Linear Vibration Machine

About linear vibration machine

Where to Find Linear Vibration Machine Suppliers?

China remains the global hub for linear vibration machine manufacturing, with key production clusters concentrated in Henan Province. This region hosts a dense network of specialized electromechanical and material handling equipment manufacturers, particularly in Xinxiang and Luohe, where industrial ecosystems support end-to-end production—from motor integration to screen mesh fabrication. These clusters benefit from established supply chains for vibratory motors, stainless steel frames, and sieve components, enabling cost efficiencies of 20–35% compared to equivalent machinery produced in Europe or North America.

The proximity of component suppliers, welding workshops, and logistics providers within 50 km reduces assembly lead times and enhances scalability. Facilities in this region typically operate automated cutting and bending lines, CNC machining centers, and powder coating systems, allowing rapid turnaround on both standard and custom configurations. Buyers can expect average production lead times of 15–30 days for single units and 30–45 days for bulk orders, depending on customization complexity.

How to Choose Linear Vibration Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to international quality standards such as ISO 9001. For export markets, CE certification is essential for compliance with European safety and electromagnetic compatibility directives. Request documentation on motor performance testing, structural load validation, and material corrosion resistance—particularly for food-grade or mining applications requiring stainless steel (SUS304/SUS316) construction.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house capabilities in laser cutting, robotic welding, and dynamic balancing tests

- Dedicated R&D or engineering teams supporting customization

Cross-reference online revenue indicators and order fulfillment rates: suppliers with verified on-time delivery ≥99% and response times ≤1 hour demonstrate stronger operational reliability.

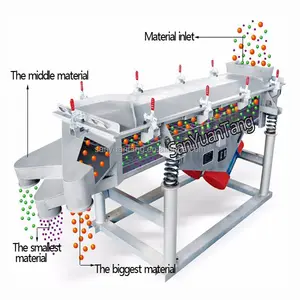

Customization & Transaction Security

Confirm available customization options including sieve layer count (1–5 decks), mesh size (ranging from 20 to 400 mesh), drive motor type (single/dual vibrator), and frame material. Use secure payment mechanisms such as escrow services and insist on pre-shipment inspection rights. Prioritize suppliers offering sample units for performance validation under real-world conditions.

What Are the Best Linear Vibration Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range (Linear Vibration Machines) | Avg. Price Range (USD) | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Luohe Xingdian Electromechanical Equipment Co., Ltd. | Luohe, Henan, CN | US $640,000+ | 99% | ≤1h | <15% | 5 models | $295–$860 | Limited |

| Xinxiang Zhongchengyou Machinery Co., Ltd. | Xinxiang, Henan, CN | US $20,000+ | Not specified | ≤3h | <15% | 5 models | $850–$15,500 | Yes |

| Xinxiang Chengde Energy Technology Equipment Co., Ltd. | Xinxiang, Henan, CN | Not disclosed | 100% | ≤4h | Not specified | 5 models | $1,000–$5,050 | Yes |

| Huzhou Nanxun Shengxiang Grinding Machinery Factory | Huzhou, Zhejiang, CN | US $60,000+ | 100% | ≤1h | <15% | 5 models | $359–$900 | Extensive (mesh, motor, color, layers) |

| Xinxiang Baisheng Machinery Co., Ltd. | Xinxiang, Henan, CN | US $1,000+ | 100% | ≤1h | <15% | 5 models | $1,800–$2,800 | Yes (CE-certified models) |

Performance Analysis

Suppliers like Luohe Xingdian and Huzhou Nanxun offer competitive pricing and fast responsiveness, making them suitable for budget-conscious buyers seeking entry-level machines. Xinxiang-based manufacturers dominate mid-to-high-end segments, providing scalable solutions with robust build quality and customization flexibility. Notably, Xinxiang Baisheng Machinery offers CE-certified heavy-duty models ideal for regulated industries. Despite lower online revenue figures, several suppliers report 100% on-time delivery, indicating strong logistical execution. Buyers should prioritize companies with documented customization workflows and multi-layer screening capabilities for complex separation tasks.

FAQs

How to verify linear vibration machine supplier reliability?

Validate certifications through official registries and request third-party inspection reports. Analyze transaction metrics such as on-time delivery rate, response speed, and customer feedback focused on post-sale support and equipment durability. Conduct virtual factory audits to confirm production processes and quality control checkpoints.

What is the typical minimum order quantity (MOQ)?

Most suppliers list an MOQ of 1 set or piece, facilitating low-volume procurement for testing or niche applications. Bulk pricing typically applies at 5+ units, with potential discounts up to 15% negotiated for container-sized orders.

Are customization options widely available?

Yes, leading suppliers support adjustments in sieve dimensions, mesh count, vibration amplitude, motor power, and frame material. Some offer full OEM branding, including logo printing and custom color schemes. Confirmation of design feasibility should precede order placement.

What are common lead times for production and shipping?

Production lead time ranges from 7–15 days for standard models and 20–35 days for customized units. Air freight delivers samples within 5–10 days globally; sea freight takes 20–40 days depending on destination port and customs procedures.

Do suppliers provide machine testing or samples?

Many offer sample units at full or partial cost, recoverable upon subsequent bulk orders. Pre-shipment testing videos or live demonstrations via video call are commonly provided to validate machine performance before dispatch.