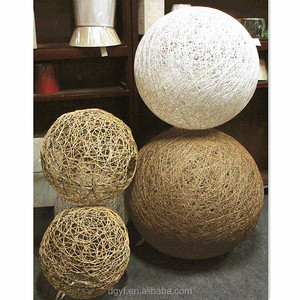

Lamp Shade For Small Lamp

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

CN

CN

1/25

1/25

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

1/3

1/3

1/50

1/50

0

0

1/3

1/3

1/3

1/3

About lamp shade for small lamp

Where to Find Lamp Shade for Small Lamp Suppliers?

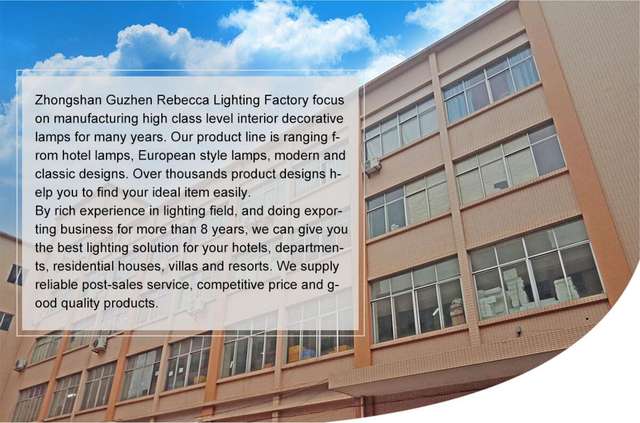

China remains the central hub for lighting component manufacturing, with specialized production clusters in Guangdong and Zhejiang provinces driving efficiency in decorative lighting accessories such as lamp shades for small lamps. The Pearl River Delta region, particularly around Zhongshan City, hosts over 70% of China’s lighting OEMs, benefiting from decades of accumulated expertise in metal fabrication, glass molding, and textile finishing. This concentration enables tightly integrated supply chains where raw materials—from aluminum extrusions to silk fabrics—can be sourced within a 30km radius.

These industrial ecosystems support high levels of customization and rapid prototyping, with many facilities operating automated coating lines and precision stamping equipment capable of producing intricate designs at scale. Buyers typically experience lead times of 25–40 days for bulk orders, depending on material complexity and finishing requirements. Localized logistics networks reduce transportation costs by up to 25%, while vertical integration across plating, welding, and assembly stages ensures consistent quality control. The region also supports low MOQs (as low as 50–100 units) for niche or boutique lighting designs, making it ideal for both mass-market and specialty product lines.

How to Choose Lamp Shade for Small Lamp Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and compliance dimensions:

Material & Process Capability

Confirm supplier proficiency in key materials: spun aluminum, hand-blown glass, fabric composites, or molded polymers. For metal shades, verify access to deep-drawing presses and powder-coating lines. Glass specialists should have annealing ovens and mold calibration systems. Evaluate finishing options—brushed, polished, painted, or etched surfaces—against sample consistency.

Quality Assurance Systems

Prioritize suppliers with documented quality management protocols. ISO 9001 certification indicates standardized inspection routines for dimensional accuracy, color matching, and structural integrity. For EU-bound products, ensure RoHS and REACH compliance, particularly regarding lead content in glass or chemical treatments in textiles. Request batch test reports covering light diffusion uniformity and heat resistance (minimum 60°C sustained exposure).

Customization & Technical Support

Assess design collaboration capacity:

- Minimum 3D CAD modeling support for custom profiles

- In-house tooling workshop for rapid mold adjustments

- Sample turnaround time under 10 working days

Cross-reference prototype fidelity with final production output to validate process stability.

Transaction Reliability

Utilize secure payment frameworks with milestone-based disbursements. Review order history for on-time delivery performance (target ≥95%) and defect rates below 2%. Conduct pre-shipment inspections via third-party auditors to verify packaging durability and labeling accuracy. Retain samples from initial runs for future quality benchmarking.

What Are the Best Lamp Shade for Small Lamp Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

In the absence of verified supplier records, procurement teams should prioritize manufacturers demonstrating proven export experience to North American and European markets. Historical performance indicators—such as reorder rates above 30% and response times under 4 hours—signal strong customer alignment. Facilities exceeding 3,000m² typically maintain dedicated QA departments and automated production zones, reducing variability in finish quality. When evaluating new partners, request video audits of coating lines and stress-testing procedures to confirm adherence to thermal safety standards. High-performing suppliers often provide digital catalogs with photometric data and mounting interface specifications to streamline integration into end-product assemblies.

FAQs

How to verify lamp shade supplier reliability?

Validate certifications through official registries and request audit trails for raw material sourcing. Inspect finished goods for seam uniformity, edge finishing, and symmetry. Analyze feedback from prior buyers focusing on packaging adequacy and consistency across repeat orders.

What is the average sampling timeline?

Standard samples take 7–12 days to produce, including surface treatment and packaging mockups. Custom molds may extend this to 18–22 days. Air shipping adds 5–8 days internationally, depending on destination region.

Can suppliers ship lamp shades worldwide?

Yes, most established exporters offer FOB, CIF, and DDP terms. Confirm packaging meets drop-test standards for fragile components, especially for glass or ceramic variants. Sea freight is recommended for container-sized shipments to minimize breakage risk and optimize cost per unit.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for qualified buyers committing to minimum annual volumes (e.g., 1,000+ units). Otherwise, expect to cover 50–80% of material and labor costs, which may be credited upon order placement.

How to initiate customization requests?

Submit detailed specifications including diameter, height, slope angle, top/bottom rim configuration, and required luminance diffusion. Provide 2D technical drawings or 3D models in STEP or DWG format. Leading suppliers return design proposals within 72 hours and deliver functional prototypes within three weeks.