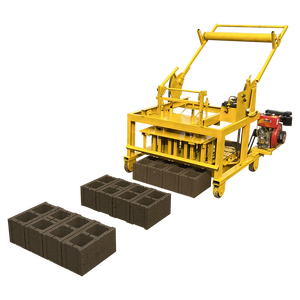

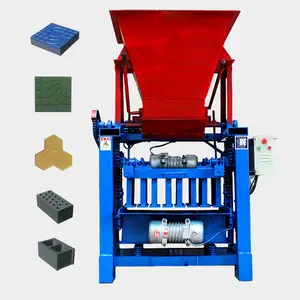

Manual Concrete Block Making Machine For Sale

1/17

1/17

1/28

1/28

1/12

1/12

1/25

1/25

1/17

1/17

CN

CN

1/29

1/29

1/5

1/5

1/14

1/14

About manual concrete block making machine for sale

Where to Find Manual Concrete Block Making Machine Suppliers?

China remains the dominant hub for manual concrete block making machine production, with key manufacturing clusters in Henan, Shandong, and Hebei provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable output, enabling competitive pricing and consistent quality control. Henan and Shandong alone account for over 70% of China’s brick and block machinery exporters, leveraging regional advantages such as proximity to steel foundries, established logistics corridors, and specialized labor pools.

Suppliers in these zones operate within tightly networked industrial ecosystems where raw material sourcing, component fabrication, and final assembly occur within concentrated geographic radii. This integration reduces lead times by up to 30% compared to decentralized production models. Buyers benefit from MOQs as low as one unit, with standard delivery windows ranging from 15 to 30 days for non-customized models. The presence of dedicated R&D departments at leading firms enables adaptation to regional construction standards, including interlock design, compression strength requirements, and mold configurations.

How to Choose Manual Concrete Block Making Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international quality management systems such as ISO 9001. While not all suppliers list CE or similar certifications explicitly, ensure documentation is available upon request—particularly for hydraulic components, structural welds, and load-bearing frames. Request test reports on material durability, including tensile strength of steel molds and wear resistance under repeated compaction cycles.

Production Capability Assessment

Evaluate supplier infrastructure using measurable benchmarks:

- Facility size exceeding 2,000m² indicates capacity for batch production

- In-house mold design and CNC machining capabilities enhance customization precision

- Demonstrated reorder rates above 25% reflect customer satisfaction and product reliability

Cross-reference online revenue indicators and on-time delivery performance (target ≥97%) to assess operational stability.

Customization and After-Sales Support

Confirm availability of tailored solutions such as adjustable mold sizes, ergonomic handling features, or mobile frame designs. Leading suppliers offer digital support through CAD drawings, video demonstrations, and remote troubleshooting. Prioritize partners providing user manuals in English and accessible technical training resources.

Transaction Security Measures

Utilize secure payment methods with escrow functionality to mitigate risk. Review supplier response times (ideally ≤2 hours) and dispute resolution history. Conduct sample testing before full procurement—evaluate block consistency, demolding ease, and machine ergonomics under real-world conditions.

What Are the Best Manual Concrete Block Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | MOQ |

|---|---|---|---|---|---|---|---|---|

| Changge Hengruide Machinery Equipment Co., Ltd. | Henan, CN | Other Construction Machinery, Power Trowel, Crusher | US $10,000+ | 100% | ≤1h | 16% | $75–800 | 1 piece/unit |

| Gongyi Houde Machinery Equipment Co., Ltd | Henan, CN | Brick Making Machinery, Concrete Mixers, Excavators | US $50,000+ | 100% | ≤2h | 27% | $160–2,400 | 1 set |

| Shandong Kaiqian Intelligent Equipment Co., Ltd. | Shandong, CN | Customizable Block Machines, Conveyor Systems | US $90,000+ | 100% | ≤2h | 50% | $800–2,990 | 1 set |

| Hebei Zhongke Jiantong Machinery Equipment Co., Ltd. | Hebei, CN | Brick Making Machinery, Wood Crushers, Concrete Pumps | US $80,000+ | 100% | ≤4h | <15% | $289–823 | 1 set |

| Qingdao Darifeng Machinery Co., Ltd. | Shandong, CN | Hydraulic Presses, Batching Equipment, Brick Molds | US $500,000+ | 97% | ≤5h | 54% | $800–3,000 | 1 set |

Performance Analysis

Qingdao Darifeng stands out with the highest verified online revenue (US $500,000+) and a 54% reorder rate, indicating strong market trust and repeat business. Despite a slightly longer average response time, its extensive customization options—including pallet size, vibration frequency, and automation level—make it ideal for buyers requiring engineered-to-order solutions. Shandong Kaiqian follows closely with a 50% reorder rate and full on-time delivery record, supported by advanced configuration tools for block type, mold design, and output capacity.

Henan-based Gongyi Houde offers mid-range pricing and solid service metrics, catering well to small-scale contractors seeking reliable entry-level machines. Changge Hengruide provides the lowest starting price point ($75), suitable for household or micro-enterprise use, though its lower reorder rate suggests limited post-purchase engagement. Hebei Zhongke targets niche export markets with standardized hollow block models but lags in responsiveness and customer retention.

FAQs

What is the typical MOQ for manual concrete block making machines?

Most suppliers offer a minimum order quantity of 1 unit or set, facilitating trial purchases and small-scale deployment. Bulk orders often unlock incremental discounts and extended warranty terms.

How long does production and shipping take?

Standard units are typically manufactured within 10–15 days after order confirmation. Sea freight to international destinations adds 20–35 days depending on port location. Air shipping reduces transit time to 5–10 days but increases costs significantly.

Can I customize the mold design for specific block types?

Yes, many suppliers offer customizable molds for interlocking, hollow, solid, or paving blocks. Custom tooling may require additional lead time (7–14 days) and NRE fees, which are often waived upon placement of larger orders.

Do suppliers provide operation manuals and training?

Reputable manufacturers supply detailed user guides in English and may offer video tutorials or remote guidance. Some provide on-site training for large contracts or turnkey installations.

Are spare parts readily available?

Leading suppliers maintain inventories of critical wear components such as seals, pins, and mold plates. Confirm spare part pricing and availability before purchase to minimize future downtime.