Industries That Use Robots In Manufacturing

Top sponsor listing

Top sponsor listing

1/5

1/5

1/2

1/2

1/33

1/33

CN

CN

1/12

1/12

About industries that use robots in manufacturing

Which Industries Utilize Robots in Manufacturing?

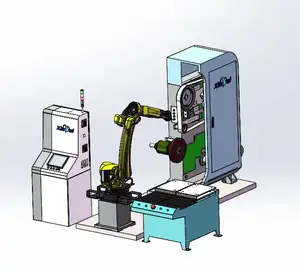

Robots have become integral to modern manufacturing across diverse industrial sectors, enabling automation of repetitive, precision-sensitive, and hazardous tasks. Key industries leveraging robotic systems include automotive, electronics, food and beverage, pharmaceuticals, logistics, and metal fabrication. The integration of robotics enhances production efficiency, ensures consistent product quality, and reduces operational downtime. In high-mix, low-volume environments such as electronics assembly, collaborative robots (cobots) support human workers with precision handling of small components. Meanwhile, heavy industries like automotive manufacturing deploy articulated robots for welding, painting, and material handling at scale.

The global shift toward smart factories and Industry 4.0 has accelerated demand for adaptable robotic solutions capable of real-time data exchange, machine vision integration, and autonomous decision-making. Suppliers are responding with modular robotic arms, AI-powered grippers, and mobile delivery units tailored to specific process requirements. As labor costs rise and supply chain resilience becomes critical, manufacturers increasingly invest in robotic automation to achieve faster cycle times, reduce error rates, and maintain competitive advantage in international markets.

How to Evaluate Suppliers of Robots for Manufacturing?

Selecting a reliable supplier requires a structured assessment of technical capability, production capacity, and transactional reliability:

Technical Expertise and Product Range

Prioritize suppliers offering documented expertise in the specific robot type required—such as articulated, SCARA, parallel, or collaborative models. Verify that core components like servo motors, controllers, and end-effectors are developed in-house or sourced from certified partners. Suppliers should provide detailed specifications including payload capacity, repeatability, degrees of freedom, and compatibility with common industrial communication protocols (e.g., Modbus, Profibus).

Quality Assurance and Compliance

Confirm adherence to internationally recognized standards such as ISO 9001 for quality management. For deployment in regulated environments (e.g., medical device manufacturing), CE marking and compliance with machinery safety directives (EN ISO 13849) are essential. Request test reports for electromagnetic compatibility (EMC), environmental durability, and functional safety where applicable.

Production and Customization Capabilities

Assess scalability through key indicators:

- Minimum factory area exceeding 3,000m² to support dedicated R&D and assembly lines

- In-house design and prototyping capabilities for custom grippers, tool changers, or application-specific programming

- Proven experience with OEM/ODM projects and integration into existing production workflows

Cross-reference online revenue metrics and reorder rates to evaluate customer retention and service performance.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services until acceptance testing is completed. Require full documentation packages including user manuals, wiring diagrams, and software development kits (SDKs). Conduct pre-shipment inspections or virtual factory audits to validate production status and quality control procedures. Sample testing is recommended to assess ease of integration, path accuracy, and long-term stability under simulated operating conditions.

Top Suppliers of Robots for Manufacturing

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options | Type |

|---|---|---|---|---|---|---|---|

| Ningbo Vichnet Technology Co., Ltd. | Fencing, Trellis & Gates, Cable Trays, Locks | 100% | 62% | ≤2h | US $630,000+ | Yes | Custom Manufacturer |

| Guangdong Borunte Robot Technology Co., Ltd. | Articulated Robots, Collaborative Robots, Parallel Robots | 66% | 100% | ≤3h | US $20,000+ | Yes | Manufacturer |

| Changingtek Robotics Technology (Suzhou) Co., Ltd. | Collaborative Robots, Articulated Robots, Electric Grippers | 100% | 33% | ≤2h | US $6,000+ | Yes | Manufacturer |

| Shanghai Mi City Industrial Co., Ltd. | Commercial Delivery Robots, Logistics Robots, Reception Robots | 100% | 15% | ≤2h | US $370,000+ | Yes | Manufacturer |

| Dongguan Chuanlida Intelligent Equipment Co., Ltd. | Articulated Robots | 100% | <15% | ≤3h | US $30,000+ | Limited | Manufacturer |

Performance Analysis

Guangdong Borunte stands out with a 100% reorder rate, indicating strong customer satisfaction despite a lower on-time delivery score (66%), suggesting potential logistics bottlenecks. Ningbo Vichnet combines high fulfillment reliability (100% on-time delivery) with robust customization options and the highest reported online revenue, positioning it as a scalable partner for complex automation projects. Changingtek Robotics offers specialized components such as bionic fingers and electric grippers, catering to advanced cobot integrations. Shanghai Mi City targets niche commercial applications but maintains strong responsiveness and delivery consistency. Dongguan Chuanlida focuses exclusively on articulated robots with repeatable performance, though limited reorder activity suggests narrower market penetration. Buyers seeking turnkey solutions should prioritize suppliers with comprehensive product ecosystems and proven integration support.

FAQs

What are the typical MOQ and pricing for industrial robots?

Minimum order quantities typically start at 1 unit for standard configurations. Pricing varies by type: entry-level robotic arms range from $999–$2,000, while high-precision or six-axis models can exceed $11,500 per set. Mobile and humanoid systems may cost up to $100,000 depending on functionality.

How long does it take to fulfill a robot order?

Standard lead times range from 15 to 30 days after confirmation of technical specifications. Customized systems requiring software adaptation or mechanical redesign may require 45–60 days. Expedited production is available from select suppliers with in-house machining and control system assembly.

Can robots be customized for specific manufacturing processes?

Yes, most suppliers offer customization in payload, reach, mounting configuration, IP rating, and software interface. End-of-arm tooling (EOAT), including grippers and sensors, can be engineered to match part geometry and handling requirements. Some manufacturers provide SDKs for seamless PLC or MES integration.

Do suppliers provide technical support and training?

Reputable manufacturers offer remote troubleshooting, programming assistance, and installation guidance. Advanced vendors provide on-site commissioning support and operator training programs, either virtually or on location, to ensure smooth deployment.

Are there export controls or shipping considerations for industrial robots?

Robotic systems classified under dual-use regulations (e.g., high-speed autonomous units) may require export licenses. Standard packaging includes wooden crates with shock-absorbing materials. Air freight is suitable for single units (7–10 days transit); sea freight is economical for bulk shipments (20–35 days).