Makino 5 Axis Cnc Machine

1/20

1/20

1/15

1/15

1/11

1/11

1/9

1/9

1/9

1/9

CN

CN

1/3

1/3

1/7

1/7

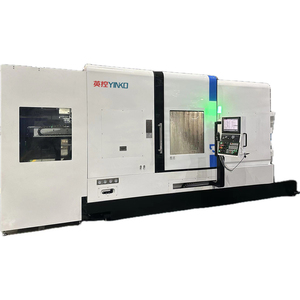

About makino 5 axis cnc machine

Where to Find Makino 5-Axis CNC Machine Suppliers?

China remains a dominant force in the production of high-precision 5-axis CNC machining equipment, with key manufacturing clusters concentrated in Jiangsu, Shandong, and Zhejiang provinces. These regions host vertically integrated facilities capable of producing industrial-grade machines that emulate the performance characteristics of premium brands like Makino. Jiangsu and Shandong, in particular, are home to specialized machine tool manufacturers leveraging local supply chains for cast iron bases, linear guides, and spindle assemblies—reducing component procurement time by up to 30% compared to offshore alternatives.

The ecosystem supports both standardized and semi-custom configurations, with suppliers offering full vertical integration from structural casting to final calibration. Proximity to ports such as Qingdao, Shanghai, and Ningbo enables efficient export logistics, with average lead times ranging from 25–45 days for standard units. Buyers benefit from localized sourcing of critical subsystems—including Taiwan-sourced ball screws and Japanese or German CNC controls—allowing competitive pricing while maintaining mechanical rigidity and positioning accuracy within ±0.005mm.

How to Choose Makino 5-Axis CNC Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers possess in-house design and assembly capabilities for multi-axis kinematics. Essential components include high-speed spindles (≥24,000 rpm), tilt-rotary tables, and FANUC, Siemens, or Mitsubishi control systems. Request documentation on dynamic balancing tests, thermal growth compensation, and backlash measurement protocols. Machines marketed as “Makino-style” should demonstrate comparable rigidity through finite element analysis (FEA) reports and cutting trial videos.

Production Infrastructure Assessment

Evaluate the following benchmarks during supplier audits:

- Minimum factory area exceeding 3,000m² to support machining center assembly lines

- In-house gantry milling and precision scraping operations for bed flatness correction

- Dedicated quality inspection zone equipped with laser interferometers and ballbar testers

Cross-reference delivery performance data: prioritize suppliers with ≥97% on-time shipment rates and response times under 3 hours.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow or letter of credit (LC) terms. Insist on pre-shipment inspections (PSI) conducted either independently or via third-party services. Sample validation is strongly advised—request test cuts using customer-specific materials (e.g., titanium, Inconel) to verify surface finish and dimensional repeatability before committing to bulk orders.

What Are the Best Makino 5-Axis CNC Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) | Key Product Lines |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Hoston Machine Tools Co., Ltd. | Jiangsu, CN | $570,000+ | 100% | ≤3h | 75% | Yes (color, material, logo, packaging) | $2,500–$32,500 | 5-Axis Vertical Machining Centers, CNC Milling Machines |

| Shandong Mainland Cnc Equipment Co., Ltd. | Shandong, CN | $180,000+ | 100% | ≤3h | 25% | No explicit mention | $13,194–$32,200 | VMC Series, 3/4/5-Axis Machining Centers |

| Linyi Chaoda International Cnc Technology Co., Ltd. | Shandong, CN | $50,000+ | 100% | ≤11h | 50% | No explicit mention | $10–$1,111,111 | Wood & Stone Routers, Foam/Glass CNC Systems |

| Zaozhuang Shenghuan CNC Machine Tool Co., Ltd. | Shandong, CN | $4,000+ | Not reported | ≤2h | <15% | No explicit mention | $10,500–$30,180 | High-Speed 5-Axis VMC, CNC Lathes, EDM |

| Ningbo Kaibo CNC Machinery Co., Ltd. | Zhejiang, CN | Not reported | 100% | ≤16h | Not reported | No explicit mention | $13,000–$42,000 | 5-Axis Molding Machines, Shoe Last & Wood Carving Systems |

Performance Analysis

Jiangsu Hoston stands out with the highest reorder rate (75%) and robust customization capacity, indicating strong buyer satisfaction and flexible manufacturing execution. Despite listing one anomalously low-priced product ($10), Linyi Chaoda demonstrates niche expertise in non-metallic material processing, supported by a 50% reorder rate. Shandong-based suppliers exhibit consistent on-time delivery (100%), though lower reorder rates suggest room for improvement in post-sale service or long-term reliability.

Zaozhuang Shenghuan offers aggressive pricing but lacks verifiable reorder metrics and on-time delivery confirmation, presenting higher procurement risk. Ningbo Kaibo covers specialized applications such as mold and footwear machining, with documented 100% delivery compliance despite slower response cycles. For general-purpose 5-axis milling resembling Makino platforms, Jiangsu and Shandong suppliers provide the most balanced combination of cost efficiency, technical readiness, and export experience.

FAQs

How to verify Makino 5-axis CNC machine supplier reliability?

Validate ISO 9001 certification status and request evidence of CE marking for electrical systems. Conduct virtual or physical factory audits to confirm spindle runout testing, axis alignment procedures, and vibration damping measures. Analyze transaction history for dispute resolution patterns and after-sales technical support responsiveness.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity (MOQ) of 1 set. Standard lead time ranges from 30 to 45 days post-deposit, depending on customization level. Expedited builds may be available for an additional fee, reducing delivery to 20–25 days for stock configurations.

Do suppliers offer customization options?

Yes, select manufacturers like Jiangsu Hoston provide customization in machine color, material feed systems, control panel layout, and branding elements (logo, labels). Advanced modifications—including specialized coolant delivery, probing systems, or automation interfaces—require direct engineering consultation and may extend lead time by 10–15 days.

Can these machines replicate Makino’s performance?

While not original Makino equipment, several suppliers engineer machines with similar structural designs, rotary table integration, and control compatibility. Performance parity depends on build quality, component selection (e.g., THK/Igus bearings, Heidenhain encoders), and calibration rigor. Independent benchmarking against ISO 230-2 standards is recommended for critical applications.

Are global shipments supported?

Yes, all listed suppliers have international sales experience. Confirm Incoterms (FOB, CIF, DAP) upfront and ensure compliance with destination country regulations regarding voltage, safety guards, and electromagnetic compatibility (EMC). Sea freight is standard for full-container loads; air shipping is feasible only for disassembled critical components due to size and weight constraints.