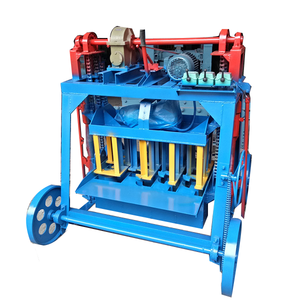

Concrete Block Automatic Machine

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

About concrete block automatic machine

Where to Find Concrete Block Automatic Machine Suppliers?

China remains the global epicenter for concrete block automatic machine manufacturing, with key production hubs concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine advanced fabrication capabilities with efficient logistics networks. Shandong’s machinery corridor—centered around Qingdao and Jining—specializes in fully automated systems designed for high-volume output, leveraging proximity to steel and hydraulic component suppliers to reduce material costs by 15–20%. Henan, home to over half of China’s construction equipment manufacturers, emphasizes modular and semi-automatic solutions ideal for mid-scale operations, supported by Zhengzhou’s central rail and port connectivity enabling rapid export fulfillment.

The clustering effect allows suppliers to maintain tight control over supply chains, from casting and CNC machining to final assembly, often within a single facility or localized network. This integration translates into shorter lead times (typically 30–45 days for standard configurations), competitive pricing due to economies of scale, and flexibility in accommodating custom engineering requests. Buyers benefit from access to mature technical talent pools and established export channels, particularly for shipments to Southeast Asia, Africa, and Latin America.

How to Choose Concrete Block Automatic Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across three critical dimensions:

Technical and Operational Compliance

Verify ISO 9001 certification as a baseline indicator of quality management. For international deployment, ensure CE marking compliance to meet EU safety, health, and environmental standards. Request documentation on core system validations, including hydraulic pressure testing, mold alignment precision, and electrical control panel design. Confirm compatibility with local power grids (e.g., 380V/50Hz or 220V/60Hz) and assess motor specifications (diesel vs. electric) based on site infrastructure.

Production Capacity and Engineering Capabilities

Evaluate the following operational benchmarks:

- Minimum factory area of 3,000m² indicating scalable production capacity

- In-house design teams capable of modifying mold configurations, conveyor layouts, and batching systems

- Proven experience with customization parameters such as block size (standard: 400×200×200mm; customizable up to 600×300×240mm), shape (solid, hollow, interlocking), and material blends (including fiber-reinforced or fly ash composites)

- Integration of optional components like solar-powered feeders, pallet recycling units, or automated stacking conveyors

Cross-reference declared capabilities with verified on-time delivery rates above 97% and response times under 3 hours to gauge operational responsiveness.

Transaction Security and Quality Assurance

Utilize secure payment mechanisms such as escrow services to protect against non-delivery or specification mismatches. Prioritize suppliers offering sample units for performance validation—benchmark cycle time (typically 15–25 seconds per cycle), dimensional accuracy (±1mm tolerance), and long-term durability under continuous operation. Insist on post-shipment support, including remote troubleshooting, spare parts availability, and operator training protocols.

What Are the Best Concrete Block Automatic Machine Suppliers?

| Company Name | Location | Verification Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range |

|---|---|---|---|---|---|---|---|---|

| Shandong Shiyue Intelligent Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | Brick Making Machinery, Concrete Batching Plant, Tile Making Machinery | US $1,400,000+ | 100% | ≤2h | 33% | 13+ models, full automation with optional solar & fiber-glass integration |

| Shandong Canhua International Trade Co., Ltd. | Shandong, CN | Multispecialty Supplier | Brick Making Machinery, Concrete Mixers | US $230,000+ | 100% | ≤3h | <15% | 5 models, QT4–QT8 series, hydraulic-driven with pallet/mold customization |

| Henan Best Link Import And Export Trading Co., Ltd. | Henan, CN | Not Specified | Brick Making Machinery, Mining Machines, Concrete Mixers | US $250,000+ | 100% | ≤1h | <15% | 5 models, price range $780–$9,800, includes diesel-powered variants |

| Henan Canary Machinery Equipment Co., Ltd. | Henan, CN | Not Specified | Concrete Mixers, Rebar Machinery, Road Equipment | US $40,000+ | 100% | ≤2h | 15% | 5 models, CR-series, all priced at $543/set – indicative of entry-level automation |

| SUMU (Shanghai) Automation Engineering Co., Ltd. | Shanghai, CN | Not Specified | Brick Making Machinery, AAC Block Systems, Concrete Mixers | US $10,000+ | 100% | ≤2h | 20% | 5 listed products, wide price spread ($4,000–$230,000), includes AAC lightweight block lines |

Performance Analysis

Shandong Shiyue stands out with the highest online revenue and a 33% reorder rate, reflecting strong customer retention and broad product adaptability, including solar-integrated and fiber-reinforced block production. Its extensive customization options—from mold design to labeling and packaging—position it as a strategic partner for buyers seeking differentiated output. Shandong Canhua offers mid-range automation with solid technical specs but a lower reorder rate, suggesting room for improvement in post-sale engagement. Henan Best Link combines fast response times (≤1h) with cost-effective diesel-driven models, suitable for off-grid applications. Henan Canary’s uniform pricing indicates standardized, low-complexity machines likely aimed at budget-conscious markets. SUMU presents the widest capability spectrum, including high-end AAC (autoclaved aerated concrete) systems, making it ideal for specialized lightweight block production despite limited transaction volume.

FAQs

How to verify concrete block machine supplier reliability?

Validate certifications through official registries and request factory audit reports or video walkthroughs. Analyze transaction history for consistent on-time delivery and examine customer feedback for insights into after-sales service, technical support, and machine uptime performance.

What is the typical lead time for concrete block automatic machines?

Standard models typically ship within 30–45 days after order confirmation. Customized systems with unique mold designs or automation features may require 60–75 days, depending on complexity and component availability.

What are common customization options?

Suppliers commonly offer adjustments in block dimensions (e.g., 400×200×150mm to 600×300×240mm), shape (solid, hollow, paver, interlocking), material composition (addition of fibers, fly ash, or recycled aggregates), and operational features such as motor type (electric/diesel), feeder configuration, and control panel language.

Do suppliers provide installation and training support?

Most established manufacturers offer remote guidance via video or manuals. Some provide on-site technician dispatch (at additional cost) for commissioning, operator training, and process optimization, particularly for turnkey or high-capacity installations.

Can concrete block machines be shipped globally?

Yes, experienced exporters manage FOB, CIF, and DDP shipping terms. Sea freight is standard for full-container loads due to machine weight (ranging from 2–20 tons). Ensure compliance with destination country regulations regarding electrical systems, safety guards, and noise emissions.