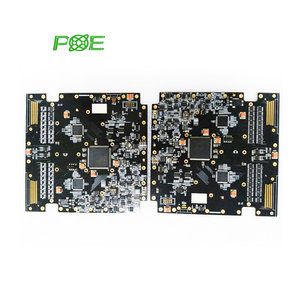

Keyboard Pcb Maker

About keyboard pcb maker

Where to Find Keyboard PCB Maker Suppliers?

China leads global production of custom keyboard PCBs, with concentrated manufacturing hubs in Shenzhen, Guangzhou, and Suzhou offering specialized capabilities for mechanical keyboard applications. These regions host vertically integrated facilities combining PCB fabrication, SMT assembly, and design engineering under one roof, enabling rapid prototyping and scalable production. Shenzhen and Guangdong-based suppliers benefit from proximity to component distributors and logistics networks, reducing material lead times by 20–30% compared to offshore alternatives.

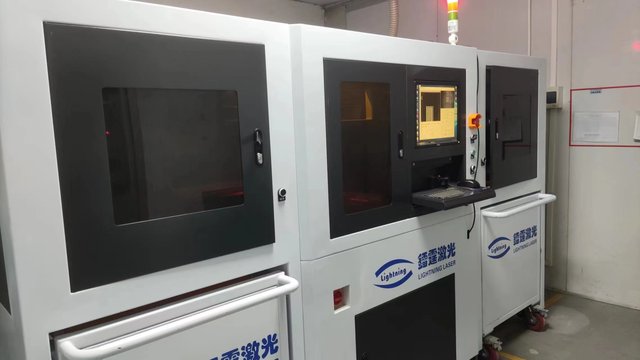

The industrial ecosystem supports both low-volume customization and high-volume manufacturing, with many suppliers operating automated SMT lines capable of producing over 10,000 units monthly. Buyers gain access to flexible production models—ranging from single-piece prototypes to bulk orders exceeding 10,000 units—with typical lead times between 5–15 days for sample batches and 20–30 days for full-scale production. Localized supply chains also enable cost efficiencies, with average unit prices ranging from $0.10 to $8.30 depending on complexity, layer count, and order volume.

How to Choose Keyboard PCB Maker Suppliers?

Key evaluation criteria should include technical capability, quality assurance practices, and transaction reliability:

Design & Manufacturing Capability

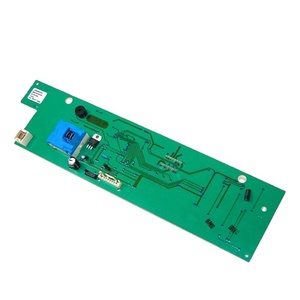

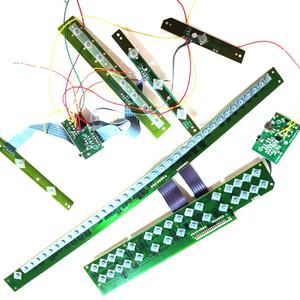

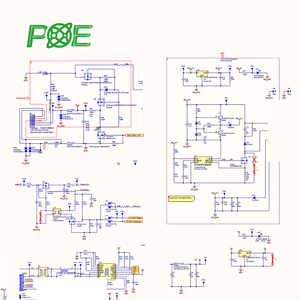

Verify support for common keyboard PCB specifications: FR4 substrates, 2–4 layer boards, hot-swap compatibility, and USB-HID firmware integration. Suppliers should offer full turnkey services including schematic capture, layout design (using tools like KiCad or Altium), and prototype validation. Prioritize those with in-house SMT lines and testing protocols such as AOI (Automated Optical Inspection) and functional testing.

Quality Assurance Standards

While formal ISO 9001 certification is not universally listed, assess compliance through documented QC processes. Look for evidence of IPC-A-610 standards adherence, solder joint inspection, and continuity testing. For export-bound electronics, ensure RoHS compliance and lead-free processing capabilities. Request test reports or video verification of assembled boards prior to shipment.

Production Flexibility and Scalability

Evaluate minimum order quantities (MOQs), which range from 1 piece (ideal for hobbyist or prototype sourcing) to 10,000 pieces for optimized pricing. Confirm scalability by reviewing supplier output capacity and reorder rates. Cross-reference response times (typically ≤5 hours) and on-time delivery performance—suppliers reporting ≥94% on-time fulfillment are preferred for time-sensitive projects.

What Are the Best Keyboard PCB Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Mingde Denso Technology Co., Ltd. | Shenzhen, CN | High Frequency PCB (154), PCBA (39) | - | - | ≤4h | <15% | 1,000 pcs | $4.60–30.10 |

| Suzhou Engine Electronic Technology Co., Ltd. | Suzhou, CN | Customization-focused PCB/PCBA | US $50,000+ | 91% | ≤3h | <15% | 1 pc | $0.30–0.50 |

| Guangdong Global Well Electronic Limited | Guangdong, CN | PCBA (245), Multilayer PCB (13) | US $60,000+ | 100% | ≤5h | 33% | 1 pc | $0.30–4.50 |

| Huizhou Linghangda Technology Co., Ltd. | Huizhou, CN | PCBA (28), Flexible PCB (16) | US $30+ | 100% | ≤5h | - | 1 pc | $0.10–8.00 |

| Guangzhou Highleap Electronic Co., Ltd. | Guangzhou, CN | PCBA (541), Rigid-Flex PCB (331) | US $280,000+ | 94% | ≤2h | 31% | 1 pc | $0.50–5.00 |

Performance Analysis

Guangdong Global Well and Huizhou Linghangda report perfect on-time delivery records, indicating strong production planning and logistics execution. Suzhou Engine and Guangzhou Highleap stand out for low MOQs (1 piece) and fast response times (≤3h), making them ideal for agile development cycles. Guangzhou Highleap’s extensive product portfolio and high online revenue suggest robust export experience and market demand. Reorder rates above 30%—noted at Global Well and Highleap—signal customer satisfaction despite competitive pricing. Suppliers offering sub-$0.50 unit pricing typically leverage economies of scale and standardized designs, while higher-priced options may include value-added services like firmware programming or enclosure integration.

FAQs

How to verify a keyboard PCB maker's technical capability?

Request sample Gerber files, BOMs, and assembly drawings to evaluate design accuracy. Confirm support for key features such as diode routing, MCU integration (e.g., ATmega32U4), and USB-C connectivity. Video audits of SMT lines and QC stations provide insight into process maturity.

What is the typical lead time for custom keyboard PCBs?

Prototype lead times average 7–10 days, including fabrication and assembly. Mass production (5,000+ units) typically takes 20–30 days post-design approval. Rush services may reduce timelines by 30% with expedited fees.

Do suppliers support small-batch or individual orders?

Yes, multiple suppliers offer MOQs of 1 piece, particularly suited for DIY kits, boutique keyboard brands, or iterative design testing. Unit costs are higher at low volumes but decrease significantly at 1,000+ units.

Are RoHS and REACH compliance standards enforced?

Most suppliers adhere to RoHS compliance for lead-free assembly, especially for EU and North American markets. Explicit confirmation and material declarations should be requested before production begins.

Can I customize layout, silkscreen, and firmware?

Full customization is widely supported, including unique layouts (e.g., 65%, 75%), colored silkscreen, logo printing, and pre-flashed QMK/VIA firmware. Suppliers like Suzhou Engine explicitly list color, size, and packaging as customizable parameters.