Ice Cube Machine Maker

CN

CN

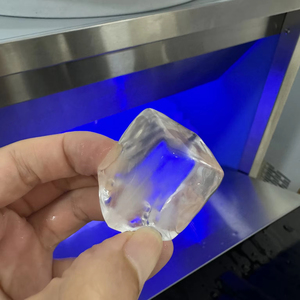

About ice cube machine maker

Where to Find Ice Cube Machine Maker Suppliers?

China remains the dominant hub for industrial ice cube machine manufacturing, with key supplier clusters concentrated in Anhui, Guangdong, Zhejiang, and Henan provinces. These regions host vertically integrated production ecosystems that combine sheet metal fabrication, refrigeration system assembly, and automated control integration under one roof. Anhui and Guangdong lead in commercial-scale cube ice makers, leveraging proximity to compressor suppliers and port logistics for export efficiency. Ningbo and Shanghai-based manufacturers specialize in high-capacity systems (1–10 tons/24h), integrating advanced cooling technologies such as air- or water-cooled condensers with Danfoss or Bitzer compressors.

The regional supply chains enable cost optimization through localized sourcing of stainless steel, evaporator molds, and electrical components, reducing material procurement cycles by 25–30%. Most facilities operate full production lines—from laser cutting and bending to final assembly—supporting MOQs as low as 1 set for standard models. Buyers benefit from scalable output capacity, with lead times averaging 20–35 days for containerized orders. The ecosystem also supports rapid prototyping for customized configurations, including dual-purpose spray-flake systems or solar-compatible units with Siemens PLC controls.

How to Choose Ice Cube Machine Maker Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional criteria:

Technical Compliance & Quality Assurance

Verify adherence to international standards such as CE, RoHS, and ISO 9001. For markets requiring regulatory approval (EU, North America), confirm compliance documentation for refrigerant types (e.g., R404A, R134a) and electrical safety (IP ratings, grounding). Request test reports on cooling cycle stability, energy consumption per kg of ice, and water usage efficiency.

Production Capability Assessment

Evaluate core manufacturing competencies:

- Minimum factory area of 3,000m² indicating dedicated production zones

- In-house engineering teams supporting customization (e.g., language interface, plug type, phase voltage)

- On-site testing facilities validating 24-hour output consistency and self-cleaning functionality

Cross-reference online revenue indicators and on-time delivery rates (>95%) to assess operational reliability.

Customization and After-Sales Support

Confirm scope of configurable parameters: ice cube size (standard: 22×22×22mm to 38×38×38mm), daily capacity (50kg to 10,000kg), ambient operating temperature range (up to 43°C), and packaging specifications. Prioritize suppliers offering multilingual operation panels, remote diagnostics, and modular design for simplified maintenance.

Transaction Risk Mitigation

Utilize secure payment frameworks with milestone releases tied to production progress. Require third-party pre-shipment inspections (e.g., SGS, BV) for orders exceeding 5 units. Analyze reorder rates (>20%) and response times (≤2 hours) as proxies for customer satisfaction and service responsiveness.

What Are the Best Ice Cube Machine Maker Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Min. Order | Output Range |

|---|---|---|---|---|---|---|---|---|

| Anhui Liangzhi Energy Saving Technology Co., Ltd. | Anhui, CN | US $310,000+ | 98% | ≤1h | 21% | Yes | 1 set | 500–2,400kg/24h |

| Guangzhou Naixer Refrigeration Equipment Co., Ltd. | Guangdong, CN | US $160,000+ | 94% | ≤2h | 21% | Yes | 1–5 sets | 150–2,970kg/24h |

| NINGBO KAISON ELECTRIC APPLIANCE CO.,LTD | Zhejiang, CN | US $110,000+ | 100% | ≤1h | 15% | Yes | 1–3 pieces | 100–2,560kg/24h |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | US $440,000+ | 98% | ≤2h | 34% | Yes | 1 set | 280–4,400kg/24h |

| Shanghai Icema Refrigeration Technology Co., Ltd. | Shanghai, CN | US $1,200,000+ | 95% | ≤2h | 24% | Yes | 1–2 sets | 1,000–10,000kg/24h |

Performance Analysis

Shanghai Icema leads in high-capacity industrial systems, offering fully automatic packaging lines and containerized designs suitable for large beverage or seafood processing plants. With the highest reported online revenue, it demonstrates strong export scalability despite a slightly lower on-time delivery rate. Zhengzhou Yize stands out with a 34% reorder rate—the highest among peers—indicating strong post-sale performance and customer retention. NINGBO KAISON achieves perfect on-time delivery (100%), suggesting disciplined production planning, though its lower reorder rate may reflect less comprehensive after-sales engagement. Anhui Liangzhi and Guangzhou Naixer offer competitive entry-level pricing with MOQs starting at 1 set, making them viable for small-to-mid commercial buyers. All five suppliers support customization in material (stainless steel grade 304/316), color, logo branding, and control panel language, enabling region-specific compliance and branding.

FAQs

How to verify ice cube machine maker reliability?

Cross-check certifications (CE, ISO 9001) with official registries. Request factory audit reports or video walkthroughs confirming in-house production capabilities. Analyze historical order data, focusing on consistent on-time delivery (>95%) and active transaction volume.

What is the typical lead time for ice cube machines?

Standard orders require 20–30 days for production and packaging. Larger systems (5+ tons) or custom configurations may extend to 35–45 days. Air freight allows delivery within 5–7 days; sea freight takes 15–30 days depending on destination port.

Can suppliers accommodate OEM/ODM requests?

Yes, all listed suppliers support OEM labeling, graphic customization, and technical modifications such as plug type (EU/US/AU), voltage (single/three-phase), and refrigeration method. Minimum branding MOQ typically starts at 5 units.

Do ice cube machine makers provide after-sales technical support?

Most offer remote troubleshooting via multilingual support teams. High-output systems often include PLC-based diagnostics. Some suppliers provide field technician deployment or training sessions upon request, particularly for turnkey installations.

What are common customization parameters?

Key configurable features include ice cube dimensions, daily output capacity, cooling method (air/water), compressor brand (e.g., Danfoss, Emerson), control interface language, cabinet material thickness, and storage bin integration. Custom packaging and eco-labeling are also widely available.