Internal And External Suppliers Examples

CN

CN

About internal and external suppliers examples

Where to Find Internal and External Suppliers Examples?

The global supply base for components illustrating internal and external supplier relationships is concentrated in specialized industrial hubs across China, particularly in Beijing, Shenzhen, Wenzhou, and Guangdong. These regions host vertically integrated manufacturing ecosystems that support both high-precision component fabrication and comprehensive sourcing services. Beijing and Shenzhen are key centers for electronic and technology hardware, leveraging advanced BOM (Bill of Materials) assembly lines and semiconductor logistics networks. Meanwhile, Wenzhou specializes in fluid control systems and stainless steel mechanical fittings, benefiting from localized metallurgical supply chains and precision machining clusters.

These regional advantages translate into operational efficiencies, including reduced material lead times, access to certified production facilities, and scalable output capacity. Suppliers in these zones typically operate within tightly coordinated networks—integrating raw material processing, CNC turning, threading, surface treatment, and final assembly—enabling rapid prototyping and volume fulfillment. Buyers can expect lead times ranging from 7–20 days for standard orders, with cost savings of 15–30% compared to Western-based manufacturers due to lower labor and overhead costs and streamlined export infrastructure.

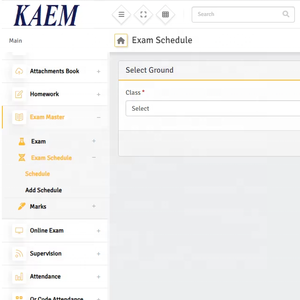

How to Choose Internal and External Suppliers Examples?

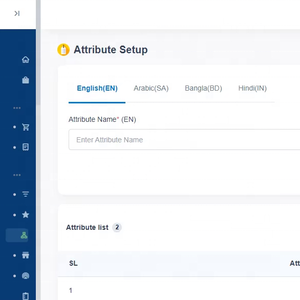

Selecting reliable suppliers requires a structured evaluation framework focused on operational transparency, technical capability, and transactional reliability:

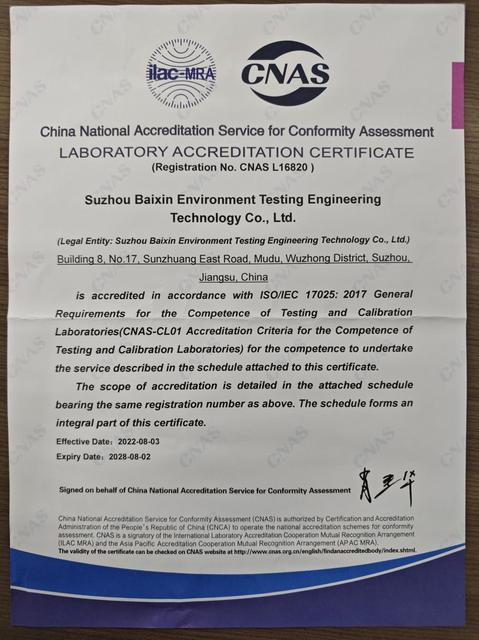

Quality Assurance & Compliance

Prioritize suppliers with documented quality management systems. While formal certifications such as ISO 9001 or RoHS compliance are not explicitly stated in available data, consistent on-time delivery performance (100% reported by multiple suppliers) indicates adherence to internal quality controls. For electronics and connector components, verify material specifications, plating standards, and electrical tolerance testing protocols prior to procurement.

Production & Customization Capacity

Assess supplier flexibility based on service scope:

- Capability for OEM/ODM customization—including logo printing, packaging design, color variation, and dimensional adjustments

- Minimum order quantities (MOQs) ranging from 2 to 10,000 pieces depending on product type

- Use of precision techniques such as CNC threading, wire forming, and brazed joint fabrication for mechanical parts

- BOM-level integration services for electronic sub-assemblies requiring multi-component sourcing

Cross-reference customization claims with product-specific MOQs and pricing tiers to assess scalability.

