Ice Machine That Makes Clear Ice

CN

CN

About ice machine that makes clear ice

Where to Find Suppliers for Ice Machines That Make Clear Ice?

China remains the dominant manufacturing hub for commercial and industrial ice machines that produce clear ice, with key production clusters in Guangdong, Jiangsu, and Shandong provinces. These regions host vertically integrated supply chains encompassing refrigeration engineering, precision molding, and stainless steel fabrication—critical for producing high-clarity ice through controlled freezing cycles. Guangzhou and Nantong-based manufacturers leverage proximity to port infrastructure and component suppliers, reducing logistics lead times by 15–20% compared to non-specialized regions.

The concentration of technical expertise enables scalable production across capacity tiers—from compact 40kg/day units for bars and restaurants to industrial systems generating up to 30 tons daily. Suppliers benefit from localized access to compressors, evaporators, and food-grade stainless steel, ensuring consistent material quality and cost efficiency. Buyers gain flexibility in sourcing both standardized models and engineered solutions, supported by mature ecosystems where R&D, assembly, and testing occur within consolidated facilities.

How to Choose Suppliers for Clear Ice Machines?

Effective supplier evaluation requires a structured assessment of technical capability, operational reliability, and transactional transparency:

Technical & Quality Compliance

Verify adherence to international standards such as CE and ISO 9001, particularly for electrical safety, refrigerant handling (e.g., R404A, R134a), and hygienic design. Clear ice production demands precise temperature control and water circulation systems; request documentation on condenser types (air/water-cooled), compressor brands (e.g., Bitzer, Embraco), and filtration integration. For foodservice applications, ensure compliance with NSF or equivalent hygiene certifications.

Production Capacity Verification

Assess infrastructure indicators to confirm scalability:

- Minimum factory area exceeding 3,000m² for stable batch output

- Dedicated R&D or engineering teams focused on thermal efficiency optimization

- In-house assembly lines with sealed chamber construction and automated defrost cycles

Cross-reference online revenue metrics and order fulfillment rates (target ≥95%) to validate operational consistency.

Procurement & Transaction Safeguards

Utilize secure payment mechanisms such as escrow services until post-arrival performance verification. Prioritize suppliers offering sample testing—ideally with video demonstrations of ice clarity, cycle duration, and harvest mechanism. Confirm minimum order quantities (MOQs), which typically range from 1 set for standard models to container-based batches for large-scale deployments.

What Are the Leading Suppliers of Ice Machines That Make Clear Ice?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response Time | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Nantong Wuding Technology Co., Ltd. | Ice Machines (380) | 97% | 17% | ≤3h | $60,000+ | $180–$957 | 1 set |

| Jinan Robin Machinery Co., Ltd. | Ice Machines (721) | 100% | 22% | ≤2h | $100,000+ | $5,000–$419,000 | 1 set |

| Guangzhou Koller Refrigeration Equipment Co., Ltd. | Ice Machines (262) | 100% | <15% | ≤7h | Not disclosed | $5,900–$19,980 | 1 set |

| Shanghai Snowdream Refrigeration Equipment Co., Ltd. | Ice Machines (776) | 93% | 20% | ≤4h | $700,000+ | $200–$800 | 1–5 pieces |

| Guangzhou Icesource Co., Ltd. | Customization-focused ice systems | 95% | 37% | ≤1h | $400,000+ | $22,900–$100,000 | 1 set |

Performance Analysis

Shanghai Snowdream leads in product volume and affordability, offering entry-level clear ice machines starting at $200 with strong online sales performance. Jinan Robin and Guangzhou Koller demonstrate high delivery reliability (100%), catering to mid-to-large scale operations requiring transparent cube or block ice. Nantong Wuding provides cost-effective options under $200, suitable for small commercial setups. Guangzhou Icesource stands out with the highest reorder rate (37%), indicating strong customer satisfaction, and offers extensive customization—including ice shape (tube, ball, crescent), capacity (5–30 ton/day), and branding options—making it ideal for specialized hospitality or retail applications.

FAQs

How is clear ice produced in these machines?

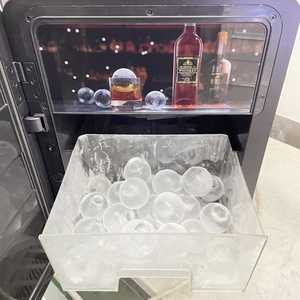

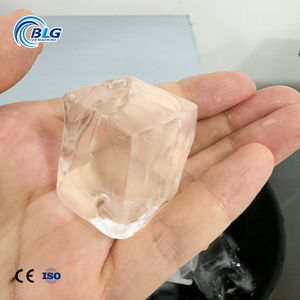

Clear ice is formed through directional freezing technology, where water flows over a chilled evaporator plate while impurities and air are flushed away. This slow, controlled process results in dense, transparent ice cubes, spheres, or blocks with minimal cloudiness—ideal for premium beverage service.

What is the typical lead time for orders?

Standard models generally ship within 15–25 days after order confirmation. Custom-engineered systems may require 30–45 days depending on complexity. Air freight allows delivery in 7–10 days globally; sea freight takes 25–40 days but is more economical for full-container loads.

Do suppliers offer OEM/ODM services?

Yes, many manufacturers support OEM branding, including custom logos, color schemes, packaging, and user interface labels. ODM capabilities extend to modifying ice dimensions, production capacity, voltage specifications (110V/220V), and integrating smart controls or energy-saving features.

Can I request a sample before bulk ordering?

Most suppliers allow sample purchases, often at 1.5x the unit price, which may be credited toward future bulk orders. Video validation of ice clarity, machine operation, and noise levels is commonly provided when physical sampling is not feasible.

What are common customization options?

Buyers can specify ice type (cube, tube, sphere, block), daily output (40kg to 30 tons), refrigerant type, power supply, cabinet material (stainless steel grade 304/316), water inlet configuration, and control panel language. Some suppliers also integrate IoT monitoring for remote diagnostics and maintenance alerts.