Label Maker For Food Containers

Top sponsor listing

Top sponsor listing

About label maker for food containers

Where to Find Label Maker for Food Containers Suppliers?

China remains the dominant manufacturing hub for labeling equipment, with key industrial clusters in Fujian and Guangdong provinces driving innovation and scale in food container labeling solutions. Fujian-based suppliers leverage regional expertise in precision printing and packaging materials, enabling integrated production of label applicators with custom graphic outputs. Meanwhile, Dongguan and Shenzhen in Guangdong host concentrated machinery ecosystems specializing in semi-automatic and automatic labeling systems, benefiting from proximity to component suppliers for motors, sensors, and dispensing mechanisms.

These regions support vertically integrated manufacturing models, where design, machining, assembly, and testing occur within consolidated facilities. This integration reduces lead times for standard units to 15–25 days and enables rapid prototyping for customized configurations. Buyers benefit from localized supply chains that reduce material costs by 15–25% compared to offshore alternatives, while maintaining compliance with international food safety standards for material contact surfaces. The presence of mature export logistics networks ensures reliable global delivery via air or sea freight, with FOB terms commonly offered.

How to Choose Label Maker for Food Containers Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compatibility, operational reliability, and transaction security.

Technical & Functional Compliance

Verify that machines are constructed with food-grade stainless steel or corrosion-resistant polymers for hygienic operation. For automated systems, confirm compatibility with common label materials (PET, BOPP, paper) and container types (glass, PET, HDPE). Suppliers should provide documentation on motor durability, sensor accuracy, and labeling speed (typically 20–60 containers per minute for benchtop models). While explicit certifications such as CE or ISO 9001 are not uniformly listed, prioritize suppliers demonstrating consistent quality metrics.

Production and Customization Capability

Assess supplier capacity through key indicators:

- Minimum factory area exceeding 2,000m² for stable output

- In-house engineering teams supporting size, voltage, and labeling pattern customization

- Flexible configuration options for label width (20–150mm), diameter compatibility (30–120mm), and power supply (110V/220V)

- Ability to integrate logo, color, and packaging design services for branded labeling workflows

Cross-reference product listings with on-time delivery rates above 95% to validate operational consistency.

Transaction and Quality Assurance

Utilize secure payment methods with milestone-based disbursements. Request sample units to evaluate build quality, labeling precision, and ease of adjustment before bulk ordering. Confirm post-sale support availability, particularly for mechanical troubleshooting and spare part supply. Analyze reorder rates and response times as proxies for customer satisfaction—suppliers with sub-2-hour response times demonstrate higher service engagement.

What Are the Best Label Maker for Food Containers Suppliers?

| Company Name | Location | Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Key Features |

|---|---|---|---|---|---|---|---|---|

| Fujian Hongye Technology Co., Ltd. | Fujian, CN | Custom Manufacturer | US $20,000+ | 100% | ≤1h | 23% | Multiple SKUs | Graphic, color, size, packaging customization; main focus on labels and paperboard printing |

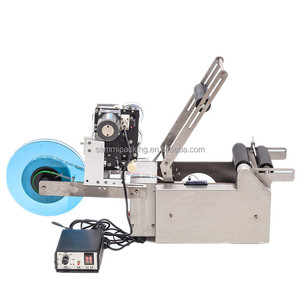

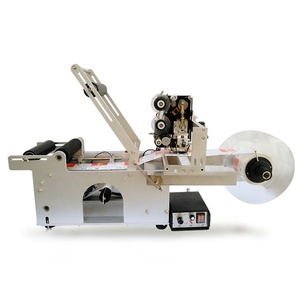

| Dongguan Sammi Packing Machine Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $380,000+ | 87% | ≤2h | <15% | 5+ models | Adjustable labeling width, diameter, material; semi-auto and desktop variants |

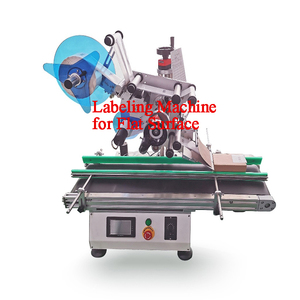

| Dongguan BanMo Machinery Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $390,000+ | 99% | ≤2h | <15% | 5+ models | Manual and automatic options; PET, jar, flat-surface labeling; price range $55–$1,899 |

| Dongguan Haixingda Machinery Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $280,000+ | 99% | ≤2h | <15% | 5+ models | Flat, round, semi-auto labeling; wide price spread ($49.90–$2,499); customization supported |

| Shenzhen Yichengxing Electronic Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $7,000+ | 100% | ≤4h | <15% | 5+ manual units | Hand-operated can and bottle labelers; compact design; pricing from $129–$230 |

Performance Analysis

Fujian Hongye Technology stands out as a dedicated custom manufacturer with 100% on-time delivery and rapid ≤1-hour response times, ideal for buyers requiring integrated label design and production. Dongguan-based suppliers—Sammi, BanMo, and Haixingda—collectively represent high-capacity manufacturers with combined online revenues exceeding US $1 million, offering diverse machine types from manual dispensers to fully automatic systems. Despite lower reorder rates (<15%), their 99% on-time performance indicates strong fulfillment discipline. BanMo and Haixingda provide cost-effective entry-level options starting under $50, suitable for small-scale food producers. Shenzhen Yichengxing, while smaller in revenue, maintains perfect delivery records and specializes in ergonomic hand-held labelers for low-volume applications.

FAQs

What is the typical MOQ for label makers used in food container labeling?

Most suppliers set a minimum order quantity of 1 unit, allowing buyers to purchase single machines for testing or small operations. Bulk pricing typically applies at 5+ units, with discounts varying by model complexity and automation level.

How long does it take to receive a sample or initial order?

Sample processing takes 7–14 days for standard models. Customized units require 15–25 days depending on modifications. Shipping via express courier takes 5–7 days internationally; sea freight adds 25–35 days but reduces logistics costs for container-sized shipments.

Can label makers be customized for specific container shapes?

Yes, most suppliers offer adjustments for round, flat, oval, and tapered containers. Custom tooling may be required for irregular geometries, which should be validated through pre-production samples. Manual and semi-automatic models are more adaptable to variable sizes than fixed-rail automatic systems.

Do suppliers support private labeling and OEM branding?

Many suppliers, particularly Fujian Hongye and Dongguan-based manufacturers, offer OEM services including custom color schemes, logo imprinting, user interface labeling, and branded packaging—enabling direct integration into private-label production lines.

What materials are compatible with these label makers?

Machines support adhesive labels made from paper, PET, PVC, and BOPP films. Compatibility depends on label thickness (0.05–0.2mm typical) and backing type. Suppliers often provide material recommendations based on environmental conditions such as moisture, temperature, and UV exposure in food storage environments.