Hollow Block Machines Maker

Top sponsor listing

Top sponsor listing

1/2

1/2

1/28

1/28

1/18

1/18

0

0

1/3

1/3

1/16

1/16

1/3

1/3

1/12

1/12

1/3

1/3

1/19

1/19

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/29

1/29

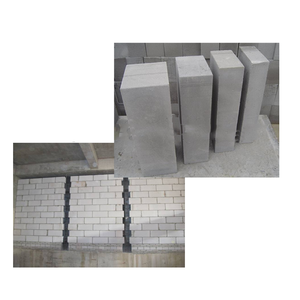

About hollow block machines maker

Where to Find Hollow Block Machines Makers?

China remains the global epicenter for hollow block machine manufacturing, with key industrial hubs in Shandong and Henan provinces driving innovation and export capacity. Shandong, particularly Qingdao and Jining, hosts vertically integrated facilities specializing in fully automatic and high-capacity production lines, supported by robust steel supply chains that reduce material costs by 15–20%. Henan’s Zhengzhou cluster accounts for over 60% of China’s brick-making machinery suppliers, leveraging centralized logistics and component sourcing to achieve faster turnaround times.

These regions offer mature ecosystems where casting, CNC machining, hydraulic system integration, and final assembly occur within tightly coordinated networks. Suppliers benefit from proximity to raw material suppliers and specialized subcontractors, enabling lead times as short as 30 days for standard models. Economies of scale allow competitive pricing across manual, semi-automatic, and fully automated systems, with customization options spanning mold configurations, power sources (electric/diesel), and integration with concrete batching plants or conveyor systems.

How to Choose Hollow Block Machines Makers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify ISO 9001 certification as a baseline for quality management systems. For international buyers, CE marking is essential for compliance with European safety standards. Request documentation on hydraulic pressure testing, vibration system durability, and electrical control panel specifications. Confirm compatibility with local grid requirements (e.g., three-phase voltage) and assess noise levels (<75 dB) for urban operation.

Production Capability Assessment

Evaluate core manufacturing infrastructure through verifiable metrics:

- Minimum factory area of 3,000m² for full production line integration

- In-house mold design and fabrication capabilities for custom block shapes

- Dedicated R&D teams supporting automation upgrades and energy efficiency improvements

Cross-reference online revenue data and on-time delivery rates (>95%) to validate operational stability and order fulfillment consistency.

Customization & After-Sales Support

Assess scope for configuration adjustments including block size (e.g., 400×200×200mm to 600×300×150mm), output capacity (800–3,000 blocks/hour), and raw material adaptability (fly ash, slag, recycled aggregates). Confirm availability of technical manuals, installation videos, and remote troubleshooting support. Prioritize suppliers offering site commissioning assistance and operator training programs.

What Are the Leading Hollow Block Machines Makers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Main Products | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Custom Manufacturer | US $390,000+ | 100% | ≤2h | 57% | Brick Making Machinery, Concrete Batching Plant, Mixers | $980–$6,580 |

| Zhengzhou Wanjun Machinery Equipment Co., Ltd. | Henan, CN | - | US $100,000+ | 100% | ≤2h | 35% | Brick Making Machinery, Crushers, Pavers | $330–$6,580 |

| Qingdao Darifeng Machinery Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $490,000+ | 95% | ≤5h | 33% | Fully Automatic Block Machines, Conveyors, Batching Systems | $10,500–$29,000 |

| Qingdao HF Machinery Technology Co., LTD | Shandong, CN | Multispecialty Supplier | US $130,000+ | 100% | ≤5h | 37% | QT Series Hydraulic Block Machines, Automation Lines | $15,500–$52,000 |

| Henan Xuefu Machinery Equipment Co., Ltd. | Henan, CN | - | US $6,000+ | 100% | ≤2h | <15% | Manual/Semi-Automatic Block Machines, Crushers | $460–$1,650 |

Performance Analysis

Shandong-based manufacturers dominate higher-end segments with advanced automation and larger-scale production systems, exemplified by Qingdao Darifeng and Qingdao HF Machinery, which offer QT-series machines capable of 2,500+ blocks per hour. These suppliers cater to commercial operations requiring consistent output and integration with concrete batching and conveyor systems. In contrast, Henan-based entities like Zhengzhou Wanjun and Henan Xuefu focus on cost-effective entry-level models ideal for small contractors or rural construction projects.

Shandong Hongfa stands out with a 57% reorder rate—the highest among peers—indicating strong customer retention likely driven by responsive service and flexible customization. While most suppliers maintain 100% on-time delivery records, response time varies: Shandong and Henan-based companies average ≤2 hours, whereas others may take up to 5 hours. Buyers seeking rapid technical feedback should prioritize suppliers with sub-2-hour response benchmarks.

FAQs

What certifications should hollow block machine suppliers have?

ISO 9001 is fundamental for quality assurance. CE certification is required for exports to Europe, ensuring compliance with health, safety, and environmental standards. Additional verification may include RoHS for electrical components and third-party inspection reports from SGS or Bureau Veritas.

What is the typical MOQ and lead time?

Minimum Order Quantity is typically 1 set for standard models. Lead time ranges from 20–30 days for manual and semi-automatic machines, extending to 45 days for fully automated lines with custom molds or auxiliary equipment integration.

Can suppliers customize machine specifications?

Yes, leading manufacturers offer extensive customization: block dimensions, mold patterns (solid, hollow, interlocking), power source (electric motor or diesel engine), vibration frequency, and hydraulic pressure settings. Some provide digital mockups and operational videos for validation prior to production.

Do suppliers support global shipping and installation?

Most established suppliers manage international logistics via FOB or CIF terms. Sea freight is standard for full-container loads. A growing number offer optional on-site installation, calibration, and worker training, especially for automated production lines exceeding $20,000 in value.

Is sample testing recommended before bulk orders?

Yes. Request test-produced blocks using your specified mix ratio (cement, sand, aggregate) to evaluate density, strength, and dimensional accuracy. Some suppliers provide machine operation videos or live video inspections during final assembly as part of pre-shipment verification.