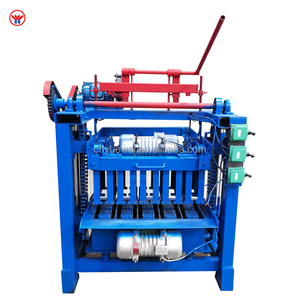

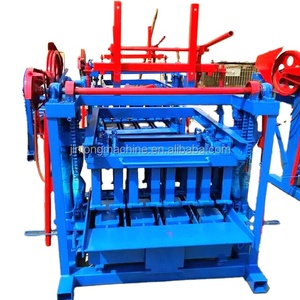

Manual Cement Block Making Machine

Top sponsor listing

Top sponsor listing

1/28

1/28

1/16

1/16

1/33

1/33

1/5

1/5

1/24

1/24

About manual cement block making machine

Where to Find Manual Cement Block Making Machine Suppliers?

China remains the global epicenter for manual cement block making machine production, with key manufacturing clusters in Henan, Shandong, and Shaanxi provinces. These regions host vertically integrated supply chains that streamline component sourcing—from steel fabrication to mold casting—reducing unit costs by 20–30% compared to non-specialized manufacturers. Henan alone accounts for over half of China’s brick machinery exporters, supported by mature logistics networks enabling efficient container loading at major ports like Qingdao and Shanghai.

The industrial ecosystems in these zones enable rapid prototyping and scalable production, with many suppliers operating end-to-end facilities capable of fulfilling orders from 1 set to full-container batches within 15–30 days. Buyers benefit from localized access to raw materials, skilled labor pools, and ancillary services such as packaging design and export documentation. This concentration supports competitive pricing, especially for standard models like hollow block or interlocking paver machines, while maintaining flexibility for custom configurations in mold size, output capacity, and material handling systems.

How to Choose Manual Cement Block Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance Standards

Verify adherence to internationally recognized quality management systems such as ISO 9001. While not all suppliers list formal certifications in public profiles, consistent on-time delivery rates (≥98%) and low reorder rates (<15%) serve as proxy indicators of process reliability. For regulated markets, confirm compliance with CE or equivalent safety standards prior to shipment.

Production and Customization Capability

Assess core competencies through available data points:

- Suppliers offering customization options (mold shape, color, capacity, labeling) typically maintain in-house engineering teams

- Diesel-powered, hydraulic, and hand-operated variants indicate diverse production lines

- Presence of related machinery (concrete mixers, crushers, tile makers) suggests integrated manufacturing capability

Cross-reference product listings with response times (≤3 hours is typical) and online revenue metrics (e.g., US $200,000+ annual digital sales) to gauge business scale and customer engagement levels.

Transaction Risk Mitigation

Prioritize suppliers with documented performance records, including verified on-time delivery (100% among top-tier vendors). Utilize secure payment mechanisms where possible, and request physical or digital inspection reports before release of funds. Pre-shipment testing should include mold alignment verification, pressure tolerance checks, and finished block dimensional accuracy against ASTM C990 or local building codes.

What Are the Best Manual Cement Block Making Machine Suppliers?

| Company Name | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (Count) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Tancheng County Hongbaoyuan Machinery Co., Ltd. | Custom Manufacturer | Brick Making Machinery, Concrete Mixers, Crushers | US $200,000+ | 100% | ≤3h | <15% | 13 | Yes (mold, size, capacity, label, logo) |

| Gongyi Chenghui Machinery Equipment Co., Ltd. | Manufacturer | Brick Making Machinery, Sand Makers, Tire Shredders | US $60,000+ | 100% | ≤3h | 20% | 5 | Limited (model-specific variants) |

| Changge Hengrude Machinery Equipment Co., Ltd. | Manufacturer | Interlock Block Machines, Drilling Rigs, Crushers | US $10,000+ | 100% | ≤1h | 16% | 5 | Yes (household/manual designs, interlocking molds) |

| Shaanxi Qintao Machinery Technology Co., Ltd. | Manufacturer | Brick Makers, Tile Machines, Axial Fans | US $210,000+ | 100% | ≤2h | <15% | 5 | Yes (diesel, hydraulic, solid/hollow block types) |

| Hebei Zhongke Jiantong Machinery Equipment Co., Ltd. | Manufacturer | Semi-Automatic Brick Presses, Concrete Pumps | US $80,000+ | 100% | ≤4h | <15% | 5 | Yes (electric/manual hybrid, multi-hole molds) |

Performance Analysis

Tancheng Hongbaoyuan and Shaanxi Qintao lead in both volume and customization breadth, supported by high digital revenue streams and diversified product portfolios. Their sub-15% reorder rates suggest strong first-time quality execution, minimizing repeat issues. Changge Hengrude stands out for responsiveness (≤1h average), ideal for time-sensitive procurement cycles. Gongyi Chenghui shows a higher reorder rate (20%), which may reflect either customer satisfaction or iterative order patterns common in niche applications such as oil-free, electricity-free models.

Suppliers with broader machinery ranges (e.g., concrete cutters, sand makers) often possess more robust foundry and machining infrastructure, enhancing durability of critical components like hoppers and molds. Buyers seeking long-term partnerships should prioritize companies with proven track records in international shipping, responsive communication, and modular design capabilities for future scalability.

FAQs

What is the typical MOQ and pricing range for manual cement block making machines?

Minimum order quantities are generally set at 1 unit, facilitating small-scale trials. Pricing varies significantly by model: basic handheld interlock machines start at $90–120/unit, while semi-automatic or diesel-assisted models range from $500–$1,300/set. Industrial-grade units with electric motors exceed $3,400.

How long does production and shipping take?

Standard lead time for ready-to-ship units is 7–15 days post-payment confirmation. Sea freight adds 20–40 days depending on destination port. Air shipping reduces transit time to 5–10 days but increases cost proportionally, particularly for heavy machinery.

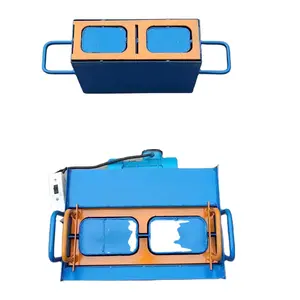

Can I customize mold designs for specific block shapes?

Yes, most established suppliers offer mold customization for hollow blocks, solid bricks, interlocking pavers, and decorative panels. Provide technical drawings or sample specifications for feasibility assessment. Turnaround for new mold development typically ranges from 10–20 days.

Do suppliers provide after-sales support or technical guidance?

Support levels vary. Leading manufacturers offer instructional videos, assembly manuals, and remote troubleshooting. Some provide on-site training or partner with local agents for maintenance. Confirm service availability in your region before finalizing contracts.

Are spare parts readily available?

Common wear components—such as seals, plungers, and mold plates—are typically stocked by suppliers. Request a spare parts list and pricing schedule during negotiation. Long-term buyers may negotiate inclusion of initial spare kits with bulk purchases.