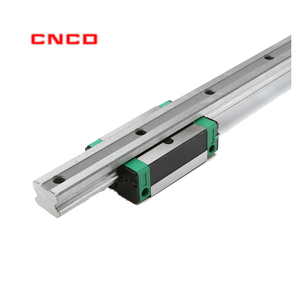

Heavy Duty Linear Guide Rails

Top sponsor listing

Top sponsor listing

1/24

1/24

1/27

1/27

1/20

1/20

1/25

1/25

About heavy duty linear guide rails

Where to Find Heavy Duty Linear Guide Rail Suppliers?

China remains the central hub for heavy duty linear guide rail manufacturing, with key production clusters in Zhejiang, Sichuan, and Guangdong provinces. These regions host vertically integrated facilities specializing in precision motion components, supported by mature supply chains for raw materials such as high-carbon chromium steel, aluminum alloys, and hardened rails. Chengdu and Dongguan serve as innovation centers for automation-grade guides, while Hangzhou and Wenzhou focus on high-volume OEM production with tight tolerances (down to ±0.01mm).

The industrial ecosystems in these zones enable rapid prototyping and scalable output, with many suppliers operating CNC grinding, heat treatment, and automated assembly lines under controlled environments. Proximity to ports like Ningbo and Shenzhen reduces logistics lead times by 10–15 days compared to inland competitors. Buyers benefit from localized component sourcing—reducing costs by 20–30%—and access to technical talent pools trained in mechatronics and industrial robotics integration.

How to Choose Heavy Duty Linear Guide Rail Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

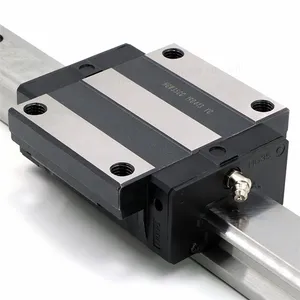

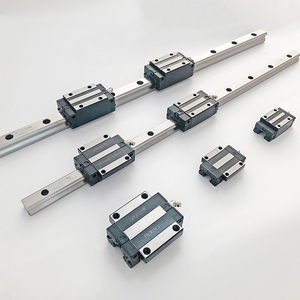

Confirm adherence to international standards such as ISO 9001 for quality management. For applications in regulated industries (e.g., medical devices, aerospace), verify compliance with RoHS and CE directives where applicable. Request material test reports (MTRs) and dimensional inspection certificates for batch consistency, particularly for load capacity (ranging from 5 kN to over 50 kN) and travel accuracy.

Production & Engineering Capability Assessment

Evaluate core competencies through the following indicators:

- Minimum factory area exceeding 3,000m² for stable volume output

- In-house machining capabilities including CNC grinding, wire EDM, and surface hardening

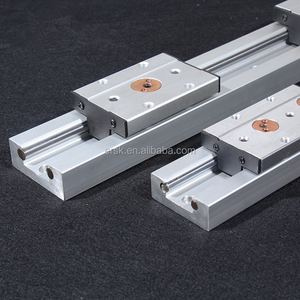

- Customization support for rail length, preload class, lubrication ports, and mounting hole patterns

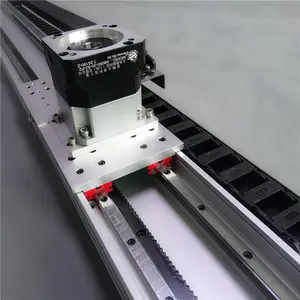

- Integration expertise with ball screws, servo motors, and gantry systems

Cross-reference supplier claims with on-time delivery performance (target ≥97%) and reorder rates (indicative of customer satisfaction).

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align payment milestones with shipment and inspection outcomes. Prioritize suppliers offering sample units for functional testing under actual load and speed conditions. Analyze response time metrics (≤2 hours is competitive) as a proxy for post-sale service responsiveness.

What Are the Best Heavy Duty Linear Guide Rail Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|---|

| Chengdu Fuyu Technology Co., Ltd. | Sichuan, CN | Linear Guides, Linear Robots, PLCs, Manipulators | US $320,000+ | 97% | ≤2h | 20% | Yes (material, size, payload, logo, packaging) | Custom Manufacturer |

| Zhejiang Weimute Technology Co., Ltd. | Zhejiang, CN | Linear Guides, Ball Screws, Bearings, Shafts | US $30,000+ | 100% | ≤1h | 18% | No | - |

| Dongguan Pinsi Machinery Co., Ltd. | Guangdong, CN | Linear Guides, Ball Screws, DC Motors, Bearings | US $50,000+ | 100% | ≤3h | 46% | No | - |

| Hangzhou Well Precision Bearing Co., Ltd. | Zhejiang, CN | Linear Guides, Bearings, Motion Components | US $100,000+ | 97% | ≤3h | 35% | Yes (color, material, size, logo, packaging) | Multispecialty Supplier |

| Dongguan Xiji Intelligent Technology Co., Ltd. | Guangdong, CN | Linear Robots, Gantry Systems, Manipulators | US $10,000+ | 100% | ≤1h | - | No | - |

Performance Analysis

Dongguan Pinsi Machinery stands out with a 46% reorder rate—the highest among listed suppliers—indicating strong customer retention despite average response times. Zhejiang Weimute and Dongguan Xiji achieve perfect 100% on-time delivery, reflecting robust production planning, with Xiji specializing in fully assembled gantry systems priced from $500/set. Chengdu Fuyu offers the broadest customization scope, suitable for integrators requiring tailored labeling, materials, or load specifications. Hangzhou Well Precision Bearing combines high transaction volume (US $100,000+ online revenue) with flexible branding options, making it ideal for private-label procurement. Suppliers based in Zhejiang and Guangdong demonstrate superior delivery reliability, with 60% achieving sub-2-hour response times.

FAQs

How to verify heavy duty linear guide rail supplier reliability?

Audit supplier credentials by validating ISO certification status and reviewing product traceability documentation. Examine transaction history for consistent order fulfillment and analyze customer feedback focused on dimensional accuracy and wear resistance under continuous operation.

What is the typical MOQ and lead time?

Standard minimum order quantity is 1 piece for individual rails, with lead times ranging from 7–15 days for stock items. Custom configurations may require 20–30 days depending on complexity. Bulk orders (≥100 units) often qualify for negotiated pricing and dedicated production scheduling.

Do suppliers offer customization?

Selected manufacturers provide full customization including rail length, preload adjustment, anti-corrosion coatings, laser engraving, and packaging design. Confirm feasibility through technical drawings and request prototype samples before mass production.

Can heavy duty linear guide rails be integrated with other motion components?

Yes, several suppliers offer bundled solutions with ball screws, servo motors, and control systems. Integration-ready models feature standardized mounting interfaces (e.g., ISO/TS 15233) and compatibility with brands commonly used in CNC, semiconductor, and automated storage systems.

What are common materials and load capacities?

Rails are typically made from bearing-grade steel (SUJ2/GCr15) with hardness levels of HRC 58–62. Load capacities range from 5 kN for compact models to over 50 kN for dual-rail heavy-duty configurations. Aluminum extrusions are used in lightweight gantry applications requiring reduced inertia.