Keycap Maker

CN

CN

About keycap maker

Where to Find Keycap Maker Suppliers?

China leads global keycap manufacturing, with specialized production hubs concentrated in Guangdong and Jiangsu provinces. Dongguan and Shenzhen serve as core centers for precision injection molding and customization, hosting vertically integrated facilities capable of end-to-end production—from raw material processing to final packaging. These regions benefit from mature supply chains for PBT, ABS, and thermoplastic resins, enabling rapid prototyping and scalable output.

Suppliers in this ecosystem typically operate dedicated production lines for mechanical keyboard keycaps, supporting both mass production and low-volume custom runs. Average monthly capacities range from 50,000 to over 200,000 units per facility, with advanced capabilities in two-shot injection molding, dye-sublimation, and UV printing. The proximity of component suppliers, tooling workshops, and logistics providers within a 50km radius reduces lead times by up to 30% compared to offshore alternatives. Buyers gain access to flexible MOQs (as low as 1 piece), competitive pricing ($1.59–$16.80/unit), and fast turnaround—typically 7–15 days for standard orders and 20–30 days for fully customized sets.

How to Choose Keycap Maker Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional criteria:

Material & Process Expertise

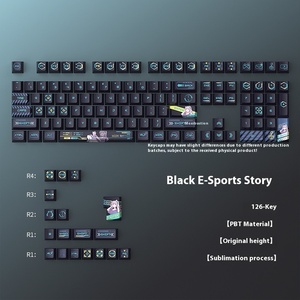

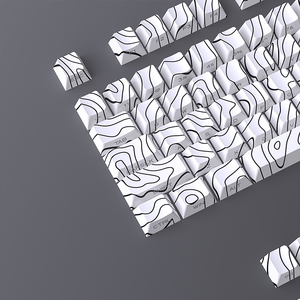

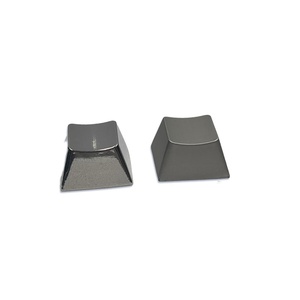

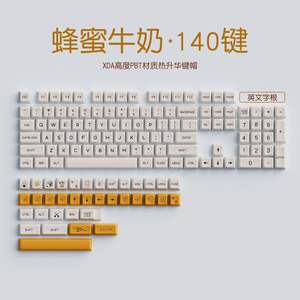

Verify supplier proficiency in primary keycap materials: PBT (preferred for durability and resistance to shine) and ABS (lower cost but prone to wear). Confirm use of two-color injection molding for legends that do not degrade over time. For specialty finishes, assess capabilities in sublimation printing, hand-painting, or CNC machining—particularly relevant for limited-edition or artistic designs.

Production Infrastructure

Evaluate core operational metrics:

- Ownership of in-house injection molding machines (minimum 20 units recommended for scalability)

- Dedicated quality control stations with optical inspection systems

- Customization capacity covering color, font, profile (OEM, Cherry, SA, DSA), and labeling

Cross-reference on-time delivery rates (target ≥98%) and response times (≤2 hours preferred) as indicators of operational efficiency.

Transaction Reliability

Prioritize suppliers with documented quality management practices and verifiable transaction histories. Analyze reorder rates as a proxy for customer satisfaction—rates above 20% suggest consistent product quality and service reliability. Use secure payment methods with escrow protection, especially for initial orders. Request physical samples to validate dimensional accuracy, surface finish, and compatibility with common switch types (Cherry MX, Gateron, Kailh).

What Are the Best Keycap Maker Suppliers?

| Company Name | Location | Online Revenue | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Dongguan Jishiyu Technology Co., Ltd. | Guangdong, CN | US $10,000+ | Keycaps, Keyboard Switches, Gaming Keyboards | 97% | ≤2h | <15% | Color, Material, Design | 1 box / 10 bags |

| Dongguan Shuanglin Injection Molding Co., Ltd. | Guangdong, CN | US $700+ | Keycaps, Computer Accessories | 100% | ≤1h | <15% | Limited (Theme-based) | 1 piece |

| Nanjing Xinzhi Zongyuan Electronic Technology Co., LTD | Jiangsu, CN | US $60,000+ | Custom PBT Keycaps, Labels, Packaging | 100% | ≤7h | 21% | Color, Material, Size, Logo, Graphic | 1 piece / 10 pieces |

| Shenzhen Deying E-Commerce Limited | Guangdong, CN | US $1,900,000+ | Custom Keycaps, OEM Arabic Keycaps, Blank Sets | 98% | ≤7h | 17% | Color, Material, Logo, Label, Graphic | 10–500 pieces (varies by product) |

| Shenzhen Cmany Electronic Technology Co., Ltd. | Guangdong, CN | US $10,000+ | Plastic & Metal Keycaps, Sublimation Transfers, Repair Parts | 100% | ≤2h | 22% | High-Precision CNC, DIY Sublimation, Alloy Materials | 1–500 pieces |

Performance Analysis

Dongguan- and Shenzhen-based suppliers dominate responsiveness and delivery reliability, with three out of five achieving 100% on-time fulfillment. Shenzhen Deying stands out with the highest reported online revenue (US $1.9M+), indicating strong market penetration and export experience. Nanjing Xinzhi Zongyuan and Shenzhen Cmany demonstrate higher reorder rates (21–22%), reflecting superior customer retention likely driven by consistent quality and design flexibility. Suppliers offering two-shot PBT molding and sublimation services command premium pricing ($5.50–$16.80/unit) but deliver longer-lasting products suitable for gaming and professional keyboards. For bulk orders, verify tooling costs and mold amortization terms—some suppliers offer free molds for orders exceeding 1,000 units.

FAQs

How to verify keycap maker supplier reliability?

Assess on-time delivery performance, reorder rate, and response time through supplier dashboards. Request material data sheets (MDS) for PBT/ABS resins and inspect sample batches for shrinkage, warping, and legend alignment. Conduct virtual factory audits to confirm ownership of injection molding equipment and QC processes.

What is the average sampling timeline for custom keycaps?

Standard samples take 5–10 days for existing molds. Custom tooling adds 10–15 days for mold creation. Expect additional time for multi-layer printing or hand-applied finishes. Air shipping adds 3–7 days internationally.

Can keycap suppliers handle global shipping?

Yes, most suppliers support international logistics via express carriers (DHL, FedEx) or sea freight for bulk orders. Confirm Incoterms (FOB, CIF) and ensure compliance with import regulations for plastic goods in destination markets.

Do manufacturers provide free samples?

Policies vary. Some suppliers offer one free sample per design when future orders are guaranteed. Others charge a nominal fee (often refundable against first order). Molded prototypes may incur setup fees unless volume commitments are met.

How to initiate customization requests?

Submit detailed specifications including key profile (e.g., SA, DSA, OEM), material (PBT preferred), color codes (Pantone or RAL), legend type (dye-sublimated, double-shot), and packaging requirements. Reputable suppliers will provide 3D renderings or proof-of-concept samples within 7–10 days.