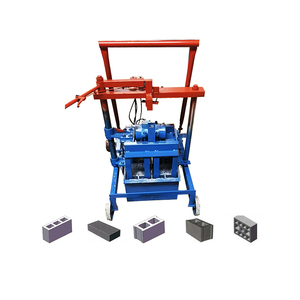

Hollow Block Making Machine Wholesaler

Top sponsor listing

Top sponsor listing

CN

CN

1/31

1/31

1/3

1/3

1/28

1/28

CN

CN

1/16

1/16

1/3

1/3

1/13

1/13

1/16

1/16

1/16

1/16

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/1

1/1

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About hollow block making machine wholesaler

Where to Source Hollow Block Making Machine Wholesalers?

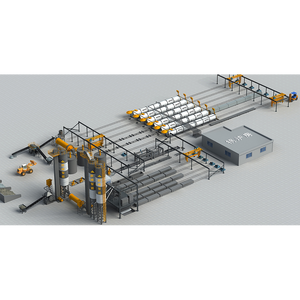

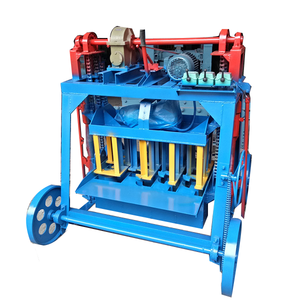

China remains the dominant hub for hollow block making machine manufacturing, with key production clusters in Shandong, Fujian, and Henan provinces. These regions host vertically integrated industrial ecosystems that support cost-efficient production and rapid scaling. Shandong and Fujian specialize in fully automatic and semi-automatic concrete machinery systems, leveraging advanced hydraulic technology and modular design principles. Henan’s suppliers focus on compact, mobile, and entry-level models suited for small-scale construction operations, often priced below $2,000.

The geographic concentration enables streamlined access to raw materials such as steel, hydraulic components, and control systems, reducing lead times by 15–25% compared to decentralized markets. Suppliers in Qingdao (Shandong) and Quanzhou (Fujian) benefit from proximity to major ports, facilitating faster export logistics. Buyers can expect standard production lead times of 20–45 days, depending on automation level and customization scope. Economies of scale allow wholesalers to offer competitive pricing, with basic models starting at $600 and high-capacity automated lines exceeding $900,000.

How to Evaluate Hollow Block Making Machine Suppliers?

Effective supplier assessment requires a structured approach focused on technical capability, operational reliability, and transactional transparency.

Technical Specifications & Customization Capacity

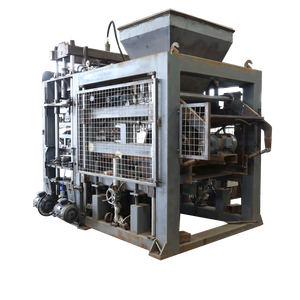

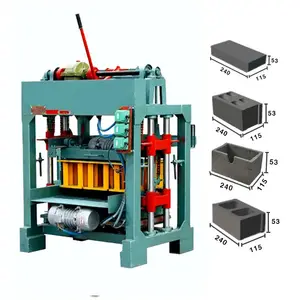

Verify compatibility with required block types (hollow, solid, interlocking), dimensions (e.g., 400×200×200 mm), and production rates (up to 2,500 blocks/hour for high-end models). Leading suppliers offer customization across mold configurations, vibration frequency, power source (electric/diesel), and conveyor integration. Confirm availability of optional features such as PLC controls, silo feeding systems, and noise-reduction engineering.

Quality Assurance and Compliance

Prioritize suppliers adhering to international quality standards. While ISO 9001 certification is not universally declared in available data, consistent on-time delivery (≥95%) and responsive communication (≤4 hours) serve as indirect indicators of process discipline. For exports to regulated markets, ensure machines comply with CE or equivalent safety directives, particularly regarding electrical systems and mechanical guarding.

