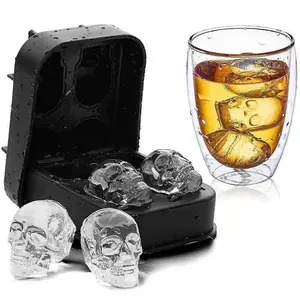

Ice Cube Mold Maker

1/16

1/16

1/3

1/3

1/3

1/3

0

0

1/35

1/35

1/3

1/3

1/3

1/3

1/2

1/2

1/29

1/29

1/3

1/3

1/22

1/22

1/3

1/3

1/1

1/1

1/4

1/4

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/41

1/41

About ice cube mold maker

Where to Find Ice Cube Mold Maker Suppliers?

China remains the global epicenter for ice cube mold manufacturing, with concentrated production clusters in Guangdong, Fujian, and Zhejiang provinces. These regions host vertically integrated silicone processing facilities that support rapid prototyping and scalable output. Shenzhen and Dongguan in Guangdong province specialize in food-grade silicone products, leveraging proximity to raw material suppliers and export ports to reduce logistics lead times by 15–20%. Xiamen-based manufacturers benefit from established supply chains for BPA-free polymers and FDA-compliant additives, enabling faster compliance validation for North American and EU markets.

The industrial ecosystem supports high flexibility in production volume and design complexity. Facilities typically integrate injection molding, curing ovens, and quality inspection lines under one roof, allowing batch turnaround within 15–20 days for standard orders. Buyers gain access to mature networks where tooling workshops, packaging suppliers, and logistics providers operate within close geographic proximity—reducing coordination overhead and minimizing delays. Average monthly production capacity among mid-tier suppliers ranges from 100,000 to 500,000 units, with scalability for OEM/ODM contracts requiring custom molds or multi-color configurations.

How to Choose Ice Cube Mold Maker Suppliers?

Prioritize these verification criteria when evaluating potential partners:

Material & Safety Compliance

Confirm use of food-grade silicone (FDA 21 CFR §177.2600) or BPA-free thermoplastics. Require documentation for RoHS, LFGB, or REACH compliance depending on target market regulations. Insist on third-party test reports for migration and heavy metal content, particularly for molds intended for children’s products or beverage use.

Production Capability Assessment

Evaluate technical infrastructure based on the following benchmarks:

- Minimum factory area of 2,000m² for dedicated molding and packaging lines

- In-house mold design and CNC tooling capabilities for customization

- Monthly output capacity exceeding 100,000 units for inventory stability

Cross-reference declared capabilities with verified on-time delivery rates (target ≥95%) and response time metrics to assess operational reliability.

Customization & Transaction Security

Verify support for OEM/ODM services including logo embossing, color matching (Pantone standards), and retail-ready packaging. Demand clear IP protection agreements before sharing proprietary designs. Utilize secure payment mechanisms such as escrow services, and prioritize suppliers participating in verified transaction programs. Pre-shipment inspections should include dimensional accuracy checks and demolding performance tests under freezing conditions.

What Are the Best Ice Cube Mold Maker Suppliers?

| Company Name | Location | Online Revenue | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Range | Customization |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Zhida Xintai Technology Co., Ltd. | Guangdong, CN | US $180,000+ | Silicone Molds, Food Storage | 96% | ≤4h | <15% | 32–100 pcs | Color, size, logo, packaging |

| Spec-Tech (Xiamen) Co., Ltd. | Fujian, CN | US $40,000+ | Ice Cream Tools, Cake Molds | 100% | ≤1h | 25% | 200–500 pcs | 3D shapes, BPA-free materials |

| Yongkang E Spring Silicone Products Factory | Zhejiang, CN | US $90,000+ | Silicone Molds, Pet Bowls | 95% | ≤3h | 15% | 5–10 pcs | Round/square cavity designs |

| Ningbo Xinggui Rubber Plastic Co., Ltd. | Zhejiang, CN | US $40,000+ | Ice Cream Molds, Pastry Tools | 98% | ≤8h | 16% | 5–10 pcs | Mini/multi-cavity layouts |

| Dongguan GMI Electronic Co., Ltd. | Guangdong, CN | US $140,000+ | BPA-Free Trays, Freezer Containers | 94% | ≤4h | <15% | 50–500 pcs | Logo, weight, label, graphic |

Performance Analysis

Spec-Tech (Xiamen) leads in responsiveness with a 100% on-time delivery rate and sub-1-hour average reply time, indicating robust order management systems. Shenzhen Zhida Xintai and Dongguan GMI offer strong customization depth across color, size, and branding elements, suitable for private-label brands targeting specialty retail. Yongkang E Spring and Ningbo Xinggui provide lower MOQs (as low as 5 pieces), making them ideal for startups or niche product testing. However, their higher reorder rates suggest customer acquisition challenges despite competitive pricing. Suppliers in Guangdong report higher online revenue volumes, reflecting greater export experience and digital sales maturity.

FAQs

How to verify ice cube mold material safety?

Request full material disclosure and independent lab certification for FDA, LFGB, or RoHS compliance. Conduct extractable and leachable testing if used for infant or medical applications. Visual inspection should confirm uniform texture without bubbling or discoloration after freeze-thaw cycles.

What is the typical lead time for custom molds?

Custom mold development requires 7–14 days for design approval and tooling fabrication. Sample production follows within 5–7 days. Full production batches ship within 15–20 days post-approval. Rush services may reduce timelines by 30% with expedited fees.

Can suppliers accommodate small orders?

Yes, several suppliers accept MOQs as low as 5–10 pieces for standard designs. However, unit costs decrease significantly at 100+ units. For customized items, MOQs range from 200–500 pieces depending on complexity and tooling requirements.

Do manufacturers provide free samples?

Sample policies vary. Many suppliers offer paid samples (priced at 1.5x–2x unit cost) applicable toward future orders. Free samples are typically reserved for high-potential buyers with projected annual volumes exceeding 10,000 units.

How to initiate OEM/ODM projects?

Submit detailed specifications including desired dimensions, cavity count, shape geometry, material type, and branding elements. Reputable suppliers will provide 2D/3D design files within 72 hours and produce functional prototypes within two weeks for validation.