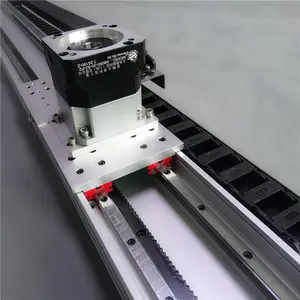

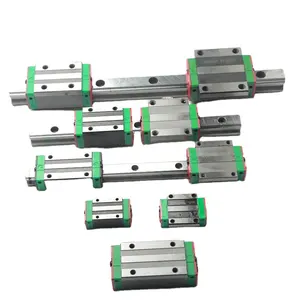

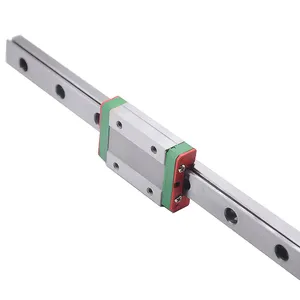

Linear Guideway Rail

1/15

1/15

1/25

1/25

1/11

1/11

1/20

1/20

1/25

1/25

1/11

1/11

1/24

1/24

About linear guideway rail

Where to Find Linear Guideway Rail Suppliers?

China remains the global epicenter for linear guideway rail manufacturing, with specialized industrial hubs in Guangdong, Zhejiang, and Shandong provinces driving production efficiency and export competitiveness. Dongguan and Tianjin serve as key nodes for high-precision linear motion components, supported by mature supply chains for hardened steel, aluminum alloys, and precision grinding infrastructure. These clusters enable vertically integrated production—from raw material processing to final assembly—reducing component lead times by 20–35% compared to decentralized manufacturing models.

The concentration of technical expertise and CNC machining capacity in these regions supports both standard and custom-engineered linear guideways. Suppliers leverage localized access to heat treatment facilities and metrology labs to maintain tight tolerances (down to ±0.01mm), critical for CNC, robotics, and automation applications. Buyers benefit from rapid prototyping capabilities, scalable batch production, and direct integration with international logistics networks, particularly via Shenzhen, Ningbo, and Qingdao ports.

How to Choose Linear Guideway Rail Suppliers?

Procurement decisions should be guided by rigorous evaluation of technical, operational, and transactional performance indicators:

Quality & Compliance Verification

Confirm adherence to international dimensional and performance standards such as ISO 14617 and JIS B 4507. While formal ISO 9001 certification is not explicitly stated in available data, prioritize suppliers demonstrating consistent on-time delivery rates above 98% and verifiable quality control processes. For applications requiring corrosion resistance, validate use of stainless steel or surface treatments like black oxide or electroless nickel plating.

Production & Customization Capacity

Assess supplier capability through the following benchmarks:

- In-house CNC machining and grinding lines for rail straightness and parallelism control

- Minimum order flexibility: MOQs range from 1 piece (individual rails) to 20 pieces (packaged sets)

- Customization options verified across multiple suppliers, including variable rail lengths (e.g., 1M–3M), accuracy grades, engraving, packaging, and color coding

- Dedicated R&D or engineering support indicated by customization tags and responsive communication (target response time ≤3 hours)

Cross-reference product listings with customization claims to confirm actual design-to-delivery workflow maturity.

Transaction Reliability & Risk Mitigation

Prioritize suppliers with documented reorder rates above 45%, indicating customer retention and product reliability. Utilize secure payment mechanisms such as escrow services to align payment milestones with inspection outcomes. Request sample testing to evaluate load capacity, smoothness of motion, and dimensional consistency before scaling orders. Analyze online revenue metrics—suppliers reporting over US $50,000+ annual digital sales typically possess established QC systems and export documentation protocols.

What Are the Best Linear Guideway Rail Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility | Customization Offered |

|---|---|---|---|---|---|---|---|

| Dongguan Xiji Intelligent Technology Co., Ltd. | Linear Robots, Guides, Manipulators | US $10,000+ | 100% | ≤1h | - | 1 piece | No |

| Zhejiang Jiateng Precision Technology Co., Ltd. | Miniature Rails, MGN Series | US $10,000+ | 100% | ≤7h | 17% | 1 piece/set | Yes |

| Dongguan Pinsi Machinery Co., Ltd. | Hiwin-Compatible Guides, Ball Screws | US $50,000+ | 100% | ≤3h | 46% | 1 piece | No |

| Tianjin Haorongshengye Electrical Equipment Co., Ltd. | Round Rails, MGW Series, CNC Components | US $760,000+ | 98% | ≤3h | 50% | 2–20 pieces | Yes |

| Shandong Jingrui Transmission Technology Co., Ltd. | SBR Round Rails, Guide Systems | US $40,000+ | 94% | ≤4h | 29% | 1 meter / 2 pieces | Yes |

Performance Analysis

Dongguan Pinsi and Tianjin Haorongshengye stand out for high reorder rates (46% and 50%, respectively), suggesting strong post-purchase satisfaction and product consistency. Zhejiang Jiateng and Shandong Jingrui offer extensive customization—critical for integrators requiring non-standard lengths, materials, or labeling—with pricing as low as $2.50 per unit for miniature rails. Tianjin-based Haorongshengye leads in digital transaction volume, reflecting robust export readiness and diversified product validation. While most suppliers maintain sub-4-hour response times, Dongguan Xiji achieves the fastest engagement (≤1h), advantageous for urgent sourcing cycles. Buyers seeking OEM-grade compatibility should prioritize suppliers listing Hiwin, MGN, or SBR series equivalents, which indicate reverse-engineering precision and interchangeability testing.

FAQs

How to verify linear guideway rail supplier reliability?

Evaluate on-time delivery history, reorder rate, and response speed as proxies for operational stability. Request material certifications (e.g., GCr15 bearing steel) and dimensional inspection reports. Conduct video audits to confirm in-house machining and quality control stations.

What is the typical lead time for samples?

Standard rail samples are typically shipped within 7–14 days. Custom-cut or engraved rails may require 15–25 days depending on complexity. Air freight adds 5–10 days for international delivery.

Can suppliers provide interchangeable replacements for branded rails?

Yes, multiple suppliers offer dimensionally compliant alternatives to Hiwin, THK, and IKO models (e.g., HGH, MGN, EG series). Verify tolerance class (e.g., C0–C5) and preload specifications to ensure functional equivalence.

Do manufacturers support low-volume or prototype orders?

Most suppliers accept single-piece orders, particularly for standard profiles. However, bulk pricing applies at 20-piece thresholds for certain series. Confirm availability of short-run production before finalizing design commitments.

What are common materials used in linear guideway rails?

High-carbon bearing steel (GCr15/SUJ2) is standard for load-bearing rails, often induction-hardened to 58–62 HRC. Stainless steel variants (e.g., SUS304) are available for corrosive environments. Aluminum housings or lightweight carriages may accompany rail systems for weight reduction.