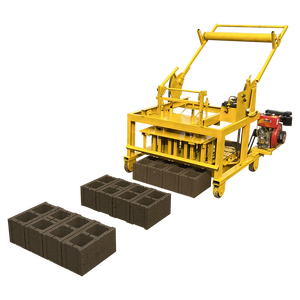

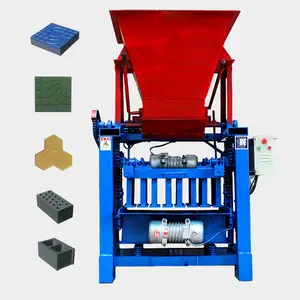

Manual Block Machine Maker

1/12

1/12

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/12

1/12

1/25

1/25

1/3

1/3

1/22

1/22

1/3

1/3

0

0

1/1

1/1

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/17

1/17

About manual block machine maker

Where to Find Manual Block Machine Makers?

China remains the global epicenter for manual block machine manufacturing, with key production clusters in Henan and Shandong provinces. These regions host vertically integrated supply chains that support rapid prototyping and cost-efficient production. Henan specializes in compact, portable models suited for small-scale construction, while Shandong focuses on durable, high-output manual systems designed for interlocking brick applications. Proximity to raw material sources—particularly steel and casting foundries—enables a 15–25% cost advantage over non-Asian manufacturers.

The industrial ecosystems in these zones feature tightly coordinated networks of component suppliers, fabrication workshops, and logistics providers operating within localized hubs. This integration supports lean manufacturing practices, reducing lead times to 20–35 days for standard orders. Buyers benefit from scalable production capacity, with many suppliers capable of fulfilling bulk orders (10+ units) without significant delays. Additionally, regional specialization allows for targeted sourcing: Henan-based makers emphasize lightweight, soil-compressed models, whereas Shandong producers prioritize oil-free, electricity-independent designs ideal for off-grid environments.

How to Choose Manual Block Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm machine compatibility with intended materials—commonly laterite, mud, or concrete mixtures. Verify design features such as mold adjustability, compression force (typically 4–6 tons), and absence of electrical or hydraulic dependencies where applicable. While formal certifications like ISO 9001 are not universally held among smaller exporters, evidence of quality management systems should be assessed through documented testing procedures and material traceability.

Production Capacity Verification

Evaluate supplier infrastructure using available indicators:

- Minimum factory area supporting dedicated assembly lines

- In-house machining capabilities for molds and structural components

- Monthly output capacity exceeding 50 units for sustained order fulfillment

Cross-reference online revenue metrics and delivery performance (target ≥85% on-time rate) to assess operational stability.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk. Prioritize suppliers offering sample units at incremental pricing, enabling functional validation prior to bulk purchase. Insist on post-delivery inspection rights and clarify warranty terms covering wear-prone parts like dies and levers.

What Are the Best Manual Block Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Linyi Fulang Machinery Co., Ltd. | Shandong, CN | Manual interlocking brick machines, earth soil compressors | $900–5,500 | 1 set | 83% | ≤2h | <15% | Color, size, logo, packaging, graphic labeling |

| Gongyi Chenghui Machinery Equipment Co., Ltd. | Henan, CN | No-electricity brick machines, manual laterite compressors | $500–870 | 1 set | 100% | ≤3h | <15% | Not specified |

| LONTA MACHINERY CO.,LTD | Henan, CN | Portable manual earth mud block makers | $770–950 | 1 set | 87% | ≤4h | <15% | Not specified |

| Changge Hengruide Machinery Equipment Co., Ltd. | Henan, CN | Household interlock paving block machines | $85–400 | 1 unit/piece | 100% | ≤1h | 16% | Not specified |

| Henan Kaigao Machinery Manufacturing Co., Ltd. | Henan, CN | Low-cost portable brick making machinery | $999 | 1 case | 100% | ≤1h | <15% | Not specified |

Performance Analysis

Gongyi Chenghui and Changge Hengruide stand out for perfect on-time delivery records and competitive pricing under $900, making them strong candidates for budget-conscious buyers seeking proven reliability. Linyi Fulang offers premium models up to $5,500 with extensive customization—ideal for branded deployments or region-specific adaptations. Despite higher base prices, its flexibility in color, labeling, and design integration provides strategic value for distributors. LONTA balances mid-range pricing with consistent output quality, particularly in mobile manual models suited for rural infrastructure projects. Henan Kaigao’s uniform $999 pricing suggests standardized packaging, possibly limiting configurability despite high responsiveness.

FAQs

What is the typical MOQ for manual block machines?

Most suppliers list a minimum order quantity of 1 set or unit, though some require multi-unit purchases (e.g., 4 pieces) for certain configurations. Case-based pricing may apply for consolidated shipments.

How long does production and shipping take?

Manufacturing lead time averages 20–30 days after order confirmation. International shipping via sea freight adds 25–40 days depending on destination. Air freight reduces transit to 5–10 days but increases costs significantly for heavy machinery.

Can I request custom molds or branding?

Yes, select suppliers like Linyi Fulang offer full customization including mold dimensions, paint color, logo embossing, and packaging design. Technical drawings or CAD files may be required for non-standard block shapes.

Are manual block machines suitable for commercial use?

Yes, especially models rated for 400–500 bricks per day. Machines from Gongyi Chenghui and LONTA are engineered for daily field deployment in low-infrastructure settings, requiring no external power source and minimal maintenance.

Do suppliers provide usage training or technical support?

Support varies by exporter. Some include instructional videos or manuals in English; others offer remote guidance upon request. Pre-purchase verification of after-sales communication channels is recommended, particularly for first-time buyers.