Tiny Keycap Maker

About tiny keycap maker

Where to Find Tiny Keycap Maker Suppliers?

China remains the global epicenter for precision keycap manufacturing, with leading suppliers concentrated in Guangdong and Zhejiang provinces. Dongguan and Shenzhen serve as primary hubs for mechanical keyboard component production, hosting vertically integrated facilities that specialize in injection molding, dye-sublimation printing, and artisan resin casting. These regions benefit from mature supply chains for PBT (polybutylene terephthalate), ABS (acrylonitrile butadiene styrene), and aluminum alloys—materials critical to durability and tactile performance in compact keycap sets.

The industrial ecosystem enables rapid prototyping and scalable output, with some manufacturers reporting monthly capacities exceeding 500,000 units. Proximity to ports in Shenzhen and Ningbo facilitates efficient export logistics, reducing time-to-market for international buyers. Suppliers leverage localized access to CNC machining services, mold fabrication, and surface treatment technologies, allowing integration of complex geometries such as XDA, SA, or OEM profiles in miniature formats. This infrastructure supports both high-volume OEM orders and low-MOQ custom runs, making the region ideal for niche mechanical keyboard brands and DIY accessory vendors.

How to Choose Tiny Keycap Maker Suppliers?

Procurement decisions should be guided by objective evaluation criteria focused on technical capability, quality consistency, and transactional reliability.

Material & Process Expertise

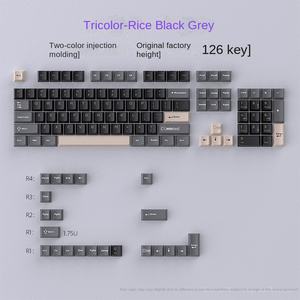

Verify supplier experience with keycap-specific materials: PBT (preferred for wear resistance), double-shot ABS (for legend longevity), and UV-resistant resins (used in artisan keycaps). Confirm use of precision injection molding with tolerances ≤±0.1mm to ensure switch compatibility (Cherry MX, Kailh, Gateron). For customized designs, assess capabilities in dye-sublimation, pad printing, or hand-painting workflows.

Production Capacity Verification

Evaluate operational scale through measurable indicators:

- Minimum factory area of 1,000m² for dedicated molding and finishing lines

- In-house mold design and maintenance teams to reduce lead times

- Monthly output capacity exceeding 100,000 pieces per production line

Cross-reference online revenue metrics and reorder rates to validate order fulfillment stability.

Quality Assurance Protocols

Prioritize suppliers with documented QC processes including first-article inspection, batch sampling (AQL 1.0–2.5), and packaging integrity checks. While formal ISO 9001 certification is not universally listed, consistent on-time delivery (>97%) and response times under 3 hours indicate operational discipline. For resin-based or metal keycaps, verify post-processing steps such as polishing, anodizing, or epoxy coating are performed in controlled environments.

What Are the Best Tiny Keycap Maker Suppliers?

| Company Name | Location | Main Materials | MOQ Range | Unit Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Dongguan City Qianxi Precision Hardware Products Co., Ltd. | Guangdong, CN | PBT, Aluminum | 100 sets | $6.42–8.78 | 42% | ≤11h | 40% | $4,000+ |

| Zhejiang Yunjiang High Tech Co., Ltd. | Zhejiang, CN | Resin, Custom Composites | 1 piece | $0.50–4.90 | 100% | ≤2h | 45% | $60,000+ |

| Shenzhen Tairuixin Precision Mold Co., Ltd. | Shenzhen, CN | PBT, Resin, Metal | 100 pieces | $0.31–15.00 | 100% | ≤3h | <15% | $50,000+ |

| Shenzhen Yiqi Network Technology Co., Ltd. | Shenzhen, CN | PBT, Dye-Sublimated ABS | 10 pieces | $0.15–11.99 | 100% | ≤9h | 100% | $2,300,000+ |

| Dongguan Jishiyu Technology Co., Ltd. | Guangdong, CN | PBT, Thermal Sublimation | 1 piece | $3.90–16.90 | 97% | ≤2h | <15% | $20,000+ |

Performance Analysis

Shenzhen Yiqi Network Technology stands out with a 100% reorder rate and multi-million-dollar annual online revenue, indicating strong market trust and repeat business—likely driven by flexible MOQs and competitive pricing for PBT sets. Zhejiang Yunjiang and Dongguan Jishiyu offer ultra-responsive service (≤2h average response) and single-piece sampling, ideal for designers testing new concepts. Shenzhen Tairuixin provides broad material versatility, supporting metal and artisan resin production at scale. However, lower reorder rates among some high-output suppliers suggest potential gaps in after-sales support or consistency. Buyers seeking reliable long-term partnerships should prioritize suppliers with balanced metrics across delivery performance, responsiveness, and customer retention.

FAQs

How to verify tiny keycap maker reliability?

Review documented quality control procedures, request product samples to assess material finish and dimensional accuracy, and confirm alignment with specified profiles (e.g., XDA, SA). Analyze transaction history, focusing on sustained on-time delivery rates above 97% and verifiable customer feedback on customization fidelity.

What is the typical lead time for custom keycap production?

Standard lead times range from 15 to 25 days after artwork approval and sample confirmation. Complex molds or handcrafted resin variants may extend timelines to 35 days. Air shipping adds 5–7 days for international delivery.

Can suppliers accommodate small-batch custom orders?

Yes, multiple suppliers offer MOQs as low as 10 pieces or even single-unit samples. This flexibility supports prototyping, limited-edition releases, and NFT-linked merchandise development without inventory overcommitment.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers include one-off samples with future order credits, while others charge nominal fees (typically $0.50–$5.00/unit) to cover material and labor. Full-set samples may require partial prepayment, refundable against bulk orders.

How to initiate a custom keycap design project?

Submit detailed specifications including base material, profile type, color codes (Pantone or RAL), engraving depth, and packaging requirements. Reputable suppliers will generate 3D mockups within 48 hours and deliver physical prototypes within 10–14 days for approval.