Machine For Block Making

About machine for block making

Where to Find Block Making Machine Suppliers?

China remains the global epicenter for block making machine manufacturing, with concentrated industrial hubs in Shandong and Henan provinces driving innovation and export capacity. Shandong, particularly around Qingdao and Yinan, hosts specialized heavy machinery producers leveraging integrated steel and hydraulic component supply chains, reducing production lead times by up to 25%. These regions support vertically aligned facilities capable of full-cycle production—from casting and CNC machining to final assembly—enabling rapid deployment of both manual and fully automated systems.

The supplier ecosystem offers scalable solutions across price tiers and automation levels. Buyers benefit from proximity to material sources, mature logistics networks, and a high density of technical talent. Standard delivery timelines range from 15–45 days depending on complexity, with cost advantages of 20–35% over equivalent European or North American-built equipment. The availability of modular designs allows customization for interlocking pavers, hollow blocks, or solid concrete units, supporting diverse construction needs in emerging and developed markets alike.

How to Choose Block Making Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001 for quality management systems. For exports to regulated markets, CE marking is essential for compliance with EU safety, health, and environmental requirements. Request documentation validating performance testing of core components including vibration motors, hydraulic presses, and mold systems.

Production Capability Assessment

Evaluate infrastructure indicators that reflect scalability and consistency:

- Facilities exceeding 3,000m² typically support continuous production lines

- In-house engineering teams enabling design modifications and automation integration

- CNC machining, welding, and heat treatment capabilities ensuring component durability

Cross-reference claimed output capacities with verified reorder rates (target >25%) and on-time delivery performance (ideal ≥97%).

Customization & After-Sales Support

Leading suppliers offer configurable options including block size, mold patterns, power source (electric/hydraulic), and feeding mechanisms. Confirm access to technical drawings, 3D renderings, and video demonstrations prior to order placement. Post-delivery support should include operator training, spare parts availability, and remote troubleshooting protocols.

Transaction Security Measures

Utilize secure payment frameworks such as escrow services to mitigate risk. Prioritize suppliers with transparent transaction histories, verifiable export records, and participation in third-party assurance programs. Pre-shipment inspection rights are critical—conduct factory audits or engage independent inspectors to validate machine functionality before dispatch.

What Are the Best Block Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Key Strengths |

|---|---|---|---|---|---|---|---|

| Gongyi Chenghui Machinery Equipment Co., Ltd. | Henan, CN | Brick Making Machinery (370) | 100% | 20% | ≤3h | US $60,000+ | Budget-friendly manual models; broad product range |

| Shandong Yinan Tengfei Machinery Co., Ltd. | Shandong, CN | Brick Making Machinery (236) | 100% | - | ≤3h | - | High-capacity automatic systems; robust build quality |

| Qingdao HF Machinery Technology Co., LTD | Shandong, CN | Customization Options (10+ parameters) | 100% | 28% | ≤5h | US $130,000+ | Advanced customization; color, size, pressure control |

| Changge Hengruide Machinery Equipment Co., Ltd. | Henan, CN | Other Construction Machinery (1,256) | 100% | 16% | ≤1h | US $10,000+ | Low-cost manual interlock machines; fast response |

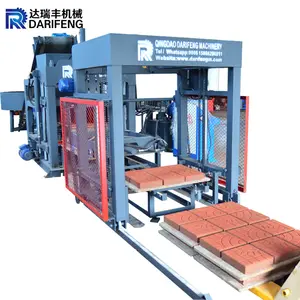

| Qingdao Darifeng Machinery Co., Ltd. | Shandong, CN | Customization + Automation Features | 97% | 54% | ≤5h | US $500,000+ | Premium automation; comprehensive technical support |

Performance Analysis

Suppliers like Qingdao Darifeng demonstrate strong customer retention (54% reorder rate), indicating high satisfaction with product reliability and service. Gongyi Chenghui and Changge Hengrude cater effectively to entry-level and small-scale operations with manual models priced between $85–$700 per unit. In contrast, Shandong-based manufacturers dominate mid-to-high-end segments, offering automatic and hydraulic models ranging from $7,000 to $32,000, suitable for commercial production environments. All top-tier suppliers maintain 100% on-time delivery records except Qingdao Darifeng (97%), which still performs within acceptable industry benchmarks. Response times under 5 hours ensure efficient communication, especially for time-sensitive technical clarifications.

FAQs

What is the typical MOQ and pricing structure for block making machines?

Minimum Order Quantity is generally 1 set or unit, even for automated models. Prices vary significantly by type: manual machines range from $85–$700, semi-automatic from $2,000–$15,000, and fully automatic systems from $15,000–$32,000. Bulk orders may qualify for container loading optimization and marginal discounts.

How long does it take to fulfill an order?

Standard production lead time is 15–30 days for manual and semi-automatic models. Fully automated or customized lines may require 30–45 days. Add 7–14 days for sea freight shipping to most global ports, or 3–7 days via air freight for critical components.

Can block making machines be customized for specific block types?

Yes, reputable suppliers offer mold changes for various block formats—including solid, hollow, interlocking, and paving stones. Customization extends to dimensions, surface textures, compression pressure, and automation level. Some providers support dual-mold configurations for flexible production runs.

Do suppliers provide installation and training support?

Most established exporters offer remote guidance via video tutorials and live calls. On-site installation and operator training can be arranged at additional cost, typically billed at $150–$250 per day plus travel expenses. Documentation is usually provided in English, Spanish, or French.

What materials are used in block making machine construction?

Frames are fabricated from high-tensile steel or cast iron for durability under continuous vibration. Critical wear parts—such as molds and plungers—are often treated with anti-corrosion coatings or hardened alloys. Hydraulic systems use industrial-grade seals and pumps rated for 5,000+ operating hours under load.