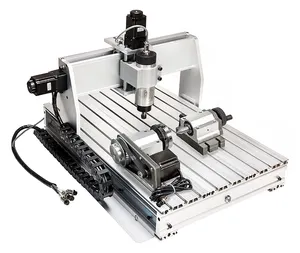

Jyoti Cnc Machine Price In India

About jyoti cnc machine price in india

Where to Find Jyoti CNC Machine Suppliers in India?

China remains a dominant force in the global CNC machine manufacturing sector, with key industrial hubs in Jiangsu, Shandong, and Guangdong provinces offering competitive advantages for international buyers. These regions host vertically integrated supply chains that support rapid prototyping, high-volume production, and cost-efficient component sourcing—particularly in precision machining centers and control systems. While "Jyoti" refers to an Indian brand of CNC equipment, multiple Chinese manufacturers produce functionally comparable machines marketed under similar performance specifications, often at significantly lower price points.

Suppliers from Nanjing, Jinan, and Changzhou leverage localized ecosystems encompassing casting, linear guide production, spindle assembly, and CNC controller integration. This clustering reduces lead times by up to 30% compared to decentralized manufacturing models. Buyers sourcing machines equivalent to Jyoti CNC models benefit from established export channels, with average delivery windows ranging from 25–40 days for standard configurations. Cost savings typically range between 20–40% versus domestically produced Indian units, driven by economies of scale and direct factory-to-buyer transaction models.

How to Choose Jyoti CNC Machine Equivalent Suppliers?

Selecting reliable suppliers requires adherence to structured evaluation criteria focused on technical capability, quality assurance, and transactional reliability.

Technical Specification Alignment

Ensure machine parameters (e.g., spindle power, table size, axis travel, control system type—SYNTEC, Fanuc, or Mach3) match those of Jyoti models such as VMC600 or GMC3018. Verify compatibility with ISO-standard tooling and G-code programming environments. Request full technical datasheets including dynamic accuracy tests, backlash measurements, and thermal stability reports.

Quality Management Verification

Prioritize suppliers with CE certification and ISO 9001 compliance, which indicate adherence to standardized quality control processes. For enhanced assurance, request evidence of in-house testing protocols for critical components like ball screws, linear guides, and servo motors. Machines priced below $10,000 should be scrutinized for material substitution risks (e.g., aluminum housings instead of cast iron).

Production Capacity Assessment

Evaluate operational scale through objective metrics:

- Facility area exceeding 5,000m² to ensure volume output capacity

- In-house machining capabilities for bed casting, milling, and grinding

- Dedicated R&D teams supporting customization and software integration

Cross-reference claimed production capacity with verified on-time delivery rates above 95% and response times under 4 hours.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services tied to shipment milestones. Insist on pre-shipment inspection clauses allowing third-party verification of machine calibration and run testing. Sample orders are recommended for new supplier relationships—benchmark surface finish accuracy and positional repeatability against ISO 230-2 standards before scaling procurement.

What Are the Leading Jyoti CNC Machine Alternative Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Nanjing High Tech Machinery Co., Ltd. | Machining Centre, CNC Lathe, Linear Guides | $15,999–27,685 | 1 set/piece | 87% | ≤7h | <15% | US $4,000+ |

| Jinan Renxi Technology Co., Ltd. | Wood Routers, Laser Cutters, Plasma CNC | $1,500–2,000 | 1 set | 100% | ≤2h | <15% | US $30,000+ |

| Shandong Yijin Cnc Machine Tool Co., Ltd. | Machining Centre, Manual Mills, Boring Machines | $11,000–49,999 | 1 set | 100% | ≤1h | 50% | US $40,000+ |

| Changzhou Handi Motor Science And Technology Co., Ltd. | Mini CNC Mills, Spindles, VFDs | $490–1,090 | 1 piece | 100% | ≤3h | <15% | US $40,000+ |

| Jinan Changtai CNC Technology Co., Ltd. | Woodworking CNC, Laser Cutters, Metal Routers | $3,200–85,000 | 1 set/piece | 100% | ≤2h | 18% | US $480,000+ |

Performance Analysis

Shandong Yijin stands out for its high reorder rate (50%) and consistent on-time delivery, indicating strong customer satisfaction despite higher pricing tiers. Jinan-based suppliers demonstrate superior responsiveness, with three companies achieving sub-3-hour average reply times and perfect on-time fulfillment records. Nanjing High Tech offers mid-range machines aligned with Jyoti VMC600 specifications but exhibits a relatively low reorder rate, suggesting potential gaps in after-sales service or long-term reliability. For budget-conscious buyers, Changzhou Handi provides entry-level desktop CNC solutions ideal for prototyping, though not suitable for continuous industrial use. Jinan Changtai’s broad product range and high online revenue reflect extensive export experience and scalability.

FAQs

Are these machines compatible with Jyoti CNC part programs?

Yes, if equipped with compatible control systems (e.g., SYNTEC or Fanuc). Most suppliers offer G-code compliant machines that can run standard NC files used in Indian-manufactured Jyoti systems. Confirm controller model and post-processor settings prior to integration.

What is the typical lead time for CNC machine orders?

Standard machines ship within 20–35 days after order confirmation. Customized models requiring non-standard spindles, extended tables, or specialized cooling systems may require 45–60 days. Air freight options reduce transit time to 5–10 days but increase logistics costs by 200–300%.

Do suppliers offer installation and training support?

Support varies. Some suppliers include remote setup assistance via video call; others charge extra for on-site technician deployment. Clarify terms during negotiation. Documentation is typically provided in English, covering maintenance schedules and error code diagnostics.

Can I customize the machine for specific materials?

Yes. Reputable suppliers allow modifications to spindle power (3–15kW), tool changer type (ATC or manual), coolant systems, and workholding fixtures. Provide detailed processing requirements (e.g., titanium milling vs. acrylic routing) to receive accurate configuration recommendations.

What are common MOQ and payment terms?

MOQ is typically 1 unit for standard models. Payment structures usually involve 30% advance T/T, balance before shipment. Letters of Credit (L/C) are accepted by larger exporters. Trade Assurance-backed transactions provide added security for first-time buyers.