Make To Stock Product Examples

CN

CN

1/28

1/28

1/24

1/24

1/22

1/22

About make to stock product examples

Where to Find Make-to-Stock Product Suppliers?

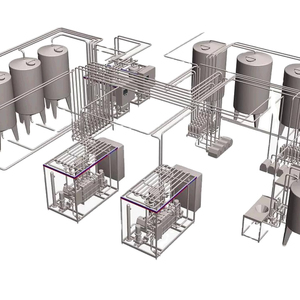

China remains a dominant force in the production of make-to-stock (MTS) industrial systems and equipment, with key manufacturing clusters located in Henan, Guangdong, and Hebei provinces. These regions host vertically integrated facilities capable of delivering standardized machinery and pre-fabricated solutions at scale. Henan specializes in food processing and chemical equipment, leveraging localized R&D hubs and cost-efficient labor pools. Guangdong’s Pearl River Delta excels in consumer goods manufacturing, particularly fragrance and home care products, supported by advanced packaging and formulation technologies. Hebei and Jiangsu lead in structural steel and welding machinery, benefiting from proximity to raw material sources and heavy industry zones.

The concentration of suppliers in these areas enables streamlined sourcing through consolidated supply chains, reducing component procurement time by up to 40%. Buyers gain access to mature ecosystems where design, fabrication, testing, and logistics are co-located, ensuring faster turnaround for standard configurations. Typical advantages include MOQ flexibility (from single sets to bulk orders), lead times averaging 20–45 days for production lines, and competitive pricing driven by economies of scale. This infrastructure supports both off-the-shelf availability and light customization without compromising delivery timelines.

How to Choose Make-to-Stock Product Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Production Infrastructure Assessment

Verify that suppliers operate dedicated production lines rather than relying on subcontractors. Key indicators include facility size, in-house engineering teams, and ownership of core processing equipment such as CNC machines, automated mixers, or structural assembly units. Prioritize companies with documented monthly output capacity and investment in quality control instrumentation.

Quality and Compliance Verification

While formal certifications (e.g., ISO 9001, CE) may not always be listed, consistent on-time delivery rates above 97% and responsive communication (≤4 hours average response time) serve as proxies for operational discipline. For export-bound equipment, confirm compatibility with destination-market safety and electrical standards. In consumer goods sectors like fragrances, ensure compliance with labeling regulations and volatile organic compound (VOC) limits.

Order Flexibility and Customization Support

Evaluate suppliers based on their ability to accommodate branding, dimensional adjustments, or functional modifications. Many MTS suppliers offer OEM services including logo printing, color variation, and packaging redesign—particularly prevalent in fragrance diffusers and food processing lines. Confirm whether customization impacts lead time or minimum order thresholds.

Transaction Security and After-Sales Capability

Favor suppliers with verifiable online transaction histories and participation in secure payment frameworks. Analyze reorder rates as an indicator of customer satisfaction—rates exceeding 15% suggest dependable performance. Request references or case studies for large-scale installations, especially for capital-intensive systems such as juice plants or steel structure production lines.

What Are the Best Make-to-Stock Product Suppliers?

| Company Name | Main Products | Price Range (Min. Order) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Wuxi Zhouxiang Complete Set Of Welding Equipment Co., Ltd. | Metal Product Processing Line, Welding Equipment | $57,000–150,000 (1 set) | 100% | ≤4h | - | US $4,000+ | Not specified |

| Zhengzhou Sunshine Machinery Equipment Co., Ltd. | Soap Making Machines, Chemical Equipment | $2,000–9,000 (1 set) | 100% | ≤1h | <15% | US $50,000+ | Not specified |

| Guangzhou Amos Fragrance Technology Co., Ltd. | Reed Diffusers, Scented Candles, Air Fresheners | $1.90–4.60 (300 pcs) | 100% | ≤2h | 16% | US $30,000+ | Logo, packaging, label, graphic |

| Zhengzhou Youding Trade Co., Ltd. | Peanut Butter Lines, Juice Processing Plants | $750–80,000 (1 set) | 100% | ≤1h | <15% | US $40,000+ | Color, material, size, logo, packaging |

| Hebei Baofeng Steel Structure Co., Ltd. | Steel Structure Buildings, Workshops, Prefab Houses | $25.99–45.99/sqm (1,000 sq cm) | 100% | ≤9h | - | - | Free design support |

Performance Analysis

All five suppliers demonstrate perfect on-time delivery records, indicating strong production planning and execution capabilities. Zhengzhou Sunshine Machinery and Zhengzhou Youding Trade stand out for sub-1-hour average response times, reflecting high engagement levels suitable for urgent procurement cycles. Guangzhou Amos achieves a 16% reorder rate—above industry baseline—suggesting effective product quality and service consistency in the competitive fragrance sector. Wuxi Zhouxiang and Hebei Baofeng focus on high-value industrial systems, with entry points starting above $57,000, targeting mid-to-large enterprises requiring turnkey installations. Hebei Baofeng offers one of the lowest per-unit pricing models ($25.99/m²), ideal for scalable construction projects. Zhengzhou-based suppliers dominate responsiveness and diversified processing line offerings, making them strategic partners for food and chemical equipment sourcing.

FAQs

What defines a true make-to-stock product in industrial sourcing?

A make-to-stock product is manufactured in advance based on forecasted demand rather than custom specifications. These items are typically standardized, available for immediate or short-lead-time delivery, and sold in predefined configurations. Examples include soap production lines, steel structure workshops, and reed diffuser kits offered at fixed price points with minimal setup delay.

What are common MOQs for MTS industrial equipment?

For machinery, the minimum order quantity is often "1 set," allowing buyers to procure complete production lines without volume commitments. In packaged consumer goods like air fresheners, MOQs range from 2 to 300 pieces depending on packaging type. Lower MOQs facilitate sampling and market testing before full rollout.

How long are typical lead times for MTS systems?

Standard delivery windows range from 15 to 45 days post-payment confirmation. Simpler systems (e.g., small soap machines) ship within 15–25 days, while complex setups like juice factories or H-beam production lines require 30–45 days due to assembly and testing requirements.

Can make-to-stock products be customized?

Yes, many suppliers offer limited customization even under MTS models. Common options include logo imprinting, color selection, voltage adaptation, and minor dimensional adjustments. Full engineering changes may transition the order into a make-to-order framework with revised timelines and pricing.

Are samples available for make-to-stock products?

Sample availability depends on product type. For consumables like scented oils or diffusers, physical samples are commonly provided upon request. For machinery, digital renderings, operation videos, or factory test runs serve as alternatives. Some suppliers waive sample fees for subsequent bulk orders.