Jyoti Cnc Lathe Machine Price

About jyoti cnc lathe machine price

Where to Find CNC Lathe Machine Suppliers?

China remains the dominant force in global CNC lathe machine manufacturing, with key industrial clusters concentrated in Hebei, Guangdong, and Shandong provinces. These regions host vertically integrated production ecosystems that combine precision machining, casting, and control system integration within compact geographic zones. Hebei’s machinery corridor supports high-volume output through proximity to steel and casting suppliers, reducing raw material lead times by 20–30%. Meanwhile, Guangdong-based manufacturers leverage advanced automation and export logistics via the Pearl River Delta, enabling faster delivery cycles for international buyers.

The sector benefits from mature supply chains where component sourcing, heat treatment, linear guide rail assembly, and servo motor integration occur within localized networks. This infrastructure supports rapid prototyping and scalable production, with standard lead times averaging 30–45 days for non-custom units. Buyers gain access to competitive pricing structures—driven by 15–25% lower labor and operational costs compared to European or North American producers—while maintaining technical parity in spindle accuracy (±0.005mm) and surface finish quality (Ra 1.6μm).

How to Choose CNC Lathe Machine Suppliers?

Selecting reliable partners requires systematic evaluation across three critical dimensions:

Technical Capability Verification

Confirm suppliers possess in-house CNC machining centers, gear hobbing equipment, and spindle balancing systems. Prioritize companies demonstrating multi-axis turning capacity (e.g., dual-spindle, Y-axis milling, or live tooling configurations). For Jyoti-compatible models or functionally equivalent machines, verify compatibility with Fanuc, Siemens, or GSK control systems. ISO 9001 certification should be treated as a baseline requirement for process standardization.

Production Infrastructure Assessment

Evaluate operational scale using measurable indicators:

- Minimum factory footprint of 3,000m² to ensure batch production stability

- In-house engineering teams capable of executing drawing-based customization

- Integrated lubrication, cooling, and chip removal system assembly lines

Cross-reference online transaction volumes and reorder rates with on-time delivery performance to assess fulfillment reliability.

Procurement Risk Mitigation

Utilize secure payment frameworks such as trade assurance or escrow services until post-delivery inspection is completed. Request sample units for dimensional accuracy, runout testing, and thermal stability under continuous load. Analyze supplier responsiveness (target ≤3 hours), historical reorder rates (>25% indicates customer retention), and after-sales support scope—including technician training and spare parts availability.

What Are the Best CNC Lathe Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

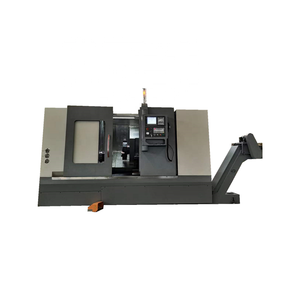

| Hebei Yawo Machinery Manufacturing Co., Ltd. | Hebei, CN | Manual Lathe, CNC Lathe | US $10,000+ | - | ≤3h | 100% | $11,500–21,500 | No |

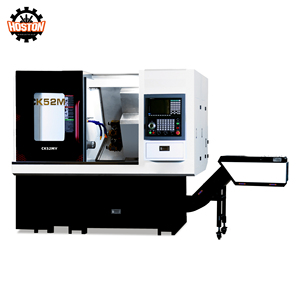

| Foshan Sds Smart Tech Co., Ltd. | Guangdong, CN | Slant Bed CNC Lathe, Dual Spindle | US $410,000+ | 100% | ≤2h | 25% | $4,999–38,480 | Yes |

| Guangzhou Qiangyuan Cnc Machinery Co., Ltd. | Guangdong, CN | CNC Lathe, Milling Machines | US $500+ | 100% | ≤3h | <15% | $4,500–10,500 | Yes |

| Shanghai Sumore Industrial Co., Ltd. | Shanghai, CN | Bench CNC Lathe, Mini Lathe | US $60,000+ | 100% | ≤3h | 25% | $1,699–6,299 | Yes |

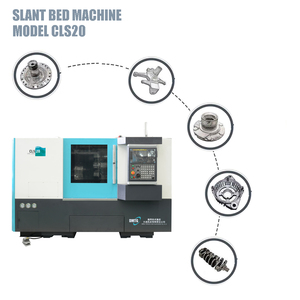

| Zaozhuang Wojie CNC Machinery Co., Ltd. | Shandong, CN | Flat Bed, Vertical CNC Lathe | US $520,000+ | 100% | ≤2h | 33% | $8,700–33,282 | Yes |

Performance Analysis

Zaozhuang Wojie and Foshan SDS demonstrate strong technical scalability, supported by high online transaction volumes (exceeding US$400,000 annually) and sub-2-hour response times. Foshan SDS stands out for extensive customization capabilities, including dual-spindle setups, servo bar feeders, and simulation-based oil mist collection systems. Hebei Yawo reports a 100% reorder rate despite limited customization, suggesting niche reliability in standardized horizontal lathes like CK61125/CK61160 series. Shanghai Sumore targets entry-level and educational markets with bench-top models priced below $2,000, offering flexibility in control systems and chuck configurations. Guangzhou Qiangyuan provides mid-range solutions ideal for small workshops requiring 3-axis automation at competitive price points ($4,500–$10,500).

FAQs

How to verify CNC lathe machine supplier credibility?

Validate ISO 9001 certification status through accredited registrars. Request documented evidence of spindle runout tests (≤0.003mm TIR), guideway parallelism checks, and vibration analysis reports. Review third-party transaction histories focusing on dispute resolution outcomes and shipment adherence.

What is the typical minimum order quantity (MOQ)?

All listed suppliers offer MOQs of 1 set, facilitating low-risk procurement for pilot testing or single-unit deployment. Bulk discounts typically apply at 3+ units, with negotiated freight options available for containerized shipments.

Are customization requests feasible?

Yes—four of five top suppliers provide configuration options including servo turrets, hydraulic chucks, multi-spindle layouts, and custom programming interfaces. Submit detailed mechanical drawings and functional requirements to receive feasibility assessments within 72 hours.

What are standard lead times for CNC lathe orders?

Standard models ship within 30–40 days after deposit confirmation. Custom-engineered units require 45–60 days depending on complexity. Air freight samples can be arranged in 15–20 days for urgent evaluations.

Do suppliers support global shipping and installation?

Yes, experienced exporters manage FOB and CIF terms with documentation compliant with CE, RoHS, and destination-specific electrical standards. Pre-shipment commissioning and remote setup assistance are commonly offered; on-site technician dispatch may incur additional fees.