), its sub-one-hour response time reflects responsive communication. Price competitiveness is evident among newer entrants, with entry-level models starting under $6,000, though these may lack advanced automation features.

FAQs

What certifications should furring channel roll forming machine suppliers have?

Essential certifications include ISO 9001 for quality management and CE marking for electrical and mechanical safety compliance. Suppliers serving EU or North American markets should also provide documentation aligned with regional equipment directives.

What is the typical minimum order quantity (MOQ)?

The standard MOQ is one set, allowing buyers to procure individual machines for testing or small-scale operations. Bulk pricing typically applies at three or more units, depending on supplier policy.

How long does it take to receive a machine after ordering?

Lead times range from 30 to 45 days for standard models. Customized configurations may require an additional 10–20 days for design validation and component sourcing. Shipping via sea freight adds 20–40 days depending on destination port.

Can suppliers customize machine specifications?

Yes, most suppliers offer customization of roller count, motor power, control system type (PLC/HMI), cut-off mechanism, and material handling components. Engineering drawings and layout plans are typically provided within 72 hours of inquiry.

Do suppliers provide installation and training support?

Many suppliers offer remote guidance via video or manuals. On-site commissioning and operator training are available from select manufacturers, often negotiable as part of the contract or offered at an additional cost.