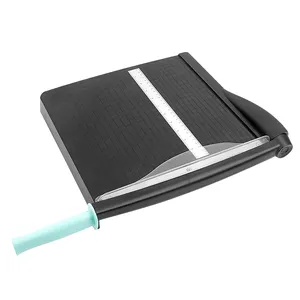

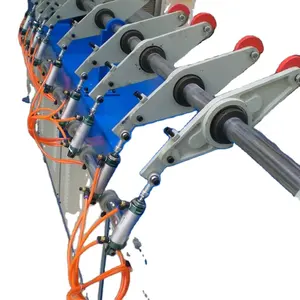

Manual Paper Core Cutting Machine

About manual paper core cutting machine

Where to Find Manual Paper Core Cutting Machine Suppliers?

China remains the central hub for manual paper core cutting machine manufacturing, with key production clusters in Zhejiang and Henan provinces. Hangzhou in Zhejiang Province hosts a dense concentration of office equipment and paper processing machinery suppliers, supported by mature supply chains for precision components like blades, rollers, and alignment guides. Zhengzhou in Henan serves as an industrial base for heavier-duty paper tube and core processing systems, offering cost efficiencies through localized steel and motor sourcing.

These regional ecosystems enable vertically integrated production—spanning raw material processing, CNC machining, assembly, and packaging—within compact geographic radii. This integration supports rapid prototyping and scalable output, with typical lead times ranging from 15 to 30 days for standard configurations. Buyers benefit from 20–35% lower unit costs compared to equivalent machinery produced in Southeast Asia or Europe, driven by high labor efficiency and component availability. The sector is characterized by strong customization capacity, particularly in blade geometry, roll size compatibility, and ergonomic design features.

How to Choose Manual Paper Core Cutting Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Management Verification

While formal certifications such as ISO 9001 are not universally declared in available data, prioritize suppliers demonstrating consistent on-time delivery rates (≥97%) and documented quality control processes. Response time under 3 hours and reorder rates above 30% indicate reliable service and product satisfaction. Confirm adherence to international safety standards for hand-operated machinery, especially edge protection and blade shielding mechanisms.

Production Capability Assessment

Evaluate suppliers based on observable indicators of scale and specialization:

- Suppliers listing over 200 dedicated paper processing machinery SKUs demonstrate focused expertise

- In-house capabilities in die-cutting, blade sharpening, and mechanical calibration enhance consistency

- Customization options for core diameter, material thickness (typically 0.1–5mm), and cutting length signal engineering flexibility

Cross-reference online revenue metrics (e.g., US $1.6M+ annual volume) with product range breadth to assess operational maturity.

Procurement Safeguards

Implement risk mitigation strategies including third-party inspection services prior to shipment. Utilize secure payment frameworks that release funds upon verification of product specifications. Request physical or digital samples to validate cut precision, handle durability, and material feed stability before placing bulk orders. Confirm packaging methods to prevent transit damage, particularly for machines with calibrated alignment systems.

What Are the Best Manual Paper Core Cutting Machine Suppliers?

| Company Name | Location | Main Product Focus | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Fuyang Sigo Office Supplies Co., Ltd. | Zhejiang, CN | Paper Processing Machinery (2,580 listings) | US $1,600,000+ | 98% | ≤2h | 16% | 1 unit | Yes |

| Hangzhou Caide Office Equipment Co., Ltd. | Zhejiang, CN | Office & Paper Cutters; Custom Design Options | US $380,000+ | 98% | ≤3h | <15% | 1 piece / 100 pieces | Yes |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Industrial Tube & Core Processing | US $390,000+ | 97% | ≤2h | 30% | 1 set | Yes |

| Yiwu Tonghe Imp. & Exp. Trading Firm | Zhejiang, CN | Paper & Leather Processing Machinery | US $20,000+ | 94% | ≤6h | <15% | 1 set | Limited |

| Shenzhen JCD Machinery Co., Ltd. | Guangdong, CN | Semi-Automatic & Manual Cutting Systems | Data Unavailable | 100% | ≤6h | No Data | 1–2 sets | Basic |

Performance Analysis

Hangzhou-based suppliers excel in low-MOQ accessibility and customization depth, with Hangzhou Fuyang Sigo leading in sales volume and product variety. Their offerings cater well to small businesses and distributors requiring flexible ordering. Zhengzhou Yize Machinery stands out for higher reorder rates (30%), suggesting strong customer retention despite larger minimum orders, likely due to robust industrial build quality. Shenzhen JCD achieves perfect on-time delivery performance but operates with less transparent financial metrics and higher entry thresholds. Buyers seeking rapid sampling and single-unit trials should prioritize Zhejiang-based vendors, while those needing durable, high-throughput models may consider Henan’s industrial-grade manufacturers.

FAQs

What is the typical MOQ for manual paper core cutting machines?

Minimum order quantities vary significantly: some suppliers offer single-unit purchases (e.g., $50–$75/unit), ideal for testing or retail distribution. Others require 100-piece lots or full sets, particularly for customized or industrial models priced above $1,500.

How long does it take to receive a sample?

Sample production typically takes 7–15 days, with shipping adding 5–10 days via express courier. Suppliers with in-stock components can dispatch within 48 hours. For modified designs, expect 2–3 weeks for adjustments and validation.

Can these machines handle different paper core diameters and thicknesses?

Yes, most models support adjustable clamping systems for core diameters ranging from 20mm to 150mm and material thicknesses between 0.1mm and 5mm. Custom tooling can be requested for non-standard sizes, especially for corrugated board or composite paper cores.

Do suppliers provide technical documentation and user manuals?

Reputable suppliers include operation guides, maintenance schedules, and blade replacement instructions in English. For compliance-critical markets, request CE-marking documentation or machine safety reports covering pinch points and blade guards.

Is customization available for branding or functional upgrades?

Many suppliers offer OEM labeling, color variation, and graphic imprinting. Functional modifications include enhanced blade materials (tungsten-carbide edges), swivel bases, measurement scales, and extended feed trays. Engineering feasibility should be confirmed before order placement.