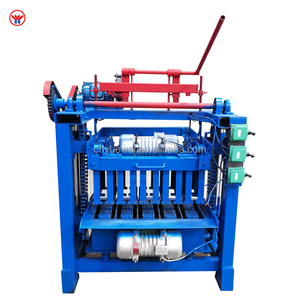

Manual Block Making Machine For Sale

Top sponsor listing

Top sponsor listing

1/12

1/12

1/17

1/17

1/12

1/12

1/14

1/14

1/16

1/16

1/5

1/5

1/15

1/15

1/26

1/26

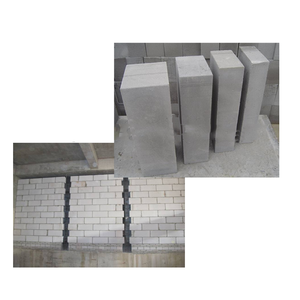

About manual block making machine for sale

Where to Find Manual Block Making Machine Suppliers?

China remains the central hub for manual block making machine production, with key manufacturing clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that combine raw material processing, casting, hydraulic system integration, and final assembly under one supply chain. Shandong, in particular, is home to established machinery exporters leveraging proximity to Qingdao Port for efficient global shipping, reducing logistics lead times by 10–15 days compared to inland regions.

The clustering effect enables cost efficiencies of 20–30% over non-specialized manufacturers due to localized access to steel, casting foundries, and component suppliers within a 50km radius. Factories in this sector typically operate on lean production models with monthly output capacities ranging from 50 to 300 units depending on automation level. Most suppliers support both standard configurations and buyer-specific modifications in mold design, block dimensions, and material feed systems, facilitating rapid scaling for regional construction projects.

How to Choose Manual Block Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional parameters:

Technical & Quality Compliance

Confirm adherence to ISO 9001 quality management standards as a baseline. For export markets in Europe or North America, CE marking indicates compliance with safety and environmental directives. Request documentation verifying testing procedures for structural integrity, hydraulic pressure tolerance (typically 10–16 MPa), and wear resistance of molds. Machines designed for continuous operation should include reinforced frames and heat-treated plungers.

Production Capability Verification

Assess infrastructure maturity through measurable indicators:

- Minimum factory area of 3,000m² to ensure dedicated production lines

- In-house capabilities in welding, CNC machining, and mold fabrication

- Presence of R&D or engineering teams for customization support

Cross-reference these with performance metrics such as on-time delivery rates (target ≥95%) and reorder frequency to gauge reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms like escrow services until post-delivery inspection is completed. Prioritize suppliers offering sample units for field testing—ideally producing at least 500 blocks per test cycle to evaluate consistency in density and dimensional accuracy. Review transaction history for dispute resolution patterns and after-sales responsiveness, particularly for spare parts availability.

What Are the Best Manual Block Making Machine Suppliers?

| Company Name | Location | Verified Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Custom Manufacturer | Brick Making Machinery, Tile Making Machinery, Concrete Mixers | US $390,000+ | 100% | ≤2h | 66% | $180–$2,700 |

| Zhengzhou Canmax Machinery&equipment Co., Ltd. | Henan, CN | Multispecialty Supplier | Brick Making Machinery, Hydraulic Press Systems | US $320,000+ | 100% | ≤3h | 31% | $180–$100,000 |

| Shandong Brick Machinery Co., Ltd. | Shandong, CN | Not Specified | Brick Making Machinery, Pallets, Loaders | US $140,000+ | 100% | ≤1h | 30% | $1,500–$2,700 |

| Gongyi Chenghui Machinery Equipment Co., Ltd. | Henan, CN | Not Specified | Brick Making Machinery, Crushers, Sand Makers | US $60,000+ | 100% | ≤3h | 20% | $400–$880 |

| LONTA MACHINERY CO.,LTD | Henan, CN | Not Specified | Concrete Mixers, Compactors, Brick Machines | US $40,000+ | 87% | ≤3h | <15% | $770–$950 |

Performance Analysis

Shandong Hongfa stands out with the highest reorder rate (66%) and broadest customization scope, including diesel-powered hydraulic stations, color configuration options, and hollow/solid block conversion kits. Its integration of conveyors and silo systems suggests capability for semi-automated line expansion. Zhengzhou Canmax offers extreme price flexibility—from compact manual presses at $180 to full-scale setups exceeding $100,000—indicating scalability for diverse project budgets. Shandong Brick Machinery demonstrates strong technical responsiveness (≤1h average reply time), advantageous for iterative design discussions.

While all top-tier suppliers maintain 100% on-time delivery except LONTA (87%), lower reorder rates (<15–20%) may signal gaps in after-sales service or inconsistent build quality. Buyers should request product videos, third-party inspection reports, and client references before large-volume commitments.

FAQs

What materials are compatible with manual block making machines?

Most machines process cement-based mixes with aggregates like sand, fly ash, slag, or crushed stone. Some models support compressed earth blocks (CEB) using stabilized soil. Verify compatibility with local raw materials, especially if aiming for eco-construction or low-carbon applications.

What is the typical MOQ and lead time?

Standard minimum order quantity is 1 set, allowing pilot testing. Lead times range from 15 to 30 days for ready-to-ship units; customized models require 35–45 days depending on mold complexity and hydraulic system configuration.

Can I customize mold shapes and block dimensions?

Yes, nearly all listed suppliers offer mold customization for interlocking, paver, hollow, or solid block profiles. Common sizes include 4", 6", 8", and 9.6" widths. Provide CAD drawings or physical samples to initiate tooling development, typically completed within 10–14 days.

Do suppliers provide technical training or installation support?

Support varies: some offer remote guidance via video, while others provide on-site technician deployment at additional cost. Confirm inclusion of operation manuals, maintenance schedules, and spare part lists (especially seals, molds, and plungers) prior to shipment.

How are machines packaged and shipped internationally?

Machines are generally exported in plywood crates or iron pallets suitable for container loading. FOB terms are common; buyers arrange final freight. Full sets fit in 20ft or 40ft containers depending on auxiliary equipment (e.g., mixers, conveyors). Sea freight is standard; air shipping is viable only for compact models under 500kg.