Inductive Proximity Sensor

Top sponsor listing

Top sponsor listing

1/3

1/3

1/58

1/58

1/3

1/3

1/3

1/3

1/17

1/17

CN

CN

1/1

1/1

0

0

0

0

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

1/26

1/26

1/3

1/3

About inductive proximity sensor

Where to Find Inductive Proximity Sensor Suppliers?

China remains the central hub for inductive proximity sensor manufacturing, with key production clusters concentrated in Shanghai, Shenzhen, and Wenzhou. These regions host vertically integrated facilities that combine R&D, precision machining, and automated assembly lines, enabling competitive pricing and scalable output. Shanghai-based suppliers leverage mature industrial ecosystems and proximity to international ports, facilitating efficient export logistics. Shenzhen’s electronics manufacturing infrastructure supports high-volume production with rapid prototyping capabilities, while Wenzhou specializes in cost-effective electromechanical components with strong supply chain integration.

Suppliers in these zones benefit from localized access to raw materials such as copper, stainless steel, and engineering plastics, reducing material lead times by 20–30%. Average monthly production capacity among verified manufacturers exceeds 50,000 units, with some facilities achieving up to 200,000 units through semi-automated surface-mount and potting processes. This concentration enables buyers to source both standard models (M8, M12, M18) and specialized configurations—including flush/non-flush types, AC/DC variants, and extended temperature range sensors—within consolidated supply chains.

How to Choose Inductive Proximity Sensor Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international standards such as CE, RoHS, and ISO 9001. While not all suppliers explicitly list certifications in public profiles, consistent compliance is indicated by product-level testing documentation for dielectric strength, IP ratings (typically IP67), and EMC performance. Buyers targeting European or North American markets should require proof of conformity for electromagnetic compatibility and environmental directives.

Production & Customization Capability

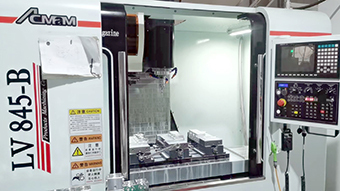

Assess the following indicators of manufacturing maturity:

- In-house tooling and molding capacity for housing and coil formers

- Ability to customize sensor parameters: detection range (2–40mm), output type (PNP/NPN, NO/NC), voltage (10–30V DC), cable length, and connector type

- Support for OEM branding, including laser marking, packaging labels, and custom color coding

- Design flexibility for non-standard dimensions, temperature ranges (-25°C to +70°C standard, extended upon request), and material resistance (stainless steel AISI 303/316)

Cross-reference customization claims with actual product listings showing variations in shape, size, and labeling. Suppliers with dedicated R&D teams can typically provide technical drawings and validation reports within 48 hours.

Performance & Transaction Reliability

Prioritize suppliers demonstrating measurable operational efficiency:

- On-time delivery rate ≥96% (top performers achieve 100%)

- Average response time ≤2 hours, with sub-1-hour responsiveness indicating high service priority

- Reorder rates above 15% suggest customer satisfaction and product reliability

- Minimum order quantities (MOQ) ranging from 1 to 20 pieces accommodate sample testing and low-volume procurement

Use platform-verified revenue data (e.g., US $50,000+ annual online turnover) as a proxy for market presence and order fulfillment consistency.

What Are the Best Inductive Proximity Sensor Suppliers?

| Company Name | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|---|

| Shanghai Lanbao Sensing Technology Co., Ltd. | Custom Manufacturer | Proximity Sensors, Optical Sensors, Ultrasonic Sensors | US $640,000+ | 99% | ≤2h | 16% | Color, shape, output type, cable length, sensor size, logo, temperature range | 1 piece |

| Beijing Shuntu Technology Co., Ltd. | Distributor/Reseller | Push Button Switches, Relays, Proximity Sensors | US $100,000+ | 96% | ≤3h | 17% | Limited (based on brand availability) | 5 pieces |

| Shenzhen Perfect Precision Product Co., Ltd. | Custom Manufacturer | Inductive Proximity Sensors, Photoelectric Sensors | US $50,000+ | 96% | ≤1h | 24% | Digital outputs, material specs, waterproof models, graphic labels, relay integration | 1 piece |

| Wenzhou Chen Intelligent Technology Co., Ltd. | Custom Manufacturer | Solenoids, Contactors, Proximity Sensors | US $30,000+ | 100% | ≤1h | <15% | Output configuration, terminal type, model-specific adjustments | 10 pieces |

Performance Analysis

Shanghai Lanbao stands out for high-volume reliability and broad customization, supported by substantial online revenue and consistent 99% on-time delivery. Its status as a custom manufacturer enables full design control, making it suitable for OEM integrations. Shenzhen Perfect Precision demonstrates exceptional responsiveness (≤1h) and the highest reorder rate (24%), suggesting strong post-sale satisfaction despite lower revenue volume. Wenzhou Chen achieves perfect on-time performance and rapid communication, ideal for time-sensitive orders, though its higher MOQ (10 pieces) may limit flexibility for testing. Beijing Shuntu serves as a multi-brand distributor with moderate customization, best suited for buyers seeking established sensor models rather than bespoke development.

FAQs

How to verify inductive proximity sensor supplier reliability?

Evaluate on-time delivery history, response speed, and reorder rates as behavioral proxies for service quality. Request product test reports for insulation resistance, operating voltage tolerance, and switching cycle endurance (typically rated at 1 million cycles). For critical applications, conduct remote factory audits via video tour to confirm production lines and QC procedures.

What is the typical lead time for samples and bulk orders?

Sample production takes 5–10 days, with global air shipping adding 7–10 days. Standard bulk order lead times range from 15 to 30 days depending on customization level and order size. Expedited production (10–15 days) is available from manufacturers with in-house coil winding and encapsulation capabilities.

Can suppliers provide customized technical specifications?

Yes, custom manufacturers support modifications to detection distance, hysteresis, output signal type, housing diameter, and cable exit orientation. Provide detailed requirements including load current, ambient temperature, target material (ferrous/non-ferrous), and mounting constraints for accurate quoting.

Are free samples available?

Some suppliers offer paid samples with fee reimbursement upon order placement. Units priced below $5 are often available at cost for evaluation. Free samples are rare but possible for high-potential buyers committing to future volume orders.

What are common packaging and labeling options?

Standard packaging includes anti-static bags and cartons. Custom labeling with barcodes, model numbers, and logos is available upon request. OEM packaging with private branding is supported by manufacturers offering full customization services.