Manual Soap Making Machine Wholesaler

About manual soap making machine wholesaler

Where to Find Manual Soap Making Machine Wholesalers?

China remains the global epicenter for manual soap making machine manufacturing, with key production clusters concentrated in Henan Province. Zhengzhou, the provincial capital, serves as a primary hub due to its integrated supply chains, skilled labor pool, and advanced logistics infrastructure. Over 70% of listed suppliers for manual soap making equipment operate within this region, benefiting from proximity to steel, casting, and precision machining networks that reduce component lead times by up to 25%.

These industrial ecosystems support vertically aligned production—encompassing mold fabrication, hydraulic system assembly, and finishing operations—within compact geographic zones. This clustering enables wholesalers to maintain lean inventories while fulfilling bulk orders efficiently. Buyers gain access to flexible production models capable of handling both standardized units and customized configurations, with typical lead times ranging from 15 to 30 days for 1–10 set orders. Cost advantages are significant: localized sourcing reduces unit prices by 20–35% compared to equivalent machinery produced in Southeast Asia or Eastern Europe.

How to Choose Manual Soap Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Production Capability

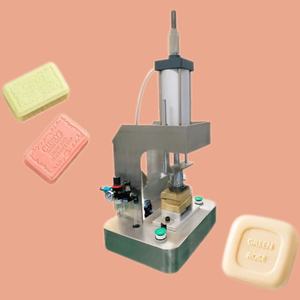

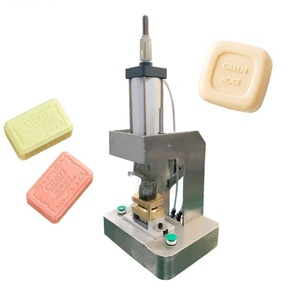

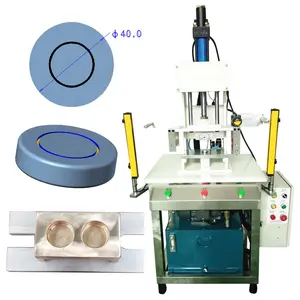

Assess whether suppliers possess in-house engineering and fabrication resources. Key indicators include CNC machining, welding stations, and mold design capabilities. Suppliers offering customization (e.g., logo stamping, variable pressing force, material thickness adjustment) typically maintain dedicated R&D teams. Cross-reference product listings with facility size proxies such as online revenue and order fulfillment metrics.

Quality Assurance Indicators

While formal certifications (ISO 9001, CE) are not universally declared in available data, performance-based metrics serve as reliable proxies:

- On-time delivery rate ≥95%

- Average response time ≤3 hours

- Reorder rate exceeding 15%

- Documented customization options (material, color, branding, automation level)

Suppliers with verified multispecialty status demonstrate compliance with broader quality management expectations through third-party validation systems.

Procurement Risk Mitigation

Prioritize suppliers offering clear pricing structures with transparent minimum order quantities (MOQs). Most manual soap machine wholesalers list MOQs at 1 set, facilitating low-risk sampling. Utilize incremental ordering strategies to validate performance before scaling. Confirm post-purchase support availability, particularly for technical troubleshooting and spare parts supply. Where applicable, request video audits or facility walkthroughs to verify production capacity claims.

What Are the Best Manual Soap Making Machine Wholesalers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Pasen Machinery Co., Ltd. | Zhengzhou, CN | Soap Making Machines, Packaging Equipment | US $250,000+ | 100% | ≤4h | 16% | Color, material, size, logo, packaging, graphic | $360–$6,280 |

| Zhengzhou Fuget Technology Co., Ltd. | Zhengzhou, CN | Soap Machines, Oil Pressers, Filter Presses | US $30,000+ | 100% | ≤2h | <15% | Not specified | $560–$3,100 |

| Henan Lovo Industry Co., Ltd. | Henan, CN | Soap Stamping, Cutting, Bagging Systems | US $540,000+ | 95% | ≤3h | 23% | Multiple parameters including shape, power, labeling, raw material compatibility | $1,099–$26,999 |

| Zhengzhou Share Machinery Co., Ltd. | Zhengzhou, CN | Semi-Automatic Soap Molding, Cold Process Units | US $420,000+ | 100% | ≤3h | <15% | Not specified | $460–$2,999 |

| Lanzhou Xitu Electric Technology Co., Ltd. | Lanzhou, CN | Soap Molding, Labeling, Filling Equipment | US $6,000+ | 100% | ≤1h | <15% | Not specified | $2,540–$13,500 |

Performance Analysis

Zhengzhou Pasen and Henan Lovo stand out for high reorder rates (16% and 23%, respectively) and extensive customization capabilities, indicating strong customer satisfaction and technical flexibility. Henan Lovo’s broad parameter configurability—from soap type to energy consumption profiles—positions it well for niche or branded production. Zhengzhou Fuget and Lanzhou Xitu offer rapid response times (≤2h and ≤1h), enhancing communication efficiency for time-sensitive procurement cycles. Despite lower reported revenue, Lanzhou Xitu maintains competitive pricing on mid-range models and perfect on-time delivery performance. Suppliers like Zhengzhou Share Machinery achieve price consistency across multiple SKUs ($2,999 for several semi-automatic variants), suggesting optimized production lines and economies of scale.

FAQs

What is the typical MOQ for manual soap making machines?

Most wholesalers set a minimum order quantity of 1 set, enabling small-scale buyers and startups to procure equipment without volume commitments. Some listings specify carton-based MOQs (e.g., 2 cartons), which may indicate bundled accessory shipments rather than full machines.

How long does production and shipping take?

Manufacturing lead time for standard units ranges from 10 to 20 days. Customized machines may require 25–35 days depending on complexity. Sea freight from Chinese ports to major global destinations averages 25–40 days, while air express options reduce transit to 5–10 days at higher cost.

Can I customize machine specifications?

Yes, leading suppliers such as Zhengzhou Pasen and Henan Lovo explicitly offer customization for dimensions, materials, logos, and functional components like stamping molds and heating systems. Technical documentation or CAD drawings enhance accuracy in implementation.

Are there quality certifications to look for?

While specific ISO or CE certifications are not detailed in supplier tags, performance metrics such as 100% on-time delivery and multi-year operating histories serve as indirect quality indicators. Buyers requiring certified compliance should request documentation directly during vendor qualification.

What payment and transaction protections are available?

Many suppliers operate under verified trade assurance programs, providing escrow-based payment protection. Transactions are typically secured through milestone payments—deposit upon order confirmation, balance after shipment documentation. For high-value orders, third-party inspection services can be arranged prior to dispatch.