Semi Automatic Concrete Block Making Machine

Top sponsor listing

Top sponsor listing

TR

TR

CN

CN

CN

CN

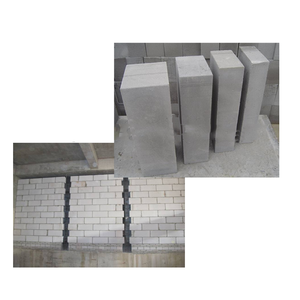

About semi automatic concrete block making machine

Where to Find Semi Automatic Concrete Block Making Machine Suppliers?

China remains the global epicenter for semi automatic concrete block making machine production, with key manufacturing clusters in Henan and Shandong provinces. These regions host vertically integrated industrial ecosystems that streamline component sourcing, fabrication, and final assembly. Henan, home to over 60% of China’s construction machinery suppliers, benefits from dense networks of steel, hydraulics, and mold manufacturers within a 50km radius, reducing material procurement time by up to 40%. Shandong’s proximity to major ports like Qingdao enables faster export logistics, with average shipment lead times 10–15 days shorter than inland competitors.

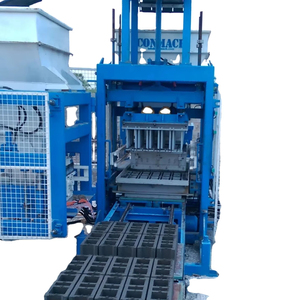

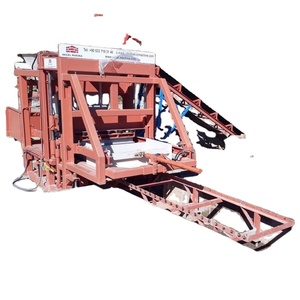

The concentration of specialized labor and mature supply chains allows suppliers to offer competitive pricing—typically 20–30% below Western market rates—while maintaining scalability. Most factories support monthly outputs ranging from 30 to 100 units depending on model complexity. Buyers gain access to flexible production lines capable of manufacturing hollow blocks, solid bricks, pavers, and interlocking tiles using vibration molding and hydraulic pressing techniques. Common raw materials include cement, fly ash, sand, slag, and recycled aggregates, processed through batch mixers and automated feeding systems.

How to Choose Semi Automatic Concrete Block Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international quality standards such as ISO 9001. While not all suppliers list CE certification explicitly, it is essential for compliance in European and North American markets. Request documentation on hydraulic system performance, vibration frequency (typically 4,000–6,000 vibrations per minute), and mold durability tested under continuous operation.

Production Capability Verification

Assess core manufacturing infrastructure:

- Minimum factory area of 3,000m² to ensure stable output capacity

- In-house capabilities for CNC machining, welding, and mold design

- Dedicated R&D or engineering teams for customization support

Cross-reference response times (target ≤2 hours) and on-time delivery rates (ideal ≥97%) as indicators of operational efficiency.

Procurement Safeguards

Utilize secure payment mechanisms such as third-party escrow services until post-delivery inspection is completed. Prioritize suppliers with documented after-sales service policies, including spare parts availability and remote technical guidance. Conduct pre-shipment inspections via video audit or third-party agencies to verify machine functionality and configuration accuracy.

What Are the Best Semi Automatic Concrete Block Making Machine Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Custom Manufacturer | Brick Making Machinery, Tile Making Machinery, Pipe Making Machinery, Concrete Mixers | 100% | 57% | ≤2h | US $370,000+ | Yes (diesel/hydraulic station, block size, color, logo, power) |

| Changge Hengrude Machinery Equipment Co., Ltd. | Manufacturer | Other Construction Machinery, Crusher, Mining Equipment | 100% | 16% | ≤1h | US $10,000+ | Limited (basic models across QT4 series) |

| Henan Longyu Machinery Equipment Co., Ltd. | Manufacturer | Brick Making Machinery, Crusher, Wood Pellet Mills | 100% | 38% | ≤1h | US $60,000+ | Moderate (mobile/manual variants, hollow/paving types) |

| LONTA MACHINERY CO.,LTD | Manufacturer | Concrete Mixers, Compactors, Brick Making Machinery | 87% | <15% | ≤3h | US $40,000+ | Yes (QTJ4 series with varying capacity and voltage) |

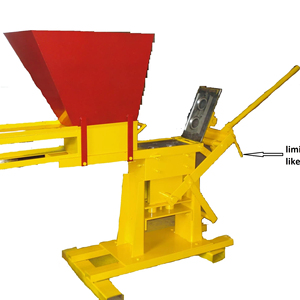

| Gongyi Yuewei Machinery Co., Ltd. | Manufacturer | Brick Making Machinery, Crusher, Concrete Mixers | 100% | 25% | ≤2h | US $10,000+ | Yes (manual/semi-auto mobile units, multiple molds) |

Performance Analysis

Shandong Hongfa stands out with the highest reorder rate (57%) and substantial online revenue, indicating strong customer retention and proven export capability. Its broad customization scope—from diesel-powered stations to branded labeling—makes it ideal for buyers requiring differentiated product offerings. Changge Hengrude and Henan Longyu demonstrate exceptional responsiveness (≤1h), enabling rapid quote turnaround and issue resolution. LONTA MACHINERY offers higher-end models with prices exceeding $7,000, though its lower on-time delivery rate (87%) warrants closer logistical scrutiny. Gongyi Yuewei provides balanced flexibility with mid-range pricing and verified 100% on-time fulfillment. For high-volume contracts, prioritize suppliers with both customization capacity and consistent delivery performance.

FAQs

What is the typical MOQ and lead time for semi automatic block machines?

Minimum Order Quantity is typically 1 unit, allowing sample testing before bulk procurement. Standard lead times range from 15 to 30 days for production, with an additional 10–25 days for international shipping depending on destination and freight mode.

Can I customize block shape, size, and production capacity?

Yes, most established suppliers support customization of mold configurations for block dimensions (e.g., 400×200×150mm standard), shapes (solid, hollow, interlocking), and hourly output (ranging from 800 to 3,000 blocks/hour). Voltage (220V/380V), power source (electric/diesel), and conveyor integration are also adjustable.

Do suppliers provide technical support and installation guidance?

Reputable manufacturers offer remote assistance via video call or manuals. Some provide on-site technician deployment at additional cost. Ensure spare parts kits (vibration motors, hydraulic seals, control panels) are included or available separately.

How are machines packaged and shipped internationally?

Machines are generally packed in nude or wrapped with protective film on wooden pallets, suitable for container loading (20ft or 40ft FCL). FOB terms are common, but suppliers may arrange CIF shipping upon request. Confirm inclusion of export documentation for customs clearance.

Is sample testing recommended before full procurement?

Yes. Procuring a single-unit sample allows verification of build quality, block consistency, and operational stability. Benchmark output against specified parameters—such as cycle time (15–25 seconds per mold) and compression pressure (10–18 MPa)—before placing volume orders.