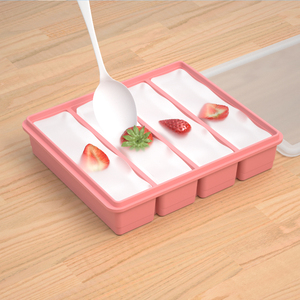

Ice Cube Maker Trays

About ice cube maker trays

Where to Find Ice Cube Maker Tray Suppliers?

China remains the dominant hub for ice cube maker tray manufacturing, with key production clusters in Guangdong, Zhejiang, and Fujian provinces. These regions host vertically integrated supply chains specializing in food-grade silicone and BPA-free plastic molding, enabling high-volume output at competitive costs. Shenzhen and Guangzhou serve as primary centers for silicone-based kitchenware, leveraging proximity to polymer suppliers and export ports like Shekou and Yantian. Hangzhou and Huizhou contribute strong secondary capacity, particularly in injection-molded plastics and multi-cavity tray designs.

The industrial ecosystem supports rapid prototyping and scalable production, with many facilities operating automated molding lines capable of producing 50,000–200,000 units monthly. Buyers benefit from localized access to raw materials, packaging suppliers, and logistics networks, reducing lead times to 15–30 days for standard orders. Economies of scale allow cost advantages of 20–35% compared to non-Asian manufacturers, especially for bulk quantities exceeding 10,000 pieces. The concentration of OEM/ODM-capable factories also enables flexible customization in shape, grid count, color, and branding.

How to Choose Ice Cube Maker Tray Suppliers?

Procurement decisions should be guided by systematic evaluation of supplier capabilities and compliance:

Material & Safety Compliance

Verify use of food-grade silicone (FDA 21 CFR 177.2600 compliant) or BPA-free plastics meeting EU Regulation (EC) No 1935/2004 and FDA standards. Request test reports for LFGB, RoHS, or REACH compliance where applicable. For export markets, ensure molds are designed to prevent leaching and meet dishwasher-safe durability benchmarks.

Production & Customization Capacity

Assess technical infrastructure through the following indicators:

- Minimum order quantity (MOQ) flexibility: Competitive MOQs range from 1–50 pieces for sample batches to 100+ for full production runs

- In-house mold-making capability for custom shapes (e.g., spheres, geometric cubes, novelty designs)

- Digital design support for logo, label, and packaging customization

Cross-reference product listings with on-time delivery rates (>90% recommended) and response times (≤5 hours preferred).

Transaction Reliability & Quality Control

Prioritize suppliers with documented quality management systems and verifiable performance metrics. Analyze reorder rates as an indicator of customer satisfaction—rates below 15% may indicate inconsistent quality or service. Use secure payment mechanisms and request pre-shipment inspections for initial orders. Sample testing is critical to evaluate ease of release, structural integrity after freeze-thaw cycles, and dimensional accuracy.

What Are the Best Ice Cube Maker Tray Suppliers?

| Company Name | Location | Main Materials | Customization Options | MOQ Range | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Zhida Xintai Technology Co., Ltd. | Guangdong, CN | Silicone, Plastic | Color, size, design, logo, packaging | 32 sets – 50 pieces | 96% | ≤5h | US $170,000+ | <15% |

| Huizhou Guangshunlai Industrial Co., Ltd. | Guangdong, CN | Silicone (food-grade) | Limited customization | 3–100 pieces | 92% | ≤3h | US $9,000+ | <15% |

| Guangzhou Raybin Homewares Co., Ltd. | Guangdong, CN | Plastic, Silicone | Color, material, logo, packaging | 100 pieces | 92% | ≤2h | US $590,000+ | 27% |

| Hangzhou Top Leader Technology Co., Ltd. | Zhejiang, CN | Silicone (flexible, 3D press-type) | Design-focused, creative molds | 1–4 pieces | 100% | ≤3h | US $70,000+ | <15% |

| Yongkang Purplewind Industry & Trade Co., Ltd. | Zhejiang, CN | Silicone (novelty shapes) | Custom designs (crystal, honeycomb, shark fin) | 3–100 pieces | 100% | ≤20h | US $2,000+ | - |

Performance Analysis

Guangzhou Raybin leads in transaction volume and offers robust customization, though its 27% reorder rate suggests room for improvement in long-term client retention. Hangzhou Top Leader and Shenzhen Zhida Xintai achieve perfect on-time delivery records, indicating strong operational control. Hangzhou stands out for ultra-low MOQs (as low as 1 piece), ideal for niche or trial orders. Yongkang Purplewind specializes in novelty designs but has limited revenue transparency and slower response times. Suppliers in Guangdong dominate overall capacity and responsiveness, with average reply times under 3 hours—critical for agile sourcing cycles.

FAQs

How to verify ice cube tray material safety?

Request compliance documentation for FDA, LFGB, or EU food contact regulations. Conduct third-party lab testing for plasticizers, heavy metals, and thermal stability if sourcing large volumes. Confirm that silicone products are platinum-cured rather than peroxide-cured for higher purity.

What is the typical lead time for bulk orders?

Standard production lead time ranges from 15 to 25 days after sample approval. Orders requiring custom molds may add 7–14 days for tooling. Air freight adds 5–10 days; sea freight takes 20–35 days depending on destination.

Can suppliers provide private labeling and custom packaging?

Yes, most established suppliers offer full OEM/ODM services including custom colors, logos, stickers, and retail-ready packaging. Minimum requirements typically start at 1,000–5,000 units depending on complexity.

Do ice cube tray suppliers offer free samples?

Sample policies vary. Some suppliers offer paid samples ($0.20–$12.50/unit) refundable against future orders. Free samples are rare but possible for high-potential buyers or standard in-stock items.

How to assess mold durability and product lifespan?

Evaluate tensile strength (≥6 MPa for silicone), elongation at break (>300%), and resistance to 50+ freeze-thaw cycles. Request physical samples to test flexibility, ease of ice release, and edge wear after repeated use.