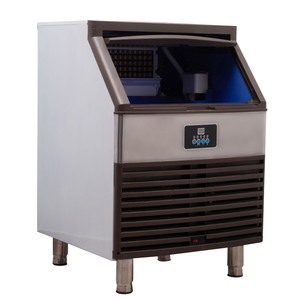

Home Under Counter Ice Maker

Top sponsor listing

Top sponsor listing

About home under counter ice maker

Where to Find Home Under Counter Ice Maker Suppliers?

China remains the dominant manufacturing hub for home under counter ice makers, with key production clusters in Guangdong and Jiangsu provinces. Guangzhou-based manufacturers leverage mature refrigeration technology ecosystems and proximity to component suppliers, enabling integrated production of compressors, evaporators, and control systems. Suzhou and Cixi in the Yangtze River Delta region specialize in compact appliance engineering, offering advanced sheet metal fabrication and injection molding capabilities that support high-volume output of slim-profile units designed for residential cabinetry integration.

These industrial zones benefit from vertically aligned supply chains—local access to stainless steel, refrigerants, and PCB controllers reduces material lead times by 20–30%. Facilities typically operate automated assembly lines capable of producing 1,500–5,000 units monthly per production line. The concentration of OEM/ODM specialists allows buyers to source both standardized models and engineered-to-order designs with cooling capacities ranging from 15kg to 150kg per 24 hours. Export infrastructure supports direct containerized shipping, with average production lead times of 30–45 days for bulk orders.

How to Choose Home Under Counter Ice Maker Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional performance indicators:

Technical & Production Capabilities

Verify that suppliers possess in-house design and tooling capacity for customized form factors compatible with standard kitchen cabinet dimensions (typically 24–33 inches wide). Prioritize manufacturers with documented experience in vapor-compression refrigeration systems and condensate management. Confirm use of food-grade materials (e.g., stainless steel interiors, BPA-free plastics) and compliance with electrical safety standards such as IEC 60335. For export markets, CE, RoHS, or ETL certification is essential for regulatory clearance.

Quality Assurance Metrics

Evaluate supplier reliability using platform-verified performance data:

- On-time delivery rate ≥95% indicates stable production scheduling

- Reorder rate >15% reflects customer retention and product satisfaction

- Average response time ≤6 hours ensures efficient communication

- Minimum factory revenue threshold (e.g., US $30,000+ annually online) suggests market validation

Cross-reference self-reported metrics with third-party transaction histories where available. Request evidence of QC protocols, including leak testing, insulation resistance checks, and continuous run tests over 72-hour cycles.

Customization and Transaction Security

Leading suppliers offer configurable options including color finishes, control panel layouts, logo branding, and bin capacity adjustments. Confirm packaging specifications (color box, labeling, manual language) are adaptable for international retail or B2B distribution. Utilize secure payment mechanisms such as escrow services to mitigate risk, especially with newer suppliers lacking long-term track records. Pre-shipment inspections by independent agencies can verify conformance to technical specifications.

What Are the Best Home Under Counter Ice Maker Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Baisheng Catering Equipment Manufacturing Co., Ltd. | Ice Machines (67) | 100% | ≤2h | <15% | $30,000+ | Color, packaging, label, capacity, output, material, size, cooling, storage, model, graphic, dimensions | Varies | Not specified |

| Suzhou Seitek Co., Ltd. | Not specified | 100% | ≤21h | Not available | Not available | Color, material, size, logo, packaging, label, graphic | 90 sets | $90–$490 |

| MASAN VIET NAM JOINT STOCK COMPANY | Robot Vacuums (29) | Not available | ≤4h | Not available | Not available | Limited data | 1–30 units | $350 |

| Guangzhou Dubang Electrical Appliances Co., Ltd. | Ice Machines (151) | 63% | ≤11h | 66% | $30,000+ | Limited data | 1–5 pieces | $500–$796 |

| Cixi Jirui Electric Appliance Co., Ltd. | Ice Crushers & Shavers (195) | 66% | ≤6h | <15% | $3,000+ | Limited data | 2–10 pieces | $150–$600 |

Performance Analysis

Guangzhou Baisheng stands out for responsiveness (≤2h) and full customization breadth, backed by consistent on-time delivery, making it suitable for buyers prioritizing communication efficiency and design flexibility. Suzhou Seitek matches perfect delivery performance but exhibits slower response cycles, which may delay project timelines. Guangzhou Dubang demonstrates strong customer retention (66% reorder rate), suggesting reliable product quality despite lower on-time fulfillment metrics. Cixi Jirui offers competitive pricing starting at $150, ideal for budget-sensitive procurements, though its 66% on-time rate warrants close logistics planning. MASAN Vietnam shows fast response times but lacks transparency in core performance indicators, increasing procurement risk.

FAQs

What certifications should home under counter ice makers comply with?

Essential certifications include CE (Europe), ETL or UL (North America), and RoHS for hazardous substance compliance. Manufacturers should also hold ISO 9001 for quality management systems. Verify documentation covers both electrical safety and refrigeration system integrity.

What is the typical MOQ for under counter ice makers?

MOQs range from 1 unit for sample testing to 90+ sets for full production runs. Some suppliers offer low MOQs (1–5 pieces) at higher per-unit costs, facilitating pilot market testing before scaling.

How long does it take to receive a custom sample?

Standard sample production takes 15–25 days, depending on design complexity. Units requiring new molds or electronic controls may require up to 40 days. Air freight adds 7–10 days for international delivery.

Can suppliers provide private labeling and packaging?

Yes, most established suppliers support OEM services including custom logos, user interface graphics, color finishes, and branded packaging. Minimum order thresholds may apply for full branding packages.

What materials are commonly used in under counter ice makers?

Exterior cabinets are typically constructed from stainless steel or powder-coated steel. Interior components use food-safe ABS plastic or stainless steel. Cooling systems rely on R134a or R600a refrigerants with copper-aluminum heat exchangers. Compressors are usually hermetic rotary or reciprocating types sourced from certified vendors.