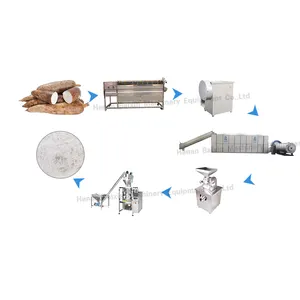

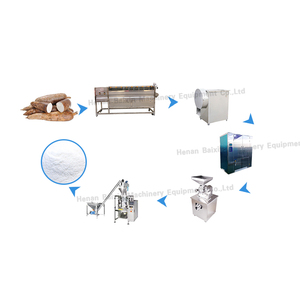

Gari Processing Machine Cassava Line Producer

CN

CN

CN

CN

CN

CN

About gari processing machine cassava line producer

Where to Find Gari Processing Machine Cassava Line Producers?

China remains the dominant hub for gari processing machine and cassava line production, with concentrated manufacturing activity in Henan and Shanghai regions. These industrial clusters offer integrated supply chains for food-grade machinery, combining engineering expertise with cost-efficient fabrication. Henan province hosts a high density of specialized equipment manufacturers, many operating within 50km of raw material suppliers and logistics centers, enabling rapid component sourcing and assembly. Shanghai-based producers leverage advanced automation and R&D infrastructure, focusing on full-scale automated lines for industrial clients.

The region’s mature ecosystem supports both small-scale and large-capacity systems, from compact 1-ton-per-hour setups to fully automated plants exceeding 50 tons/hour. Vertical integration allows suppliers to control design, machining, assembly, and testing in-house, reducing lead times to 30–45 days for standard configurations. Buyers benefit from scalable solutions, localized technical support, and 20–30% lower procurement costs compared to equivalent machinery sourced from Western or African manufacturers.

How to Choose Gari Processing Machine Cassava Line Producers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify that equipment meets food safety standards for material contact surfaces (e.g., stainless steel construction, non-toxic coatings). While explicit ISO or CE certifications are not listed in available data, prioritize suppliers offering documentation for motor efficiency, thermal control systems, and hygienic design. For export compliance, ensure machines align with destination-country electrical standards (voltage, frequency) and customs requirements for food processing equipment.

Production Capacity & Infrastructure

Assess supplier capability through key indicators:

- Facility scale supporting end-to-end line integration

- In-house engineering teams capable of customizing grating, frying, drying, and packaging modules

- Capacity to deliver complete turnkey systems, not just standalone units

Cross-reference product listings with on-time delivery performance (target ≥99%) and response time (ideally ≤3 hours) to gauge operational reliability.

Customization & Transaction Security

Confirm availability of customization for voltage, heating type, throughput capacity, and branding. Most suppliers in this segment offer logo printing, color options, and layout adjustments. Use secure payment mechanisms such as escrow services, and request detailed inspection reports before shipment. Pre-shipment testing, including dry runs and performance benchmarking, is recommended for full-line installations.

What Are the Best Gari Processing Machine Cassava Line Producers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (USD) | Key Offerings |

|---|---|---|---|---|---|---|---|---|

| Nanyang Goodway Machinery & Equipment Co., Ltd. | Henan, CN | Custom Manufacturer | US $220,000+ | 100% | ≤10h | <15% | $11,150–45,000 | Small to mid-scale gari lines, flour processing, integrated frying systems |

| Shanghai Genyond Technology Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $4,000+ | 100% | ≤3h | <15% | $10,000–100,000 | High-capacity automatic lines, starch and green bean processing adaptations |

| Henan Baixin Machinery Equipment Co., Ltd. | Henan, CN | Custom Manufacturer | US $850,000+ | 100% | ≤3h | 50% | $19,900–66,000 | Large-scale food processing lines, powder and flour systems |

| Zhengzhou Hongle Machinery Equipment Co., Ltd. | Henan, CN | Custom Manufacturer | US $270,000+ | 94% | ≤3h | <15% | $7,990–29,999 | Compact gari processing sets, peeling-drying-flour integration |

| Henan Unio Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $310,000+ | 99% | ≤2h | <15% | $99–359 | Budget grinders, small-scale flour units, high-volume pricing |

Performance Analysis

Henan Baixin stands out with a 50% reorder rate—indicating strong customer satisfaction—and offers robust mid-to-large scale systems priced between $20,000 and $66,000. Nanyang Goodway provides a broad range of complete gari lines at competitive pricing, though slower response times (≤10h) may affect urgent procurement cycles. Shanghai Genyond targets high-throughput operations with $100,000 full-automatic systems, backed by rapid response and perfect on-time delivery. Zhengzhou Hongle delivers entry-level solutions under $8,000, ideal for startups or pilot projects. Henan Unio distinguishes itself as a multispecialty supplier with ultra-low-cost components, suitable for modular builds but potentially limited in system integration support.

FAQs

What is the typical MOQ and lead time for cassava processing lines?

Minimum order quantity is typically 1 set across all suppliers. Lead times range from 20 to 45 days depending on complexity, with simple configurations shipping faster. Customized turnkey lines may require up to 60 days for fabrication and testing.

Can suppliers customize gari processing machinery?

Yes, most manufacturers offer customization for capacity, heating method (electric, diesel, gas), material finish (stainless steel grade), and branding (logo, color). Full line layouts can be adapted to facility dimensions and workflow requirements.

Do these suppliers provide installation and training?

While not explicitly stated, custom manufacturers often include remote guidance or instructional documentation. On-site support may be available at additional cost—confirm service terms during negotiation.

Are there options for low-budget buyers?

Yes. Henan Unio offers individual machines starting at $99, and Zhengzhou Hongle provides complete mini-lines near $8,000. These are suitable for small processors seeking incremental scaling rather than full automation.

How to verify machine specifications before purchase?

Request technical drawings, component lists, and video demonstrations. Conduct virtual factory audits to observe assembly processes. For critical purchases, arrange third-party inspections or order samples for performance validation prior to full deployment.