Machine For Making Chips

Top sponsor listing

Top sponsor listing

CN

CN

1/17

1/17

CN

CN

1/16

1/16

1/2

1/2

1/9

1/9

1/29

1/29

About machine for making chips

Where to Find Chip Making Machine Suppliers?

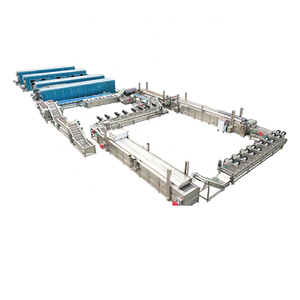

China leads global manufacturing of chip processing equipment, with concentrated industrial hubs in Shandong, Jiangsu, and Guangdong provinces offering specialized capabilities. Shandong is home to a high density of food processing machinery manufacturers, particularly around Jinan and Qingdao, where vertically integrated supply chains for stainless steel components and automated control systems reduce production lead times by 20–30%. Jiangsu-based suppliers, including those in Changzhou, focus on energy-efficient freezing and frying integration lines, leveraging proximity to advanced refrigeration technology clusters.

These regional ecosystems enable rapid prototyping and scalable production, supported by localized networks of CNC machining workshops, conveyor system fabricators, and PLC programming specialists within 50km radii. Buyers benefit from shorter delivery cycles (typically 30–45 days for standard configurations), 15–25% lower unit costs compared to Western suppliers, and strong flexibility for both turnkey production lines and modular upgrades. The presence of mature export logistics infrastructure further enhances reliability for international procurement.

How to Choose Chip Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compatibility, operational reliability, and transaction security.

Technical Compliance & Certification

Verify adherence to internationally recognized standards such as ISO 9001 for quality management and CE marking for electrical and mechanical safety compliance. For exports to EU or North American markets, confirm conformity with local food safety regulations (e.g., FDA-compliant materials). Equipment contacting food must use SUS304 or SUS316 stainless steel; request mill test certificates for material verification.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² to support full-line assembly

- In-house engineering teams capable of customizing line speed, voltage, and automation level

- Integrated testing facilities for frying temperature stability, slicing precision, and dehydration efficiency

Cross-reference online performance metrics—on-time delivery ≥95%, response time ≤3 hours—with product listing consistency and update frequency.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services that release funds only after shipment confirmation. Prioritize suppliers with documented after-sales service frameworks, including remote diagnostics, spare parts availability, and operator training. Pre-shipment inspection protocols should include functional testing under load conditions and validation of motor, heater, and conveyor performance.

What Are the Best Chip Making Machine Suppliers?

| Company Name | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Verification Status |

|---|---|---|---|---|---|---|---|---|

| Dongguan ICT Technology Co., Ltd. | Electronics Production Machinery, Soldering Machines, SMT Solutions | Color, material, size, logo, packaging, panel graphics, stencil design | US $350,000+ | 100% | ≤3h | 100% | 15+ models | Multispecialty Supplier |

| Changzhou Zhongxue Refrigeration Equipment Co., Ltd. | Potato Chips Production Lines, Frozen French Fry Systems | Color, material, size, logo, packaging, label, graphic | US $10,000+ | 100% | ≤1h | 50% | 5 models | Custom Manufacturer |

| Shandong Shengkang Shengshi Intelligent Equipment Machinery Co., Ltd. | Potato Chips Making Machine, Food Processing Lines, Fryers | Limited customization per listings | US $30,000+ | 100% | ≤1h | - | 5 models | Unverified |

| FENG LIAN DA MACHINERY CO LTD | Crispy Chips, Bugles, Puff Snack, Corn Chips Machinery | No explicit customization noted | - | - | ≤1h | - | 5 models | Unverified |

| GELGOOG CO., LTD | Banana Chips, Plantain Chips, Automatic Fryer Lines | No customization indicated | - | - | ≤1h | - | 5 models | Unverified |

Performance Analysis

Dongguan ICT Technology stands out with a 100% reorder rate and extensive customization options across color, material, and branding elements, indicating high client retention and flexible engineering capacity. Changzhou Zhongxue demonstrates superior responsiveness (≤1h) and proven capability in fully automatic frozen fry lines, with pricing ranging up to $72,000 for eco-stainless configurations. Shandong Shengkang offers competitive high-capacity systems (up to 1,000kg/h), backed by consistent on-time delivery records. While several suppliers lack reorder rate data, their active product portfolios suggest ongoing market engagement. For mission-critical deployments, prioritize verified suppliers with transparent revenue reporting and multi-point customization support.

FAQs

How to verify chip making machine supplier reliability?

Validate certifications through official databases and request third-party audit reports covering fabrication processes and quality control checkpoints. Assess operational transparency via facility videos, equipment testing footage, and verifiable customer references focusing on post-installation support and uptime performance.

What is the average lead time for chip production lines?

Standard configurations typically ship within 30–45 days after order confirmation. Customized or high-capacity systems (e.g., 1,000kg/h fully automatic lines) may require 50–60 days for fabrication and pre-shipment testing. Air freight reduces transit time to 5–7 days; sea freight averages 20–35 days depending on destination port.

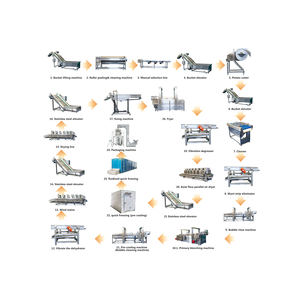

Can suppliers provide customized chip processing solutions?

Yes, leading manufacturers offer tailored engineering for output capacity, raw material type (potato, banana, plantain, sweet potato), power specifications, and automation level. Verified suppliers with R&D teams can modify slicing thickness (1–5mm), frying duration, and dehydration settings to meet regional taste and texture requirements.

Do suppliers offer sample machines or pilot lines?

Sample policies vary. Some suppliers provide scaled-down demo units for process validation at partial cost recovery (30–50% of unit price). Full pilot lines are generally available only for qualified buyers committing to volume orders. Request video demonstrations and batch test results if physical sampling is not feasible.

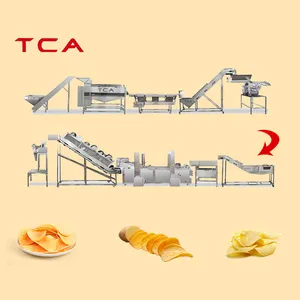

What are typical MOQ and pricing structures?

Minimum Order Quantity is typically 1 set, allowing small-scale testing. Entry-level semi-automatic lines start at $2,000, while fully automated industrial systems range from $8,000 to over $70,000 depending on capacity and integration level. Bulk orders (3+ sets) often qualify for negotiated discounts and extended warranty terms.