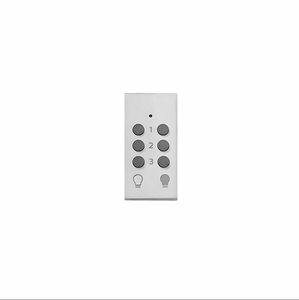

Light Remote Control Producer

1/1

1/1

1/3

1/3

1/19

1/19

1/2

1/2

1/3

1/3

1/3

1/3

0

0

1/24

1/24

1/3

1/3

1/1

1/1

0

0

1/3

1/3

1/1

1/1

1/1

1/1

1/31

1/31

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About light remote control producer

Where to Find Light Remote Control Producers?

China remains the global epicenter for light remote control manufacturing, with concentrated production hubs in Guangdong and Zhejiang provinces. These regions host vertically integrated supply chains specializing in consumer electronics and smart home components, enabling rapid prototyping and high-volume production. Guangdong, particularly around Shenzhen, leverages its advanced electronics ecosystem—home to semiconductor distributors, PCB fabricators, and wireless module developers—allowing producers to source core components within a 20km radius. Zhejiang’s Ningbo and Yiwu zones focus on cost-efficient assembly operations, supported by localized plastic molding and surface-mount technology (SMT) lines.

The industrial clusters support economies of scale, with many facilities capable of monthly outputs exceeding 500,000 units. Localized sourcing of ABS plastics, RF/Wi-Fi modules, and microcontrollers reduces material lead times to 3–7 days, while automated SMT lines ensure consistent soldering precision. Buyers benefit from shorter development cycles (typically 10–14 days from design finalization to pilot run), 15–25% lower unit costs compared to non-Asian manufacturers, and flexibility in both OEM branding and technical customization.

How to Choose Light Remote Control Producers?

Implement structured evaluation criteria to mitigate sourcing risks:

Quality & Compliance Verification

Confirm adherence to international standards including ISO 9001 for quality management and RoHS/REACH compliance for hazardous substance restrictions. For markets requiring electromagnetic compatibility (EMC), verify CE (Europe) or FCC Part 15 (USA) certification documentation. Request test reports for signal stability (e.g., 30m range under interference conditions) and battery leakage resistance under IEC 60086-4 protocols.

Production Infrastructure Assessment

Evaluate key operational benchmarks:

- Minimum 2,000m² factory area with ESD-protected assembly zones

- In-house SMT and injection molding capabilities to reduce third-party dependencies

- Dedicated QA teams conducting 100% functional testing on final units

Cross-reference production capacity claims with verified order history, targeting suppliers maintaining >95% on-time delivery performance.

Sourcing Risk Mitigation

Utilize secure transaction models such as letter of credit or escrow services until product inspection is completed at destination. Prioritize suppliers with documented export experience to your target market, particularly those familiar with import regulations for electronic control devices. Pre-shipment sampling is critical—test at least three units per batch variant for button cycle durability (target: 50,000+ presses) and signal latency (ideally <100ms).

What Are the Best Light Remote Control Producers?

No supplier data available for comparative analysis.

Performance Analysis

In the absence of specific supplier profiles, procurement focus should remain on infrastructure-backed capabilities rather than individual company rankings. Emphasis must be placed on verifying technical compliance, especially for wireless transmission modules operating under regional regulatory frameworks (e.g., 2.4GHz ISM band rules). Given the commoditized nature of basic infrared and RF remotes, differentiation lies in engineering responsiveness, firmware customization ability (for addressable lighting systems), and long-term supply continuity. Buyers are advised to conduct virtual audits and request detailed process flowcharts before engagement.

FAQs

How to verify light remote control producer reliability?

Validate certifications through official databases (e.g., FCC ID search, EU NANDO). Request audit trails covering incoming material inspection, in-process QC checkpoints, and final packaging protocols. Assess after-sales performance via third-party review platforms focusing on defect resolution timelines and replacement fulfillment rates.

What is the average sampling timeline?

Standard sample production takes 7–12 days, depending on whether existing molds or PCB designs are used. Custom enclosures requiring new injection molds extend timelines to 20–25 days. Air shipping adds 5–8 days for international delivery.

Can producers ship globally?

Yes, experienced manufacturers offer full export logistics, including sea and air freight options. Confirm Incoterms (FOB, CIF, DDP) during negotiation and ensure compliance with destination-country electrical safety and radio frequency regulations. Battery-containing shipments require UN38.3 certification and proper Class 9 labeling.

Do manufacturers provide free samples?

Sample policies vary by order intent. Established suppliers may waive fees for qualified buyers committing to MOQ fulfillment. Otherwise, expect to cover material and labor costs, typically ranging from $20–$50 per unit, refundable against future orders.

How to initiate customization requests?

Submit detailed specifications including control protocol (IR, RF 433MHz, Zigbee, Bluetooth), button layout, LED indicators, power requirements (battery type, voltage), and enclosure dimensions. Leading producers provide CAD drawings and firmware configuration options within 48 hours and deliver working prototypes in 2–3 weeks.