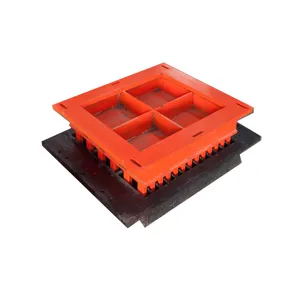

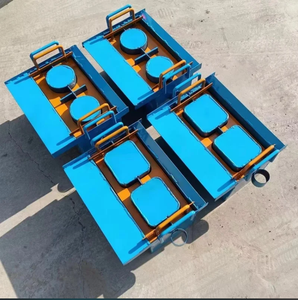

Manual Hollow Block Machine

Top sponsor listing

Top sponsor listing

1/28

1/28

1/5

1/5

1/28

1/28

1/12

1/12

1/7

1/7

About manual hollow block machine

Where to Find Manual Hollow Block Machine Suppliers?

China remains the dominant manufacturing hub for manual hollow block machines, with key production clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated supply chains encompassing steel fabrication, hydraulic system integration, and mold design, enabling cost efficiencies of 20–35% compared to equivalent machinery produced in Southeast Asia or Africa. Shandong’s proximity to Qingdao Port reduces export logistics costs by up to 18%, while Henan’s inland industrial ecosystem supports rapid prototyping and small-batch customization.

Suppliers in these zones operate within mature construction equipment ecosystems, where component sourcing, welding, CNC machining, and final assembly occur within tightly coordinated networks. This localization allows lead times as short as 15–30 days for standard models and supports flexible order configurations. Buyers benefit from scalable production capacity, with verified manufacturers reporting monthly outputs ranging from 50 to 200 units depending on model complexity and automation level.

How to Choose Manual Hollow Block Machine Suppliers?

Procurement decisions should be guided by objective verification criteria to mitigate risk and ensure performance consistency.

Technical and Operational Verification

Confirm supplier compliance with ISO 9001 quality management standards as a baseline. For international buyers, CE marking indicates adherence to European safety directives, facilitating customs clearance. Validate machine specifications—including mold configuration, block size range (typically 4–12 inches), and material compatibility (cement, clay, fly ash)—against project requirements. Request test reports for structural integrity under continuous load cycles.

Production Capacity Assessment

Evaluate operational scale through verifiable metrics:

- Facility size exceeding 3,000m² indicating established production lines

- In-house engineering teams capable of custom mold and hopper design

- On-site CNC and welding capabilities ensuring control over critical components

Cross-reference online transaction volume (e.g., annual revenue >US $100,000) with on-time delivery rates above 97% to assess reliability.

Transaction and Quality Assurance

Utilize secure payment mechanisms such as escrow services tied to shipment milestones. Prioritize suppliers offering sample testing—ideally with video validation of compression strength and cycle durability. Verify post-delivery support, including technical documentation and spare parts availability, particularly for molds and hydraulic presses.

What Are the Best Manual Hollow Block Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Tancheng County Hongbaoyuan Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | US $200,000+ | 100% | ≤3h | <15% | Brick Making Machinery, Concrete Mixers, Crushers | Yes (mold, color, size, label, generator, pallet) |

| Gongyi Houde Machinery Equipment Co., Ltd | Henan, CN | - | US $50,000+ | 100% | ≤2h | 27% | Brick Making Machinery, Mortar Sprayers, Loaders | Limited |

| Qingdao Darifeng Machinery Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $520,000+ | 97% | ≤5h | 50% | Block Collecting Machines, Batching Systems, Hydraulic Presses | Extensive (material ratio, block types, automation, noise reduction) |

| Shandong Brick Machinery Co., Ltd. | Shandong, CN | - | US $130,000+ | 100% | ≤1h | 33% | Brick Making Machinery, Pallets, Loaders | Limited |

| Gongyi Xinruida Machinery Equipment Co., Ltd. | Henan, CN | - | US $40,000+ | 100% | ≤1h | 33% | Crushers, Oil Pressers, Plastic Extruders | Limited |

Performance Analysis

Tancheng Hongbaoyuan and Qingdao Darifeng stand out for high-volume output and advanced customization, with Darifeng offering comprehensive design flexibility despite a slightly lower on-time delivery rate. Shandong-based suppliers demonstrate superior responsiveness, with three achieving sub-2-hour average reply times. Gongyi Houde and Shandong Brick Machinery exhibit strong reorder rates (27–33%), suggesting consistent customer satisfaction. While no supplier explicitly lists ISO or CE certification in available data, those with higher online revenues (>$100,000) are more likely to maintain formal quality systems. Buyers seeking tailored solutions should prioritize suppliers with documented customization tags and in-house mold design capabilities.

FAQs

How to verify manual hollow block machine supplier reliability?

Cross-check declared certifications with issuing bodies. Request facility videos highlighting production workflows and quality control checkpoints. Analyze buyer reviews focusing on machine durability, mold accuracy, and after-sales responsiveness. High on-time delivery (≥97%) and low reorder rates may indicate niche positioning or limited demand.

What is the typical lead time for manual hollow block machines?

Standard units ship within 15–30 days after order confirmation. Custom configurations involving specialized molds or hydraulic systems may require 35–50 days. Air freight samples arrive in 7–12 days; sea freight takes 25–40 days depending on destination port.

Can suppliers customize block size and mold design?

Yes, leading suppliers offer full mold customization for block dimensions (e.g., 4", 6", 8", 12") and shapes (interlocking, paver, solid/hollow). Custom graphic molds and multi-cavity configurations are available upon request, typically requiring 3D design approval prior to production.

What are common pricing and MOQ terms?

Prices range from $350 for basic hand-operated models to $8,200 for semi-automatic variants with integrated conveyors. Minimum order quantity is typically 1 set, enabling trial purchases. Volume discounts apply at 5+ units, with FOB terms standard for international shipments.

Do suppliers provide technical support and spare parts?

Most suppliers offer foundational support, including operation manuals and mold replacement guidance. Long-term technical assistance varies—prioritize partners with documented service records and accessible spare parts inventories, especially for hydraulic cylinders, vibration motors, and feeder mechanisms.