Inductive Proximity Sensors

Top sponsor listing

Top sponsor listing

1/5

1/5

1/42

1/42

1/37

1/37

1/58

1/58

About inductive proximity sensors

Where to Find Inductive Proximity Sensor Suppliers?

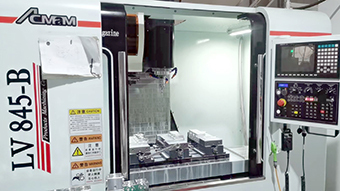

China remains a central hub for inductive proximity sensor manufacturing, with key production clusters in Shanghai, Suzhou, and Yueqing offering robust industrial ecosystems. These regions host vertically integrated supply chains encompassing coil winding, shielding, encapsulation, and final assembly, enabling rapid prototyping and scalable output. Shanghai and Suzhou specialize in high-volume OEM/ODM production, supported by advanced automation and precision machining capabilities. Yueqing, known as China’s low-voltage electrical equipment base, provides cost-efficient manufacturing with access to dense networks of component suppliers.

The concentration of technical expertise and supporting infrastructure allows suppliers to maintain competitive lead times—typically 15–25 days for standard orders and 30–45 days for customized configurations. Localized sourcing of core materials such as copper coils, ferrite cores, and nickel-plated brass housings reduces material costs by 15–25% compared to Western counterparts. Buyers benefit from flexible MOQs, ranging from single-piece sampling to container-scale procurement, alongside widespread support for international certifications including CE, RoHS, and ISO 9001 compliance.

How to Choose Inductive Proximity Sensor Suppliers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Technical and Quality Compliance

Verify adherence to international standards such as IEC 60947-5-2 for switchgear and control gear. Prioritize suppliers with documented quality management systems (ISO 9001) and product-level certifications (CE, RoHS). Request test reports covering operational reliability, temperature tolerance (-25°C to +70°C typical), and electromagnetic compatibility (EMC).

Production and Customization Capability

Assess engineering flexibility and process control through the following indicators:

- In-house tooling and molding facilities for housing and coil fabrication

- Support for customization in detection distance (2–50mm), output type (NPN/PNP), voltage (10–30V DC), and connection method (cable, connector, M8/M12)

- Capacity for laser marking, color coding, and packaging labeling per client specifications

Cross-reference online revenue data and reorder rates to gauge market acceptance and operational stability.

Transaction Reliability and Responsiveness

Evaluate responsiveness (target ≤3 hours) and on-time delivery performance (ideal ≥97%). Favor suppliers with transparent communication channels, documented dispute resolution processes, and participation in transaction protection programs. Pre-shipment inspection rights and sample validation should be contractually secured prior to bulk ordering.

What Are the Best Inductive Proximity Sensor Suppliers?

| Company Name | Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Shanghai Lanbao Sensing Technology Co., Ltd. | Custom Manufacturer | Proximity Sensors, Optical Sensors, Ultrasonic Sensors | US $620,000+ | 99% | ≤2h | 17% | 14+ SKUs | Yes (size, shape, cable, labeling, temp range) |

| Dexinzheng Electronic (Suzhou) Co., Ltd. | Proximity Sensors, Solid State Relays, Optical Sensors | US $10,000+ | 100% | ≤3h | <15% | 3 SKUs | Limited | |

| Yueqing Chengfei Electric Co., Ltd. | Proximity Sensors, Push Button Switches, Relays | US $9,000+ | 100% | ≤1h | <15% | 5 SKUs | Basic (cable length, output type) | |

| Beijing Shuntu Technology Co., Ltd. | Proximity Sensors, Push Button Switches, Relays | US $100,000+ | 97% | ≤3h | 22% | 4 SKUs | No (reseller model) | |

| Simplybuy (Shanghai) Co., Ltd. | Multispecialty Supplier | Inductive & Capacitive Sensors, Brand Distribution | US $420,000+ | 90% | ≤3h | 31% | 5 SKUs | Yes (label, packaging, graphic) |

Performance Analysis

Shanghai Lanbao stands out as a dedicated manufacturer with extensive customization options, high online revenue, and strong delivery reliability, making it suitable for OEM partnerships. Dexinzheng and Yueqing Chengfei offer fast response times and perfect on-time delivery records, ideal for time-sensitive procurement despite lower reorder rates indicating limited customer retention. Beijing Shuntu demonstrates mid-tier performance with moderate reorder activity and reliable fulfillment, though its product range suggests a distribution-focused model. Simplybuy exhibits the highest reorder rate (31%), reflecting strong buyer satisfaction, but its 90% on-time delivery rate presents a risk for mission-critical applications. Buyers seeking branded or compatible replacements may consider resellers, while those requiring proprietary designs should prioritize custom manufacturers with in-house R&D and tooling.

FAQs

How to verify inductive proximity sensor supplier reliability?

Cross-check ISO and CE claims with certification databases. Request factory audit reports or video tours to confirm production lines and quality control stations. Analyze transaction history, focusing on consistent on-time delivery (>97%) and responsive communication.

What is the typical MOQ and lead time?

MOQ ranges from 1 piece for samples to 100+ units for bulk orders. Standard lead time is 15–25 days; customized sensors may require 30–45 days depending on design complexity and tooling requirements.

Do suppliers support customization?

Yes, leading manufacturers support modifications in detection range, body diameter (M3 to M30), cable length (0.5m to 5m), output signal (analog/digital, NPN/PNP), and environmental ratings (IP67/IP68). Custom labeling and packaging are widely available.

Can suppliers provide certified test reports?

Reputable suppliers issue internal test reports for insulation resistance, dielectric strength, and operational cycle testing (typically 1 million cycles). Third-party lab verification can be requested at additional cost.

What are common export destinations?

Key markets include North America, Germany, Turkey, India, and Southeast Asia. Suppliers with export experience typically comply with regional EMC and safety directives and offer FOB, CIF, or DAP shipping terms.