Production and Operational Metrics

Assess scalability through verifiable metrics:

- Minimum factory area supporting batch production

- In-house machining capabilities (e.g., welding, CNC fabrication)

- Dedicated R&D or technical support teams

- Integration of batching plants, mixers, and curing systems

Cross-reference online revenue estimates (where available) with reorder rates—suppliers like Shandong Hongfa Scientific Industrial And Trading Co., Ltd. report over US $390,000 in online sales and a 57% reorder rate, indicating strong customer retention.

Transaction Security and After-Sales Support

Utilize secure payment mechanisms such as escrow services to mitigate risk. Request detailed documentation including machine schematics, operation manuals, and warranty terms. Confirm post-delivery support options such as remote troubleshooting, spare parts supply, and technician training. Sample testing is recommended—evaluate block density, dimensional accuracy, and cycle time before full procurement.

Top Hollow Block Making Machine Wholesalers: Performance Overview

| Company Name | Location | Verified Type | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Product Range |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Custom Manufacturer | Brick, Tile, Pipe Making Machinery, Concrete Mixers | 100% | ≤2h | US $390,000+ | 57% | 14+ models |

| Fujian Qunfeng Machinery Co., Ltd. | Fujian, CN | Custom Manufacturer | Automatic Block Machines, AAC Systems | 100% | ≤4h | Data Unavailable | Not Reported | 5 models |

| Qingdao Darifeng Machinery Co., Ltd. | Shandong, CN | Multispecialty Supplier | Hollow Block, Paver, Scaffolding Machines | 95% | ≤4h | US $490,000+ | 22% | 5 models |

| Linyi Raytone Machinery Manufacturing Co., Ltd. | Shandong, CN | Multispecialty Supplier | Automatic, Semi-Automatic Block Machines | 100% | ≤1h | US $20,000+ | 25% | 5 models |

| Henan Banrong Machinery Co., Ltd. | Henan, CN | Unverified | Mobile Brick Makers, Diesel Generators | 100% | ≤4h | US $60,000+ | <15% | 5 models |

Performance Analysis

Shandong-based suppliers demonstrate strong service consistency, with 100% on-time delivery across multiple vendors. Shandong Hongfa leads in customer loyalty (57% reorder rate) and product diversity, offering solutions from semi-auto to full-conveyor systems. Fujian Qunfeng targets premium segments with high-value AAC and large-scale concrete block lines priced above $150,000. Qingdao Darifeng stands out for technical breadth, supporting complex configurations in automation, material mixing, and mold variation.

Linyi Raytone excels in responsiveness (≤1 hour average reply time), making it ideal for time-sensitive procurement cycles. Henan Banrong offers the lowest price points (from $600), catering to budget-conscious buyers, though its sub-15% reorder rate suggests limited repeat business. Buyers seeking long-term partnerships should prioritize suppliers with proven after-sales engagement and multi-channel customization.

FAQs

What is the typical MOQ for hollow block making machines?

Most suppliers set a minimum order quantity of 1 set, regardless of model type. This allows flexibility for both individual entrepreneurs and large contractors. Bulk orders may qualify for tiered pricing and container-load optimization.

How long does production and shipping take?

Manufacturing lead time ranges from 20 to 45 days, depending on machine complexity and customization. Sea freight adds 15–35 days for international delivery, depending on destination port. Air shipment is generally not feasible due to size and weight.

Can I customize the machine for specific block sizes or shapes?

Yes, most manufacturers offer mold customization for block dimensions, surface texture (smooth, rustic, grooved), and configuration (single, double, triple cavity). Hydraulic pressure, vibration intensity, and curing cycle parameters can also be adjusted to match local material blends.

Do suppliers provide installation and training?

Support varies by vendor. Some include remote guidance or video tutorials as standard; others offer on-site technician deployment at additional cost. Clarify training scope and language support (English-speaking technicians) prior to purchase.

Are spare parts readily available?

Established suppliers maintain inventories of critical components such as molds, vibratory motors, and hydraulic cylinders. Confirm spare part lead times and pricing structure during negotiation to avoid future downtime.