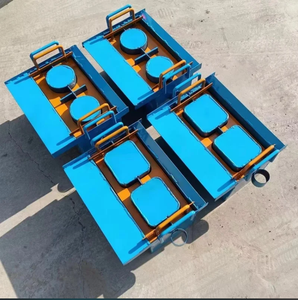

Manual Concrete Block Machine

About manual concrete block machine

Where to Find Manual Concrete Block Machine Suppliers?

China remains the central hub for manual concrete block machine manufacturing, with key production clusters in Henan and Hebei provinces driving supply chain efficiency. Henan, home to over 60% of China’s brick-making machinery producers, benefits from integrated industrial ecosystems centered around Zhengzhou and Gongyi, where access to steel, casting, and logistics infrastructure reduces production lead times by up to 25%. Hebei’s machinery corridor near Shijiazhuang specializes in compact, low-cost models suited for small-scale construction, leveraging regional access to automotive components for simplified mechanical actuation systems.

These regions support vertically integrated operations—ranging from raw material processing to final assembly—enabling suppliers to maintain tight control over cost and quality. Buyers benefit from localized component sourcing, which lowers unit prices by 15–30% compared to non-Asian manufacturers. Typical advantages include rapid prototyping (within 7–14 days), MOQ flexibility (as low as 1 set), and scalability for both domestic and export orders. Average lead times for standard units range from 15 to 30 days, with express shipping options available for spot inventory.

How to Choose Manual Concrete Block Machine Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify that machines meet structural durability standards for mold compression (typically 4–8 tons of pressing force). While formal certifications like ISO 9001 or CE are not universally present among smaller exporters, prioritize suppliers who provide test reports on frame integrity, wear resistance of molds, and ergonomic handling. Machines designed for continuous use should feature reinforced steel frames and replaceable die sets.

Production and Customization Capacity

Assess supplier capability through the following indicators:

- Minimum factory footprint of 3,000m² indicating serious production scale

- In-house machining capabilities for molds and hydraulic/pneumatic components

- Offering customization for block size (e.g., 200mm, 400mm), cavity configuration (solid/hollow), and manual operation ergonomics

Cross-reference product listings with reorder rates above 20% and response times under 4 hours as proxies for reliability and customer satisfaction.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services, especially when dealing with new suppliers lacking extensive transaction histories. Request sample units to evaluate build quality, ease of operation, and output consistency (blocks per hour). Confirm packaging standards for international shipping to prevent deformation during transit. Prioritize suppliers with documented on-time delivery performance (target ≥95%) and responsive communication channels.

What Are the Best Manual Concrete Block Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Gongyi Chenghui Machinery Equipment Co., Ltd. | Henan, CN | Brick Making Machinery, Concrete Mixers, Crushers | US $60,000+ | 100% | ≤4h | 20% | $480–880 | No |

| Hebei Zhongke Jiantong Machinery Equipment Co., Ltd. | Hebei, CN | Brick Making Machinery, Concrete Pumps, Drilling Rigs | US $80,000+ | 100% | ≤4h | <15% | $289–4,100 | No |

| Linyi Fulang Machinery Co., Ltd. | Shandong, CN | Concrete Block Machines, Custom Fabrication | US $30,000+ | 85% | ≤2h | <15% | $800–4,900 | Yes |

| Zhengzhou Summit Trading Co., Ltd. | Henan, CN | Brick Making Machinery, Mortar Spray Machines, Loaders | US $50,000+ | 100% | ≤1h | 25% | $700–840 | No |

| Asia Techno Group LLC | Unknown | Semi-Automatic & Mobile Block Machines | Not Available | Unverified | ≤11h | Unverified | $2,300–19,450 | No |

Performance Analysis

Gongyi Chenghui and Zhengzhou Summit stand out for consistent on-time delivery (100%) and competitive pricing, making them reliable choices for entry-level manual machines. Hebei Zhongke offers the widest price range, including ultra-low-cost models ($289/set), ideal for budget-conscious buyers in developing markets. Linyi Fulang is the only supplier in this group offering customization for color, logo, and packaging, despite a lower on-time delivery rate (85%). Zhengzhou Summit leads in responsiveness (≤1h average reply time) and has the highest reorder rate (25%), suggesting strong post-sale satisfaction. Asia Techno Group lists higher-end semi-automatic variants but lacks verifiable performance metrics, introducing procurement risk for first-time buyers.

FAQs

How to verify manual concrete block machine supplier reliability?

Cross-check online revenue data, reorder rates, and on-time delivery percentages provided by business platforms. Request reference projects or client contacts when available. Evaluate responsiveness and technical clarity during pre-sales inquiries as an indicator of service quality.

What is the typical MOQ and lead time?

Most suppliers offer a minimum order quantity of 1 set, facilitating trial purchases. Standard lead times range from 15 to 25 days after order confirmation. Spot goods may be shipped within 3–7 days if inventory is available.

Can I customize the machine for specific block sizes or branding?

Limited customization is available. Only select suppliers, such as Linyi Fulang Machinery, offer modifications to mold dimensions, color, or branding. Most manufacturers adhere to standard configurations (e.g., 4-piece 200mm blocks) to maintain production efficiency.

Are samples available before bulk ordering?

Yes, most suppliers allow single-unit purchases as functional samples. Sample costs typically reflect full unit pricing, though some may apply discounts upon confirmation of future volume orders.

What are the common materials used in construction?

Machines are primarily built using carbon steel frames with Q235 or Q345-grade steel for load-bearing components. Molds are often made from hardened manganese steel to resist abrasion. Hand-operated levers and supports utilize welded steel tubing with powder-coated finishes for corrosion resistance.