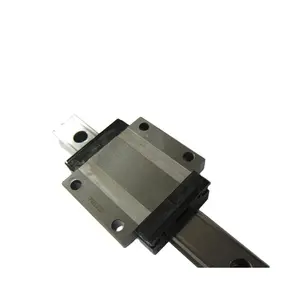

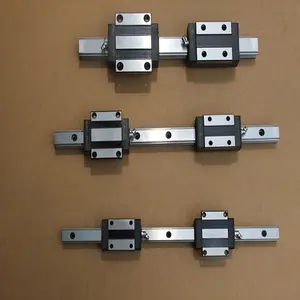

Linear Guide Rail Producer

Top sponsor listing

Top sponsor listing

0

0

1/15

1/15

1/3

1/3

1/20

1/20

1/2

1/2

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/11

1/11

1/25

1/25

1/2

1/2

1/3

1/3

1/3

1/3

1/40

1/40

1/3

1/3

About linear guide rail producer

Where to Find Linear Guide Rail Producers?

China remains the global epicenter for linear guide rail manufacturing, with key industrial hubs concentrated in Zhejiang, Guangdong, and Tianjin. These regions host vertically integrated supply chains combining precision machining, heat treatment, and quality control under one ecosystem. Zhejiang specializes in high-precision components using automated CNC grinding lines, achieving geometric tolerances within ±0.005mm. Dongguan-based producers focus on automation-integrated solutions, aligning output with robotics and semiconductor equipment demand. Tianjin benefits from proximity to northern China’s heavy industry base, supporting large-scale production of load-bearing rails.

The clustering enables rapid component sourcing—raw bearing steel (GCr15/SUJ2), hardened shafts, and recirculating ball systems are available within 50km. This localization reduces lead times by 25–40% compared to offshore alternatives. Buyers gain access to scalable production facilities capable of fulfilling orders from prototype batches to container-sized volumes. Average delivery cycles range from 15–30 days for standard configurations, with customization adding 7–10 days depending on complexity. Cost efficiency is further enhanced through bulk material procurement and energy-optimized processing, yielding 18–28% lower unit costs than European or North American manufacturers.

How to Choose Linear Guide Rail Producers?

Evaluate suppliers using these technical and operational benchmarks:

Quality Management Systems

Confirm adherence to ISO 9001 standards as a baseline for process control. For applications in medical, aerospace, or semiconductor sectors, verify compliance with RoHS and REACH directives. Request test reports on hardness (typically HRC 58–62 for raceways), surface roughness (Ra ≤ 0.2μm), and dynamic load ratings aligned with ISO 14728-1.

Production Infrastructure Assessment

Prioritize manufacturers with in-house capabilities across critical stages:

- Material sourcing from certified steel mills (e.g., GCr15, stainless steel SUS304/316)

- CNC grinding and lapping lines for rail straightness and parallelism control

- Automated assembly and preloading adjustment for carriage blocks

- Dedicated metrology labs equipped with CMMs and laser interferometers

Cross-reference facility scale indicators—such as monthly output capacity and number of active production lines—with on-time delivery performance (target ≥90%) to assess reliability.

Customization and Technical Support

Assess engineering responsiveness: leading suppliers provide CAD models, load simulation data, and mounting interface specifications within 48 hours. Verify support for custom lengths (standard: 100–4000mm), surface treatments (chrome plating, black oxide), accuracy grades (normal, high, precision), and sealing options (metal scrapers, rubber wipers). Reorder rate (ideally >20%) serves as a proxy for product consistency and service satisfaction.

What Are the Leading Linear Guide Rail Producers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Tianjin Ounaida Transmissions Machinery Trading Co., Ltd. | Tianjin, CN | Transmission Chains (434), Rack Gears (275), Linear Guides (120) | 100% | ≤2h | 23% | US $340,000+ | Color, size, logo, packaging, label, graphic |

| Dongguan Xisike Transmission Technology Co., Ltd. | Guangdong, CN | Linear Robots (98), Linear Guides (57), Ball Screws (23) | 92% | ≤1h | 21% | US $50,000+ | Not specified |

| Zhejiang Jiateng Precision Technology Co., Ltd. | Zhejiang, CN | Linear Guides (OEM MGN series), Stainless Steel Variants | 100% | ≤9h | <15% | US $10,000+ | Material, size, rail drawing, length, accuracy, model, packaging |

| Zhejiang Zhishang Robotics Co., Ltd. | Zhejiang, CN | Industrial-Grade Linear Guides, High-Speed Rails | 80% | ≤1h | 25% | US $2,000+ | Material, size, logo, packaging, label, graphic |

| Zhongmin Motor (Shenzhen) Co., Ltd. | Guangdong, CN | Ball Screws (83), Linear Guides (66), Needle Bearings (30) | 100% | ≤3h | - | US $2,000+ | Not specified |

Performance Analysis

Tianjin Ounaida demonstrates strong logistics reliability (100% on-time delivery) and repeat business (23% reorder rate), supported by diversified transmission product offerings. Dongguan Xisike excels in responsiveness (≤1h) and integration with motion systems, positioning it well for automation projects. Zhejiang Jiateng offers deep customization including material and accuracy grading but shows lower customer retention, suggesting potential gaps in post-sale support. Zhejiang Zhishang achieves the highest reorder rate (25%) despite moderate delivery performance, indicating competitive pricing or niche application fit. Zhongmin Motor maintains perfect delivery records and integrates linear guides with complementary motion components, enhancing system-level sourcing efficiency.

FAQs

How to verify linear guide rail producer credibility?

Validate certifications through official registries. Request documentation on raw material traceability, heat treatment processes, and dimensional inspection reports. Analyze transaction history metrics such as response time consistency and dispute resolution outcomes.

What is the typical MOQ and pricing range?

Standard MOQ starts at 1–2 pieces for sample validation. Unit prices vary by type: miniature guides (MGN5–MGN12) range from $2.50–$25; heavy-duty rails (LGH35+) start at $80–$120 per piece. Volume discounts apply beyond 50 units.

Can producers accommodate custom engineering requests?

Yes, most suppliers support tailored lengths, preload classes, corrosion-resistant materials (stainless steel), and non-standard mounting dimensions. Submit technical drawings or 3D models for feasibility assessment. Prototypes typically delivered within 10–14 days.

What are common lead times for bulk orders?

Standard production lead time is 15–25 days after order confirmation. Customized batches require 20–35 days, depending on design complexity and tooling requirements. Expedited processing may reduce timelines by 5–7 days at additional cost.

Do manufacturers offer export-ready packaging and documentation?

Established producers provide seaworthy packaging with anti-corrosion protection and complete shipping documentation, including commercial invoices, packing lists, and material certificates. Confirm HS code classification and destination-specific labeling requirements during order finalization.