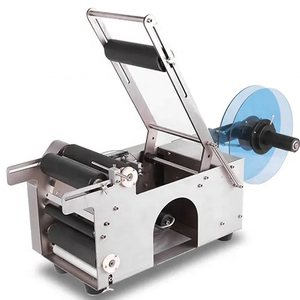

Label Maker For Jars And Bottles

About label maker for jars and bottles

Where to Find Label Maker for Jars and Bottles Suppliers?

China remains the global epicenter for labeling machinery production, with key manufacturing clusters in Guangdong and Shandong provinces driving innovation and cost efficiency. Dongguan, located in Guangdong, hosts a dense network of precision engineering firms specializing in compact, high-speed labeling systems for small to mid-sized containers. This region benefits from proximity to polymers, adhesives, and electronics suppliers, reducing component lead times by 20–30% compared to offshore alternatives.

Shandong’s Jining zone focuses on industrial-grade equipment, integrating robust stainless steel frames and servo-driven automation for continuous operation. These clusters support vertically integrated production—encompassing CNC machining, control system assembly, and final testing—within tightly coordinated supply ecosystems. Buyers gain access to scalable output, with standard machine delivery typically within 15–30 days. Cost advantages range from 25–40% over European or North American manufacturers, particularly for semi-automatic and desktop models tailored to food, beverage, and cosmetic packaging lines.

How to Choose Label Maker for Jars and Bottles Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm adherence to international safety and performance benchmarks. CE marking is essential for market access in Europe, while UL/CSA compliance supports deployment in North America. Request documentation on motor efficiency (typically 750W–1.5kW), labeling accuracy (±0.5mm tolerance), and compatibility with container materials (glass, PET, HDPE). Verify sensor types—optical or fiber-optic—for precise label placement on curved or irregular surfaces.

Production Capacity & Infrastructure

Assess supplier capability through measurable indicators:

- Facility size exceeding 2,000m² indicating dedicated production lines

- In-house engineering teams capable of customizing conveyor widths, bottle diameters (20–120mm typical), and integration with filling or capping systems

- Monthly output capacity of 50–200 units per model, ensuring scalability

- On-time delivery rate above 97%, validated through historical transaction data

Customization & Quality Assurance

Leading suppliers offer configurable options including label roll size (max 600mm diameter), print head integration (thermal transfer or inkjet), and language-specific HMI panels. Prioritize vendors providing pre-shipment testing reports, including dry-run videos and calibration certificates. Reorder rates below 15% may indicate limited customer retention, whereas response times under 2 hours reflect strong service commitment.

Procurement Safeguards

Utilize secure payment frameworks such as escrow services to align payment milestones with delivery and inspection. Conduct factory audits via video tour to validate claims about automation level and quality control processes. Always request physical samples to evaluate labeling consistency, adhesive feed mechanism, and noise levels (typically 60–75 dB) before scaling orders.

What Are the Best Label Maker for Jars and Bottles Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Jining Keepway Machinery Company Ltd. | Shandong, CN | Labeling Machines, Wrapping Machines, Multi-Function Packaging Systems | US $610,000+ | 97% | ≤2h | 34% | Automatic round bottle, wine, aluminum can labeling | $940.50 – $4,600 |

| Dongguan BanMo Machinery Co., Ltd. | Guangdong, CN | Semi-Automatic Applicators, Manual Dispensers, Bench-Top Labellers | US $380,000+ | 99% | ≤2h | <15% | Desktop semi-automatic, pet jar, water bottle labeling | $55 – $969 |

| Dongguan Migada Machinery Co.,Ltd. | Guangdong, CN | Automatic Tabletop, Stainless Steel Can, Film Labeling Machines | US $90,000+ | 100% | ≤1h | <15% | Small bottle, vial, ampoule, plastic container labeling | $176 – $2,229 |

| Dongguan Haixingda Machinery Co., Ltd. | Guangdong, CN | Flat & Round Bottle Applicators, PVC Manual Labelers | US $270,000+ | 99% | ≤2h | <15% | Full-auto desktop, self-adhesive, manual PVC labeling | $170 – $2,800 |

| Shanghai Gebo Machinery Co., Ltd. | Shanghai, CN | Semi-Automatic Applicators, Pneumatic Labelers, Date Printers | US $40,000+ | 94% | ≤2h | <15% | Retail-scale metal, plastic, round bottle labeling | $275 – $650 |

Performance Analysis

Jining Keepway stands out with the highest reorder rate (34%) and broadest product range, including high-capacity automatic systems priced up to $4,600, suitable for large-scale bottling operations. Dongguan-based suppliers dominate responsiveness and customization agility, with BanMo offering entry-level bench-top units at $55, ideal for startups or pilot lines. Migada achieves perfect on-time delivery (100%) and sub-hour response times, signaling strong internal coordination despite lower customer repeat rates. Haixingda provides mid-tier automated solutions with competitive pricing, while Shanghai Gebo serves niche markets with pneumatic and date-stamping integrated models. Buyers seeking turnkey integration should prioritize suppliers offering CAD layout support and PLC programming logs.

FAQs

How to verify label maker supplier reliability?

Cross-validate certifications (CE, ISO 9001) with issuing bodies and request test reports on labeling speed (up to 60 bottles/min for automatic models), motor lifespan, and electrical safety. Analyze transaction history for consistent order fulfillment and review customer feedback focused on after-sales technical support and spare parts availability.

What is the average lead time for label makers?

Standard units ship within 15–25 days after order confirmation. Custom configurations involving non-standard conveyor lengths or dual-side labeling extend timelines to 35–45 days. Air freight delivers samples in 7–10 days; sea freight takes 25–35 days depending on destination port.

Do suppliers offer customization for specific bottle shapes?

Yes, most suppliers provide adjustments for diameter (20–120mm), height (50–350mm), and curvature. Custom tooling for square jars, oval bottles, or tapered containers is available upon submission of CAD drawings or physical samples. Minimum order quantities for customized units typically start at 5 sets.

Are free samples available?

Sample policies vary. Some suppliers offer functional demos at reduced cost ($50–$200), refundable against future bulk orders. Fully free samples are rare but possible for high-potential buyers committing to minimum annual volumes (e.g., 50+ units).

What are typical MOQ and payment terms?

MOQ is generally 1 set for standard models, facilitating low-risk trials. Payment structures include 30% deposit with balance before shipment, or use of trade assurance programs for dispute protection. Bulk orders (10+ units) often qualify for 5–10% discounts and extended warranty coverage (12–24 months).