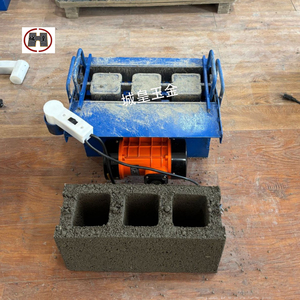

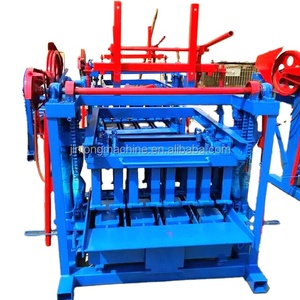

Manual Block Making Machine

Top sponsor listing

Top sponsor listing

About manual block making machine

Where to Find Manual Block Making Machine Suppliers?

China remains the central hub for manual block making machine production, with key manufacturing clusters in Henan and Shandong provinces driving supply chain efficiency. These regions host vertically integrated facilities that combine casting, machining, and assembly under one roof, enabling cost reductions of 20–30% compared to equivalent machinery produced outside Asia. Henan’s Gongyi city specializes in compact, human-powered models ideal for small-scale construction, while Shandong's industrial base focuses on modular designs with customizable mold configurations for interlock pavers, hollow blocks, and solid bricks.

The concentration of component suppliers—hydraulic stations, steel molds, vibration trays—within 50km radii supports rapid prototyping and low minimum order quantities (MOQs). Buyers benefit from lead times averaging 15–30 days for standard units, with localized access to raw materials such as manganese steel for wear-resistant parts and reinforced concrete frames. This ecosystem enables flexible sourcing for both individual entrepreneurs and bulk procurement managers across Africa, Southeast Asia, and Latin America.

How to Choose Manual Block Making Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across three core areas:

Technical Specifications & Customization Capability

Confirm compatibility with regional material standards: machines must process local cement-sand-aggregate mixes (typically 1:3 to 1:6 ratios) and produce blocks meeting national dimensional tolerances (e.g., 400×200×200mm ±2mm). Verify availability of interchangeable molds for hollow blocks, solid bricks, or interlocking paving stones. Top-tier suppliers offer configuration options for hydraulic pressure (8–15 tons), mold capacity (2–6 molds per cycle), and frame mobility (stationary vs. portable).

Production Infrastructure Verification

Assess operational scale through objective indicators:

- Minimum factory area of 2,000m² indicating dedicated production lines

- In-house fabrication capabilities including welding, CNC cutting, and heat treatment

- Presence of quality testing protocols for structural integrity and cycle durability

Cross-reference on-time delivery rates (target ≥98%) and response time (≤2 hours) as proxies for operational reliability.

Transaction Risk Mitigation

Prioritize suppliers with documented export experience and transaction safeguards. Request proof of past shipments to your region, particularly compliance with import regulations for construction equipment. Utilize secure payment mechanisms tied to inspection milestones. Pre-shipment verification should include video demonstrations of machine operation and sample block compression testing (target >15 MPa for standard concrete).

What Are the Best Manual Block Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Brick Making Machinery, Tile Making Machinery, Concrete Mixers | US $390,000+ | 100% | ≤2h | 57% | $100–120 | Yes – block size, color, mold shape, hydraulic station, truck integration |

| Changge Hengruide Machinery Equipment Co., Ltd. | Henan, CN | Other Construction Machinery, Crusher, Mining Equipment | US $10,000+ | 100% | ≤1h | 16% | $100–120 | Limited – basic interlock and hollow block variants |

| Gongyi Chenghui Machinery Equipment Co., Ltd. | Henan, CN | Brick Making Machinery, Crusher, Sand Making Machinery | US $60,000+ | 100% | ≤3h | 20% | $350–880 | Yes – oil-free, electricity-free models; small-scale variants |

| Gongyi Houde Machinery Equipment Co., Ltd | Henan, CN | Brick Making Machinery, Concrete Mixers, Loaders | US $50,000+ | 100% | ≤2h | 27% | $160–1,100 | Moderate – mobile units, dual-hole molds, South Africa-specific designs |

| Hebei Zhongke Jiantong Machinery Equipment Co., Ltd. | Hebei, CN | Brick Making Machinery, Concrete Pumps, Wood Crushers | US $80,000+ | 100% | ≤4h | <15% | $289–4,100 | Yes – includes semi-automatic hybrids and high-capacity QT4-24 model |

Performance Analysis

Shandong Hongfa stands out with the highest reorder rate (57%) and extensive customization depth, suggesting strong customer satisfaction and engineering flexibility. Despite higher pricing, Gongyi Chenghui and Hebei Zhongke target niche markets—off-grid operations and hybrid manual/semi-auto transitions—positioning them for specialized deployments. Changge Hengruide offers competitive entry-level pricing but lower reorder metrics, indicating potential gaps in post-sale support or product consistency. All listed suppliers maintain perfect on-time delivery records, though response speed varies significantly, with Henan-based firms generally faster than northern counterparts.

FAQs

What is the typical MOQ for manual block making machines?

Most suppliers accept orders starting at 1 unit, facilitating trial purchases. Bulk discounts typically apply at 5+ units, with container-load optimization possible at 10–20 sets depending on model dimensions.

What are common customization options?

Available modifications include mold type (solid/hollow/interlock), output capacity (2–6 blocks per press), frame portability, hydraulic system source (manual/diesel-assisted), and branding elements like logo imprinting. Some manufacturers support voltage-specific control panels for international use.

How long does production and shipping take?

Manufacturing lead time ranges from 10–25 days depending on customization level. Air freight delivers samples within 7–10 days; sea freight to major global ports averages 20–35 days. FOB terms are standard, with CIF available upon request.

Do suppliers provide technical documentation?

Reputable manufacturers supply operation manuals, assembly diagrams, maintenance schedules, and mold dimension specifications. ISO-certified firms often provide material test reports for critical load-bearing components.

Can I request a sample unit before bulk ordering?

Yes, all listed suppliers support single-unit orders for evaluation. Sample costs range from $160–$880 and may be partially credited toward future volume purchases. Video operation proofs are commonly offered free of charge.