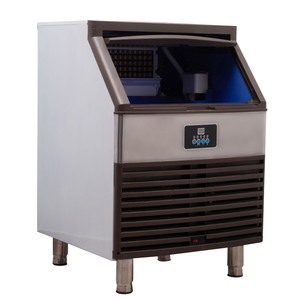

Under The Counter Ice Maker Machine

CN

CN

About under the counter ice maker machine

Where to Find Under the Counter Ice Maker Machine Suppliers?

China remains the dominant manufacturing hub for under the counter ice maker machines, with key production clusters concentrated in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, stainless steel stamping, refrigeration system assembly, and final product testing. Guangzhou and Suzhou serve as primary export centers, offering proximity to major ports like Nansha and Shanghai, which reduces logistics lead times by 7–10 days compared to inland facilities.

The industrial ecosystems support high-volume output with flexible customization, enabling rapid scaling from prototype to mass production within 30–45 days. Facilities typically integrate CNC machining, automated welding, and hydrostatic pressure testing lines, ensuring consistent quality across batches. Buyers benefit from localized access to core components such as hermetic compressors, evaporator molds, and condenser coils, reducing material procurement cycles and lowering overall production costs by 20–25% versus non-specialized manufacturers.

How to Choose Under the Counter Ice Maker Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify adherence to international safety and performance standards, including CE (EN 60335-2-89), RoHS, and UL/cUL for North American markets. Prioritize suppliers providing third-party test reports for electrical insulation, refrigerant leakage, and energy efficiency. ISO 9001 certification should be considered a baseline requirement for quality management systems.

Production Capability Assessment

Evaluate infrastructure and capacity indicators:

- Minimum factory area of 3,000m² for dedicated refrigeration equipment lines

- In-house engineering teams capable of mold design, thermal load calculation, and airflow simulation

- On-site testing chambers for validating 24-hour ice yield under variable ambient temperatures (up to 43°C)

- Integration of front-ventilation designs to support undercounter installation in confined spaces

Cross-reference claimed production volumes with verifiable on-time delivery rates (target ≥96%) and reorder metrics.

Procurement & Transaction Safeguards

Utilize secure payment mechanisms such as trade assurance or escrow services until post-delivery inspection is completed. Request sample units to validate build quality, noise levels (typically ≤45 dB), and actual ice production against rated capacity. Confirm packaging specifications include double-walled cartons with foam reinforcement to prevent transit damage.

What Are the Best Under the Counter Ice Maker Machine Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Range | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| MASAN VIET NAM JOINT STOCK COMPANY | Vietnam | - | Not specified | ≤5h | Not specified | 30 units | $350 | Limited |

| Suzhou Seitek Co., Ltd. | Jiangsu, CN | Custom Manufacturer | 100% | ≤23h | Not specified | 90–198 sets | $310–$490 | Color, size, logo, packaging, label, graphic |

| Jiangmen Pro-Taylor Refrigeration Co., Ltd. | Guangdong, CN | Custom Manufacturer | 96% | ≤3h | 21% | 1–10 units | $269–$1,466 | Capacity, dual water inlet, sensor, color, logo, material, size, economy models |

| Guangzhou Anhe Catering Equipment Co., Ltd. | Guangdong, CN | Multispecialty Supplier | 100% | ≤4h | 31% | 5 pieces | $515–$945 | Ice type, cooling method, compressor specs, storage capacity, controller, phase, voltage, weight, dimensions |

| Guangzhou LVNI Hotel Supplies Co., Ltd. | Guangdong, CN | Custom Manufacturer | 100% | ≤4h | 33% | 1 piece | $320–$1,318 | Color, size, logo, packaging, label, graphic |

Performance Analysis

Guangdong-based suppliers dominate responsiveness and flexibility, with three out of five achieving sub-4-hour average response times and MOQs as low as one unit—ideal for boutique hospitality projects or pilot deployments. Jiangmen Pro-Taylor and Guangzhou LVNI offer strong customization depth, particularly in water inlet configuration and control systems, catering to diverse regional plumbing codes. Suzhou Seitek provides competitive pricing for bulk orders but enforces high minimums (90+ sets), indicating focus on large-scale commercial contracts. Guangzhou Anhe stands out with comprehensive technical configurability, including options for air-cooled vs. water-cooled condensers and full/half cube molding, supported by a 31% reorder rate signaling customer satisfaction.

FAQs

How to verify under the counter ice maker machine supplier reliability?

Cross-check certifications (CE, ISO) through official registries. Request facility audit reports or video walkthroughs confirming in-house production capabilities. Analyze transaction history focusing on dispute resolution speed and after-sales service responsiveness.

What is the typical lead time for production and shipping?

Standard order fulfillment ranges from 25–35 days for manufacturing, plus 15–25 days for sea freight to North America or Europe. Air shipping reduces delivery to 5–10 days but increases transport costs by 300–400%.

Can suppliers customize ice shape and size?

Yes, most custom manufacturers support full cube, half cube, crescent, and nugget ice configurations via mold modification. Minimum order quantities may apply depending on tooling complexity.

Do suppliers offer free samples?

Sample policies vary; some waive fees for confirmed bulk orders (e.g., 10+ units). For standalone samples, expect partial cost recovery charges ranging from 50–70% of unit price, refundable upon order placement.

What are common customization parameters?

Key configurable features include ice production capacity (50–150kg/24h), voltage (110V/220V), phase (single/three-phase), cooling method (air/water-cooled), cabinet finish (stainless steel grade), digital controls, and noise reduction packages. OEM branding is widely available for logos and user interfaces.