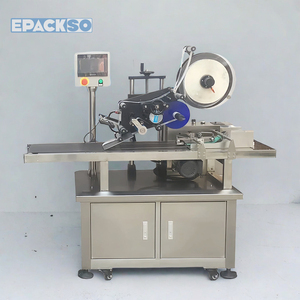

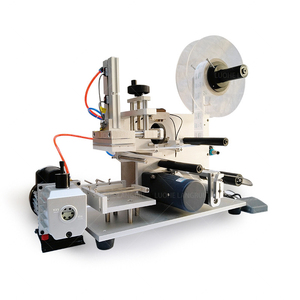

Label Maker For Clothes And Bottles

1/15

1/15

1/29

1/29

About label maker for clothes and bottles

Where to Find Label Maker for Clothes and Bottles Suppliers?

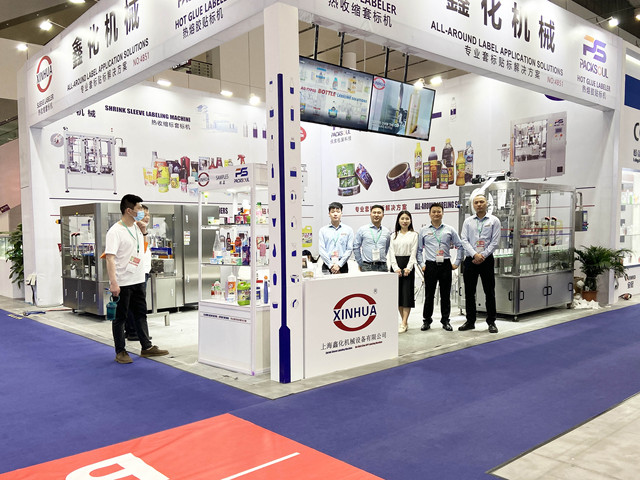

China remains the global hub for labeling machinery production, with key manufacturing clusters in Guangdong and Henan provinces driving innovation and cost efficiency. Dongguan and Shenzhen in Guangdong host advanced automation facilities specializing in semi-automatic and fully automatic labeling systems for textiles and containers. These regions benefit from integrated supply chains for servo motors, sensors, and stainless-steel components, reducing assembly lead times by 20–30% compared to offshore alternatives.

Henan’s Zhengzhou cluster focuses on mid-range industrial labeling equipment, leveraging localized engineering talent and lower labor costs to offer competitive pricing without compromising core functionality. The proximity of material suppliers and precision machining workshops within 30km enables rapid prototyping and just-in-time component delivery. Buyers gain access to scalable production networks capable of fulfilling orders ranging from single units to container-sized batches, with standard lead times averaging 15–25 days post-deposit.

How to Choose Label Maker for Clothes and Bottles Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Functionality

Confirm compatibility with substrate types: woven fabric tags, polyethylene labels, PET bottles, and glass containers. Machines should support variable label widths (10–120mm typical), diameters (20–100mm for bottles), and materials including UV-resistant, waterproof, or heat-sensitive adhesives. For apparel applications, verify integration capability with tag feeding systems and coding functions (e.g., batch numbers, barcodes).

Production Capability Verification

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area of 1,000m² indicating dedicated production lines

- In-house R&D teams focused on motion control, sensor calibration, and user interface design

- On-site testing protocols for labeling accuracy (±0.5mm tolerance) and cycle durability (≥10,000 cycles)

- Cross-reference online revenue data and reorder rates as proxies for market acceptance

Transaction Risk Mitigation

Prioritize suppliers offering third-party inspection options before shipment. Use secure payment methods that release funds upon confirmation of machine performance at destination. Evaluate responsiveness—sub-4-hour reply times correlate with stronger post-sale support. Request sample outputs or video demonstrations of labeling precision on actual product samples prior to bulk ordering.

What Are the Best Label Maker for Clothes and Bottles Suppliers?

| Company Name | Location | Verification Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Dongguan Auchan Automation Equipment Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $230,000+ | 87% | ≤4h | 20% | Semi-auto round bottle & clothing labelers | Label size, diameter, material, coding, UV compatibility |

| Zhengzhou Miles Tech Company Ltd. | Henan, CN | Multispecialty Supplier | US $1,000,000+ | 93% | ≤3h | <15% | Auto flat-top, handheld, high-precision round labelers | Color, thickness, roll weight, slitting, graphic alignment |

| Shenzhen Especial Tech Co., Ltd. | Guangdong, CN | - | US $10,000+ | 100% | ≤6h | 50% | Automatic poly-bag, flat surface, gift card, plastic bottle | Limited (mainly standard models) |

| Kunshan Yuanhan Electronic Equipment Co., Ltd. | Jiangsu, CN | - | US $10,000+ | 88% | ≤8h | <15% | Clothing tape, ultrasonic woven label, applicator systems | Specialized textile labeling solutions |

| Dongguan Keyida Machinery Co., Ltd. | Guangdong, CN | - | US $210,000+ | 100% | ≤1h | 20% | Manual, semi-auto, double-sided flat & round bottle | Bottle size, labeling width, manual/automatic modes |

Performance Analysis

Dongguan-based suppliers dominate in response speed and customization depth, with Keyida achieving a 100% on-time delivery rate and sub-one-hour average response time. Shenzhen Especial stands out for customer retention (50% reorder rate), suggesting strong product reliability despite limited customization. Zhengzhou Miles leads in transaction volume (over US$1M online revenue), reflecting broad market penetration, though its reorder rate remains below 15%, potentially indicating competitive pressure. For high-mix, low-volume needs—such as boutique apparel brands or specialty beverage producers—prioritize suppliers with proven flexibility in label geometry and material handling. For standardized high-throughput operations, focus on delivery consistency and technical documentation completeness.

FAQs

What is the typical MOQ for label makers?

Most suppliers list a minimum order quantity of 1 set or piece, allowing buyers to procure individual units for testing or small-scale deployment. Bulk discounts generally apply starting at 5+ units, with negotiated pricing available for container-load orders.

How long does it take to receive a sample unit?

Sample processing typically takes 7–14 days after payment confirmation. Shipping via express courier adds 5–8 business days internationally. Some suppliers offer expedited builds (5 days) for validated buyers.

Can these machines handle both clothing tags and bottles?

While some models are designed specifically for either soft goods or rigid containers, multi-functional units exist with interchangeable guides and adjustable tension controls. Confirm dual-application support directly with the manufacturer before procurement.

Do suppliers provide technical documentation and after-sales support?

Leading suppliers offer operation manuals, wiring diagrams, and basic troubleshooting videos. Remote guidance via video call is common during installation. Warranty periods range from 12–24 months, covering core mechanical and electrical components.

Are custom voltage and plug configurations available?

Yes, most manufacturers accommodate 110V/60Hz or 220V/50Hz requirements and can equip machines with EU, UK, or North American power plugs upon request. Customization must be specified prior to production.