Industrial Automation Solution

Top sponsor listing

Top sponsor listing

About industrial automation solution

Where to Find Industrial Automation Solution Suppliers?

China leads global production of industrial automation solutions, with key manufacturing hubs concentrated in Guangdong and Shandong provinces. Guangdong’s Pearl River Delta region hosts advanced robotics and control systems manufacturers, supported by a dense network of electronics component suppliers and R&D centers. This ecosystem enables rapid prototyping and integration of servo drives, PLCs, and robotic arms within compact supply chains. Shandong's Qingdao and Jinan zones specialize in heavy industrial automation systems, particularly turnkey welding lines and material handling robots, leveraging proximity to steel and machinery processing clusters for cost-efficient fabrication.

These regions offer vertically integrated capabilities—from PCB assembly to full system commissioning—allowing suppliers to deliver complete automation cells with lead times averaging 45–60 days for standard configurations. Buyers benefit from localized sourcing of motors, inverters, and structural components, reducing logistics overhead by 18–25% compared to offshore alternatives. The clusters support both high-volume deployments and low-MOQ custom builds, with many facilities equipped for modular production of AGVs, articulated robots, and precision pick-and-place units.

How to Choose Industrial Automation Solution Suppliers?

Apply rigorous evaluation criteria when selecting automation partners:

Technical Compliance & Certifications

Verify ISO 9001 certification as a baseline for quality management. For export markets, confirm CE marking compliance for electrical safety (EN 60204-1) and EMC standards. Suppliers integrating motion control systems should provide documentation for RoHS compliance and functional safety validation (e.g., SIL ratings for safety relays). Request test reports on cycle life, positioning accuracy, and thermal performance under load conditions.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum 3,000m² factory area for dedicated robot or control panel assembly lines

- In-house engineering team capable of system design, offline programming, and HMI development

- Integrated testing bays with load simulation and path accuracy verification tools

Cross-reference on-time delivery rates (>95%) and response time (<4 hours) with order volume trends to assess operational stability.

Customization & Transaction Safeguards

Confirm customization scope: leading suppliers support modifications to payload capacity, reach radius, color coding, labeling, and communication protocols (Modbus, Profibus, EtherCAT). Require milestone-based payment terms with third-party inspection clauses prior to shipment. Prioritize suppliers with documented after-sales service procedures, including remote diagnostics and spare parts availability.

What Are the Best Industrial Automation Solution Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Product Range |

|---|---|---|---|---|---|---|---|

| Guangdong Jiesheng Electric Technology Co., Ltd. | Custom Manufacturer | Variable Frequency Drivers, AC Motors, Inverters & Converters | 100% | 46% | ≤1h | US $40,000+ | 5 products |

| Shandong UMW Technology Co., Ltd. | Multispecialty Supplier | 6-Axis Robot Arms, Welding Systems, Precision Grinding Robots | 100% | 28% | ≤2h | US $680,000+ | 5 products |

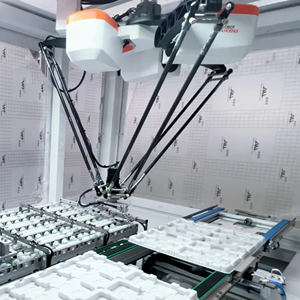

| Robotphoenix Intelligent Technology Co.,Ltd | Manufacturer | Delta Parallel Robots, AGVs, Pick-and-Place Systems | 100% | 100% | ≤3h | US $30,000+ | 5 products |

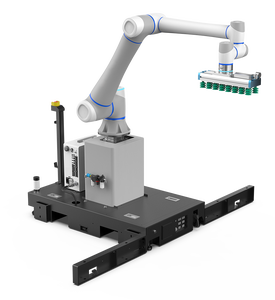

| Guangdong Borunte Robot Technology Co., Ltd. | Manufacturer | Articulated Robots, Collaborative Robots, Electric Grippers | 75% | 50% | ≤3h | US $20,000+ | 4 products |

| Stuaa Automation (qingdao) Co., Ltd. | Manufacturer | Turnkey Welding Lines, Pipe Flange Automation, Offline Programming Systems | 100% | - | ≤5h | - | 5 products |

Performance Analysis

Guangdong Jiesheng and Shandong UMW demonstrate strong delivery reliability (100% on-time), with UMW offering higher transaction volume, indicating scalability for large-scale automation rollouts. Robotphoenix stands out with a 100% reorder rate, suggesting high customer satisfaction in AGV and delta robot applications. Borunte shows moderate delivery performance (75%), which may reflect capacity constraints despite diverse product offerings. Stuaa Automation specializes in high-value turnkey systems ($300,000+), targeting niche industrial welding automation with full-line integration expertise. Buyers seeking responsive support should prioritize Guangdong-based suppliers, where 60% respond within 3 hours.

FAQs

What is the typical MOQ for industrial automation systems?

Most suppliers list MOQ at 1 set for robotic arms and automation cells. Control components like VFDs and inverters may have lower MOQs (1–5 units). Volume discounts typically apply starting at 5–10 units for standardized models.

How long does it take to receive a sample or prototype?

Standard robot or controller samples require 20–35 days for production. Custom configurations involving mechanical redesign or software integration extend timelines to 6–8 weeks. Air freight adds 5–10 days for international delivery.

Do suppliers support OEM/ODM services?

Yes, most suppliers listed offer ODM customization including logo branding, color schemes, packaging labels, and interface localization. Advanced partners provide full OEM development with private-labeled HMI screens and proprietary control logic implementation.

Are industrial automation solutions export-ready?

Established suppliers prepare systems for international deployment, including voltage adaptation (380V/480V), CE-compliant documentation, and multilingual manuals. Confirm inclusion of customs clearance packages and compatibility with local grid and safety standards before shipment.

How to validate system performance before procurement?

Request video demonstrations of operational cycles, path accuracy tests, and load endurance runs. Reputable suppliers provide 3D models and simulation files (e.g., STEP, STL, RoboDK projects) within 72 hours. Onsite or virtual factory audits are recommended for orders exceeding $50,000 to verify build quality and testing protocols.