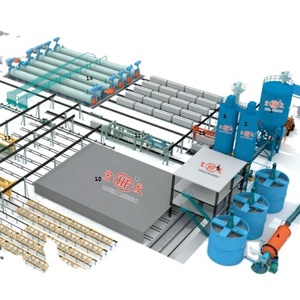

Automatic Cement Block Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

About automatic cement block making machine

Where to Find Automatic Cement Block Making Machine Suppliers?

China remains the dominant hub for automatic cement block making machine manufacturing, with key production clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine raw material processing, heavy fabrication, and final assembly under one supply chain. Shandong's Jining and Linyi zones specialize in medium-to-large scale fully automatic systems, supported by proximity to steel foundries and port logistics, reducing component lead times by up to 25%. Henan, particularly around Zhengzhou, is home to over half of China’s brick and block machinery exporters, offering scalable production capacity and competitive pricing due to high supplier density and mature subcontractor networks.

The regional infrastructure enables rapid prototyping and volume manufacturing, with many suppliers operating facilities exceeding 5,000m² and maintaining in-house CNC machining, welding lines, and hydraulic system integration. Buyers benefit from localized access to concrete mixer manufacturers, mold fabricators, and conveyor system integrators within a 50km radius, streamlining customization and after-sales support. Average lead times range from 30–45 days for standard models, while production costs remain 20–30% below Western or Southeast Asian alternatives due to optimized labor and logistics efficiency.

How to Choose Automatic Cement Block Making Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001 for quality management and CE marking for mechanical safety compliance—essential for market entry in Europe and regulated construction sectors. Request documentation on hydraulic system testing, vibration frequency calibration, and structural load analysis. Machines designed for export should meet IEC electrical standards and include dual-language control panels (e.g., English + Chinese).

Production Capability Assessment

Evaluate core manufacturing indicators:

- Minimum factory area of 3,000m² to ensure batch production scalability

- In-house engineering teams capable of customizing mold designs, power configurations (electric/diesel), and automation levels

- Integrated production lines including mold casting, frame welding, and PLC-controlled assembly

Cross-reference supplier claims with verifiable metrics such as on-time delivery performance (>90%) and reorder rates (>25%) to assess reliability.

Customization & Technical Flexibility

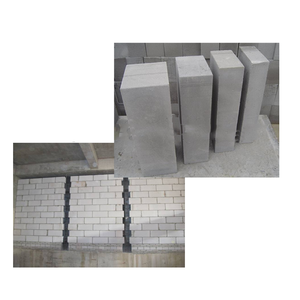

Leading suppliers offer configurable options including block size (e.g., 4” to 16” hollow/solid blocks), output capacity (QT4-15: ~1,500 blocks/hour; QT10-15: ~3,500 blocks/hour), and raw material compatibility (cement-sand, fly ash, slag mixtures). Confirm availability of modular add-ons like belt conveyors, silo feeding systems, and curing stacks. Suppliers with design capabilities can provide CAD drawings and operational schematics within 72 hours of inquiry.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party inspection services (e.g., SGS, BV) and secure payment terms via escrow. Analyze historical transaction data where available, focusing on response time (ideal ≤2 hours), dispute resolution history, and post-delivery service responsiveness. Pre-shipment testing—including dry runs and video demonstrations—is recommended before release of final payment.

What Are the Best Automatic Cement Block Making Machine Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Main Product Focus | Customization Capability |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Custom Manufacturer | 100% | 57% | ≤2h | US $370,000+ | Brick/Tile/Pipe Making Machinery | High (block size, color, power, mold, material mix) |

| Linyi Yingcheng International Trade Co., Ltd. | Shandong, CN | - | 80% | 60% | ≤1h | US $240,000+ | Brick Making Machinery | Medium (machine model, pallet, phase, block shape) |

| Henan Best Link Import And Export Trading Co., Ltd. | Henan, CN | - | 100% | <15% | ≤1h | US $250,000+ | Brick Making Machinery, Concrete Mixers | Limited (basic model variants) |

| Shandong Weida Construction Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | 77% | 25% | ≤3h | US $210,000+ | Brick Making Machinery, AAC Systems | High (full line automation, motor, mold, packaging) |

| Electra Engineering Ltd | - | - | - | - | ≤2h | - | Brick Making Machinery, Concrete Batching Plants | Medium (standard models at competitive pricing) |

Performance Analysis

Shandong-based suppliers dominate in customization depth and vertical integration, with Shandong Hongfa and Weida offering full-line solutions from raw material handling to finished block stacking. Hongfa stands out with a 100% on-time delivery rate and strong reorder volume, indicating consistent customer satisfaction. Linyi Yingcheng demonstrates high buyer retention (60% reorder rate), reflecting effective post-sale engagement despite an 80% delivery rate. Henan Best Link achieves perfect punctuality but has low repeat business, suggesting potential gaps in long-term support or product differentiation. Weida offers broad technical configurability but lags in response speed and delivery consistency. Electra Engineering lacks verifiable performance metrics, introducing procurement risk despite competitively priced offerings (e.g., $15,000–$20,000 for QT10-15 models).

FAQs

What is the typical MOQ and pricing range for automatic cement block making machines?

Minimum order quantity is typically 1 set. Pricing varies significantly by automation level and output: semi-automatic models start at $2,700–$6,500, mid-range fully automatic units (QT4 series) range from $9,500–$13,000, while high-capacity lines (QT10-15 and above) reach $15,000–$65,900 depending on configuration.

How long does it take to fulfill an order?

Standard orders require 30–45 days for production and pre-shipment preparation. Customized systems with extended conveyors, silos, or specialized molds may extend lead times to 60 days. Air freight sampling takes 7–10 days globally; sea freight averages 20–35 days depending on destination port.

Can suppliers customize machine specifications?

Yes, leading manufacturers support customization of block dimensions (e.g., interlock, solid, paver), production capacity, power source (3-phase electric or diesel hydraulic station), control panel language, and integration with auxiliary equipment like mixers and stackers. Full technical drawings and operational simulations are typically provided prior to production.

Do suppliers provide installation and training support?

Many offer remote setup guidance via video and manuals. On-site technician deployment is available from premium suppliers, often at additional cost. Training usually covers machine operation, maintenance protocols, mold replacement, and troubleshooting common faults (e.g., uneven compaction, hydraulic pressure drops).

What are common payment and shipping terms?

Common terms include T/T (30% deposit, 70% before shipment), with some suppliers accepting L/C or platform-backed transactions. FOB terms are standard; CIF can be arranged upon request. Full container loads (20ft or 40ft) are typical for single-machine shipments, with disassembly and protective coating applied for corrosion resistance during transit.