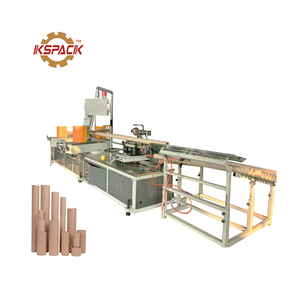

Paper Core Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

About paper core making machine

Where to Find Paper Core Making Machine Suppliers?

China remains the central hub for paper core making machine manufacturing, with key industrial clusters in Zhejiang, Henan, and Shandong provinces driving production efficiency and export capacity. Wenzhou in Zhejiang specializes in precision paper processing machinery, leveraging decades of engineering expertise in automation and die-cutting systems. Zhengzhou in Henan has emerged as a cost-competitive manufacturing base, supported by regional logistics advantages and vertically integrated supply chains for motors, rollers, and control systems.

These regions offer concentrated ecosystems where component sourcing, fabrication, and final assembly occur within tightly coordinated networks. This integration enables lead times averaging 20–35 days for standard configurations, with production scalability supported by facilities ranging from 4,000 to over 25,000 m². Localization reduces material procurement costs by 18–25% compared to non-Asian suppliers, particularly for steel frames, pneumatic components, and PLC control units. Buyers benefit from flexible MOQs—some suppliers accept single-unit orders—while maintaining compliance with international packaging and industrial safety standards.

How to Choose Paper Core Making Machine Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify ISO 9001 certification as a baseline indicator of quality management. For markets requiring regulatory alignment, confirm CE marking or equivalent declarations covering electrical safety (IEC 60204) and mechanical design (ISO 12100). Request test reports on critical subsystems such as glue application uniformity, winding tension control, and cutter blade durability.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Facility size exceeding 4,000m² indicating volume production capacity

- In-house R&D teams capable of adapting machine parameters (core diameter: 10–300mm; width: up to 1,600mm)

- Integrated machining capabilities including CNC lathing, welding, and automated assembly lines

Cross-reference online revenue data and order fulfillment history—suppliers with 100% on-time delivery rates demonstrate consistent operational performance.

Customization & Process Flexibility

Confirm the ability to process diverse materials: kraft paper, label stock, corrugated board, and composite layers. Leading suppliers support customization of inner diameter, length (up to 3,000mm), wall thickness, and adhesive type (hot melt, water-based). Mold/tooling modification services should be available for brand-specific labeling or structural reinforcement.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party payment protection and post-delivery commissioning assistance. Analyze reorder rates as a proxy for customer satisfaction—values above 30% indicate strong reliability and service quality. On-site technician training and remote troubleshooting via video guidance are essential for minimizing downtime during startup phases.

What Are the Best Paper Core Making Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Key Customization Options |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Chuangfeng Machinery Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $680,000+ | 100% | ≤2h | 33% | Paper Tube, Bobbin, Straw Machines | Kraft paper, color printing, diameter/length, logo embossing, mold design |

| Xingtai Mintai Machinery Manufacturing Co., Ltd. | Hebei, CN | - | US $20,000+ | 100% | ≤5h | <15% | Paper Processing, Packaging Lines | Cutter configurations, tube sizing, motor power options |

| Qingdao YiDaFa International Trade Co., Ltd. | Shandong, CN | Multispecialty Supplier | - | 100% | ≤2h | - | Automatic, High-Speed Tube Makers | Material thickness, conical cores, waste wood capacity, graphic printing |

| Zhengzhou JYD Machine Co., Ltd. | Henan, CN | Custom Manufacturer | US $410,000+ | 100% | ≤4h | 25% | Fully Automatic, Precision Cutters | Diameter, mold design, pulping line integration, water consumption optimization |

| Henan Mayjoy Mechanical Equipment Co., Ltd. | Henan, CN | Multispecialty Supplier | US $260,000+ | 91% | ≤4h | 45% | Manual & High-Speed Models | Paper width, rewinding systems, jumbo roll handling, sealing mechanisms |

Performance Analysis

Wenzhou Chuangfeng stands out with high online revenue and robust customization capabilities, particularly in specialty bobbins and straw cores. Zhengzhou JYD offers advanced automation with pricing aligned to mid-tier industrial budgets ($7,000–$24,000). Henan Mayjoy demonstrates exceptional customer retention (45% reorder rate), suggesting strong after-sales engagement despite slightly lower on-time performance. Xingtai Mintai provides entry-level models starting at $1,550, suitable for small-scale operations but with limited reorder metrics. Qingdao YiDaFa targets high-capacity producers with jumbo roll processing and parallel winding technology, though financial transparency is limited.

FAQs

How to verify paper core making machine supplier reliability?

Cross-check ISO/CE certifications with issuing bodies and request factory audit reports. Review transaction histories focusing on delivery consistency and dispute resolution. Conduct video inspections of production lines to validate claimed capabilities.

What is the typical lead time for standard machines?

Standard models require 20–30 days for production and testing. Customized systems with specialized molds or extended cutting widths may take 35–50 days. Air freight adds 5–7 days; sea shipping ranges from 15–30 days depending on destination port.

Do suppliers support customization of core dimensions and materials?

Yes, most manufacturers allow adjustments to inner diameter (12–300mm), length (up to 3,000mm), and paper layer count. Material compatibility includes kraft, recycled, coated, and laminated papers. Tooling changes for logos or surface textures are typically included in setup fees.

What are common MOQ and pricing structures?

MOQ ranges from 1 unit for semi-automatic models to 5+ sets for fully integrated lines. Prices vary from $1,550 for basic cutters to $24,000 for high-speed automatic winders. Bulk discounts apply beyond three units, with FOB terms standard for international shipments.

Are installation and training services available?

Reputable suppliers provide remote setup guidance via video call and detailed operation manuals. Some offer on-site technician deployment at additional cost. Pre-shipment testing reports and machine calibration certificates should be provided before dispatch.