Heavy Duty Linear Guide Rail

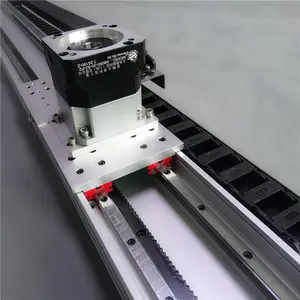

About heavy duty linear guide rail

Where to Find Heavy Duty Linear Guide Rail Suppliers?

China remains the central hub for heavy duty linear guide rail manufacturing, with key production clusters in Zhejiang, Guangdong, and Sichuan provinces. These regions host specialized industrial ecosystems integrating precision machining, material sourcing, and automation component supply chains. Zhejiang excels in high-precision ball and roller guide systems, supported by advanced CNC processing infrastructure and a concentration of R&D-focused engineering firms. Dongguan in Guangdong leverages proximity to robotics and CNC machinery OEMs, enabling rapid prototyping and system integration. Chengdu-based suppliers benefit from regional incentives for intelligent equipment development, facilitating growth in multi-axis modules and motorized stages.

The clustering effect allows suppliers to maintain tight tolerances (±0.01mm) and scalable output through vertically integrated operations—many managing raw material procurement, heat treatment, grinding, and assembly in-house. This integration reduces lead times for standard and custom configurations to 15–30 days. Buyers access cost efficiencies of 20–35% compared to European or North American manufacturers, driven by localized steel and aluminum supply networks and optimized logistics. The ecosystem supports both low-volume sampling and bulk procurement, with modular designs enabling fast reconfiguration for diverse industrial applications including CNC machining centers, gantry robots, and automated material handling systems.

How to Choose Heavy Duty Linear Guide Rail Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

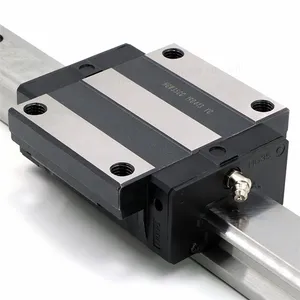

Verify adherence to international standards such as ISO 9001 for quality management. For export markets, confirm compliance with CE or applicable regional safety directives. Request test reports on load capacity, hardness (HRC 58–62 for hardened rails), and surface finish (Ra ≤ 0.4µm). Insist on material certifications for bearing-grade chrome steel (GCr15) or aluminum alloy extrusions where applicable.

Production Capability Verification

Assess core manufacturing competencies:

- In-house CNC grinding and precision milling capabilities to ensure rail straightness and block preload consistency

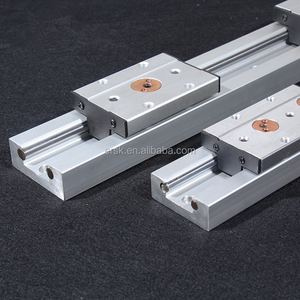

- Capacity for custom lengths (up to 4,000mm reported) and tailored mounting hole patterns

- Integration of ball/roller recirculation systems with dust protection (IP54 or higher)

- Availability of preloaded carriage assemblies and preload adjustment documentation

Cross-reference online revenue metrics and reorder rates as indicators of market acceptance and reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms with milestone-based disbursement. Prioritize suppliers offering sample validation before mass production. Confirm packaging standards to prevent deformation during transit, especially for long-span rails. Evaluate responsiveness (target ≤1 hour) and language proficiency to minimize communication delays in technical coordination.

What Are the Best Heavy Duty Linear Guide Rail Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Zhejiang Weimute Technology Co., Ltd. | Zhejiang, CN | Linear Guides (292), Ball Screws (200) | US $30,000+ | 93% | ≤1h | 20% | Multi-axis modules, motor integration, waterproofing |

| Dongguan Xiji Intelligent Technology Co., Ltd. | Guangdong, CN | Linear Robots (177), Linear Guides (49) | US $10,000+ | 100% | ≤1h | - | Robot rails, rack-and-pinion systems, gantry stages |

| Zhejiang Pheako Machinery Co., Ltd. | Zhejiang, CN | Linear Guides (110), Ball Screws (107) | US $100+ | 100% | ≤1h | <15% | Custom lengths, micro-linear systems, high-precision blocks |

| Chengdu Lian Dong Rui Xin Technology Co., Ltd. | Sichuan, CN | Linear Modules, XYZ Tables | US $120,000+ | 100% | ≤1h | <15% | Motor control, sensor integration, multi-axis accuracy tuning |

| Lishui City Yongrun Precision Machinery Co., Ltd. | Zhejiang, CN | Linear Guides (211), Ball Screws (76) | US $40,000+ | 100% | ≤3h | 15% | Aluminum profiles, TBR-series cylinders, long-span rails |

Performance Analysis

Suppliers like Chengdu Lian Dong Rui Xin demonstrate strong commercial traction with US $120,000+ in verified online revenue, indicating robust order volume and export capability. Zhejiang-based firms dominate product breadth, with Weimute and Yongrun listing over 200 linear guide variants each, reflecting mature production lines and inventory depth. Dongguan Xiji and Pheako achieve perfect on-time delivery records, signaling reliable logistics execution despite lower public reorder metrics. Customization depth varies significantly—Weimute and Chengdu Lian Dong offer comprehensive system-level integration, while Yongrun specializes in cost-effective aluminum and long-length solutions. Buyers seeking drop-in replacements should prioritize high-listing-volume suppliers; those requiring engineered solutions should validate design support through technical documentation and CAD file availability.

FAQs

What are typical MOQ and pricing for heavy duty linear guide rails?

Minimum order quantities typically start at 1 piece or 1 meter, with unit prices ranging from $8.50 to $813 depending on load class, length, and material. Bulk orders (10+ units) often qualify for negotiated pricing. Meter-based pricing is common for continuous rail supply.

How long do lead times usually take?

Standard products ship within 7–15 days. Custom lengths, surface treatments, or integrated motor systems extend lead times to 20–30 days. Expedited processing may be available for urgent orders at additional cost.

Can suppliers provide technical drawings and CAD models?

Yes, most established suppliers offer dimensioned spec sheets, 2D drawings, and 3D STEP files upon request. These include mounting hole spacing, rail height tolerances, and carriage preload specifications critical for integration.

Do heavy duty linear guide rails come pre-lubricated?

Many suppliers apply factory lubrication and seal ends to preserve grease during shipping. However, relubrication before installation is recommended, especially for long-term storage. Some offer sealed-for-life options with maintenance-free polymers.

What customization options are commonly available?

Available modifications include non-standard lengths (up to 4,000mm), special hardening treatments, anti-corrosion coatings, integrated limit switches, and pairing with compatible ball screws or drive systems. Labeling and packaging can also be branded per buyer requirements.