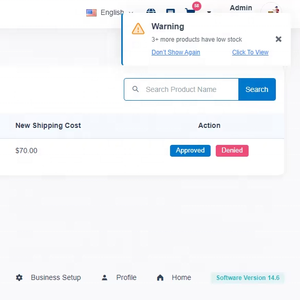

Transaction Reliability Metrics

Analyze performance indicators derived from transaction histories:

- On-time delivery rates: Top-tier suppliers report 100% fulfillment

- Average response time: Ranges from ≤2 hours to ≤23 hours; prioritize partners responding within 6 hours

- Reorder rates: Below 15% for most suppliers, indicating niche or project-based client engagement; one supplier reports 33%, suggesting stronger customer retention

- Online revenue: Varies from US $4,000+ to US $40,000+, reflecting differing sales volumes and market reach

Low reorder rates may indicate specialized or one-off sourcing arrangements rather than recurring supply contracts.

What Are the Best Internal and External Suppliers Examples?

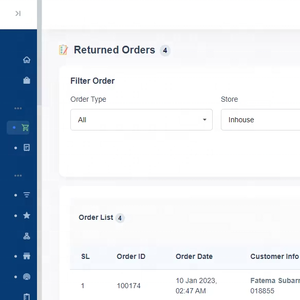

| Company Name | Main Products | Price Range | Min. Order | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

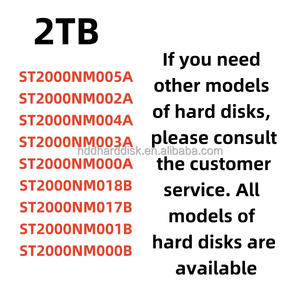

| Beijing Yuanshengyuan Technology Co., Ltd. | Enterprise SSDs, Storage Devices | $155–550 | 1 piece | 100% | ≤2h | <15% | US $20,000+ | Color, material, size, logo, packaging, label, graphic |

| Wenzhou Huangchuang Fluid Equipment Co., Ltd. | Stainless Steel Threaded Fittings, Wire Joints | $0.50–1.00 | 10 pieces | 100% | ≤6h | 33% | US $10,000+ | Not specified |

| Shenzhen Biguang Tech Co., Ltd. | BOM Services, Connectors, Power Modules | $0.67–23.58 | 2 pieces | 100% | ≤2h | <15% | US $4,000+ | Not specified |

| MEKONG DELTA IMPORT EXPORT COMPANY LIMITED | Sourcing Services, Garments, Crafts | $0.05–3.00 | 1,000–100,000 pieces | Not available | ≤23h | Not available | Not available | Not specified |

| POLARTRONIC CO., LIMITED | Internal/External SSDs, Enterprise Storage | $266–500 | 1 piece | 100% | ≤7h | Not available | US $40,000+ | Not specified |

Performance Analysis

Beijing- and Shenzhen-based technology suppliers excel in responsiveness (≤2h) and offer low MOQs ideal for prototype or replacement part sourcing. POLARTRONIC CO., LIMITED stands out with the highest reported online revenue (US $40,000+), suggesting robust export activity and product demand. Wenzhou Huangchuang Fluid Equipment demonstrates strong customer retention with a 33% reorder rate, indicating reliable execution in the mechanical components sector. Suppliers offering customization—particularly Beijing Yuanshengyuan—provide added value for branded or integrated system deployments. However, limited certification data and inconsistent reorder metrics highlight the need for direct verification before long-term contracting.

FAQs

How to verify supplier reliability for internal and external components?

Request evidence of quality control processes, including inspection checklists, material test reports, and packaging standards. For electronic assemblies, confirm traceability of components through BOM documentation. Use video audits to validate facility operations and inventory management practices.

What are typical minimum order quantities?

MOQs vary significantly: 1 piece for enterprise SSDs, 2 pieces for power connectors, 10 pieces for threaded fittings, and up to 100,000 pieces for garment sourcing agents. Low MOQs facilitate sampling and small-batch procurement but may incur higher per-unit costs.

Do suppliers support product customization?

Yes, select suppliers—such as Beijing Yuanshengyuan Technology—offer extensive customization, including branding, labeling, color, and packaging modifications. Confirm feasibility and incremental costs during initial inquiry stages.

Are samples available before bulk ordering?

While not explicitly stated, suppliers with low MOQs (e.g., 1–2 pieces) effectively allow sample acquisition at near-production pricing. Factor in shipping and import duties when evaluating sample costs.

What are common applications for these components?

Products serve diverse sectors: stainless steel fittings for plumbing and industrial fluid systems; BOM-integrated connectors for power distribution and automation; SSDs for enterprise data storage; and sourcing services for consumer goods supply chain management. Applications illustrate real-world models of internal (in-house production) versus external (third-party procurement) supply strategies.