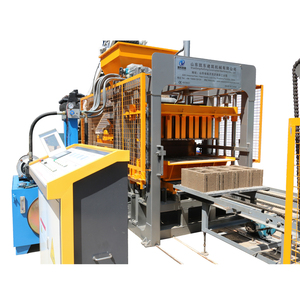

Cement Block Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

About cement block making machine

Where to Find Cement Block Making Machine Suppliers?

China remains the global epicenter for cement block making machine manufacturing, with key production clusters in Henan and Shanghai driving innovation and export volume. Henan Province accounts for over 70% of China’s brick machinery suppliers, supported by a mature industrial ecosystem that includes raw material processing, casting, CNC machining, and logistics networks. The region's proximity to major rail and highway corridors enables efficient domestic distribution and containerized exports through Qingdao and Tianjin ports.

Shanghai-based manufacturers leverage advanced automation engineering expertise, particularly in control systems integration and dual-power (diesel-electric) configurations. These clusters benefit from vertically integrated supply chains—reducing component lead times by 25–40% compared to fragmented production regions. Buyers gain access to scalable facilities capable of fulfilling both small-batch trials and bulk orders (10+ units), typically within 30–60 days. Localized production also supports cost efficiency, with average machine prices 20–35% below European or North American equivalents.

How to Choose Cement Block Making Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international safety and performance standards. While ISO 9001 certification is not universally listed, it should be requested as a baseline for quality management. For markets requiring regulatory compliance (EU, USA, GCC), confirm CE marking or equivalent documentation for electrical systems, vibration mechanisms, and structural integrity testing.

Production Capability Assessment

Evaluate supplier infrastructure using available metrics:

- Facility size and specialization: Prioritize suppliers listing 100+ product variants or dedicated R&D in block molding technology

- In-house manufacturing capabilities: Look for evidence of mold design, vibratory system calibration, and motor integration

- Customization depth: Confirm availability of adjustable pallet sizes, interchangeable molds, color dosing systems, and power source options (electric/diesel)

Cross-reference on-time delivery rates (target ≥96%) and response times (≤2 hours preferred) as proxies for operational reliability. High reorder rates (>20%) indicate customer satisfaction and consistent output quality.

Transaction Safeguards

Utilize secure payment methods such as escrow services where funds are released only after shipment confirmation. Request sample units to validate build quality, cycle time accuracy, and block dimensional consistency. Conduct video audits to verify factory operations and inventory readiness before placing large orders.

What Are the Best Cement Block Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Gongyi Xiaoyi Hongying Machinery Factory | Henan, CN | Brick Making Machinery (1,705) | 96% | ≤3h | 36% | $200,000+ | High (14 models) | $450–$1,400 |

| SUMU (Shanghai) Automation Engineering Co., Ltd. | Shanghai, CN | Brick Making Machinery (206) | 100% | ≤2h | 20% | $10,000+ | Moderate (5 models) | $410–$5,000 |

| Changge Hengrude Machinery Equipment Co., Ltd. | Henan, CN | Other Construction Machinery (1,256) | 100% | ≤1h | 16% | $10,000+ | Moderate (5 models) | $100–$2,200 |

| Henan Kexuan Brick Machinery Equipment Co., Ltd. | Henan, CN | Not specified | 100% | ≤1h | 21% | $140,000+ | Moderate (5 models) | $360–$1,250 |

| Gongyi Chenghui Machinery Equipment Co., Ltd. | Henan, CN | Brick Making Machinery (366) | 100% | ≤4h | 20% | $80,000+ | Moderate (5 models) | $490–$1,790 |

Performance Analysis

Gongyi Xiaoyi Hongying stands out for product diversity and strong reorder performance (36%), indicating high market acceptance. Despite slightly lower on-time delivery (96%), its extensive listing volume suggests robust production capacity and mature export processes. SUMU (Shanghai) distinguishes itself with full punctuality and rapid response, reflecting streamlined operations and potential strength in automated system integration. Changge Hengrude and Henan Kexuan offer competitive pricing and fast communication, ideal for buyers prioritizing responsiveness and entry-level equipment.

Henan-based suppliers dominate in scale and specialization, with three of five companies focusing heavily on brick machinery. All top performers maintain 100% on-time delivery except Hongying, reinforcing regional strengths in logistics execution. Price stratification reflects automation level: manual models start under $200, while semi-automatic and dual-power systems range between $750–$2,200. Fully automatic lines exceed $4,000, aligning with commercial-scale production needs.

FAQs

How to verify cement block making machine supplier reliability?

Request verifiable documentation including business licenses, production facility photos, and third-party inspection reports. Validate claims about delivery performance and reorder rates through transaction history analysis. Conduct virtual factory tours to assess assembly lines, quality control checkpoints, and inventory levels.

What is the typical lead time for cement block making machines?

Standard order fulfillment ranges from 25 to 45 days, depending on customization complexity. Simple manual models can ship within 15 days, while fully automated systems with custom molds may require 60 days. Pre-shipment inspections add 3–7 days if conducted by third parties.

Can suppliers customize machine specifications?

Yes, most suppliers offer customization for block size, mold configuration, conveyor length, motor type (electric/diesel), and control panel language. Advanced options include PLC controls, color mixing systems, and vibration frequency adjustment. Confirm whether CAD drawings or prototype validation are provided prior to production.

Do manufacturers provide after-sales support?

Support varies by supplier. Leading vendors offer installation guides, operation videos, and remote troubleshooting. Some provide technician dispatch services at additional cost. Clarify warranty terms (typically 12 months on core components) and spare parts availability before purchase.

What are common MOQ and payment terms?

Minimum Order Quantity is typically 1 set for standard models, enabling trial purchases. Payment terms often include T/T (30% deposit, 70% before shipment), with some suppliers accepting Trade Assurance or L/C for larger contracts. Bulk discounts apply at 5+ units, improving unit economics by 8–15%.