Manual Soap Making Machine Price

About manual soap making machine price

Where to Find Manual Soap Making Machine Suppliers?

China remains the central hub for manual and semi-automated soap making machinery production, with key manufacturing clusters in Henan and Gansu provinces. Zhengzhou, Henan’s capital, hosts a dense network of industrial equipment suppliers specializing in small-scale and artisanal soap processing lines. These suppliers leverage localized supply chains for hydraulic components, stainless steel molds, and pneumatic systems, achieving 20–35% lower unit costs compared to European or North American manufacturers.

The region's vertically integrated production model enables rapid prototyping and scalable output, supporting both low-volume handmade operations and mid-tier commercial producers. Facilities typically operate within compact industrial zones where raw material sourcing, machining, and final assembly occur within a 30-kilometer radius. This proximity reduces lead times to 25–40 days for standard configurations and allows flexibility in MOQ adjustments. Buyers benefit from established export logistics via Zhengzhou’s international freight corridor, ensuring efficient containerized shipping to global markets.

How to Choose Manual Soap Making Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Process Alignment

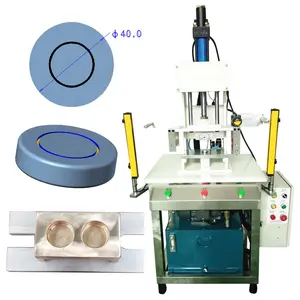

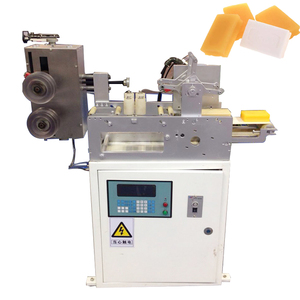

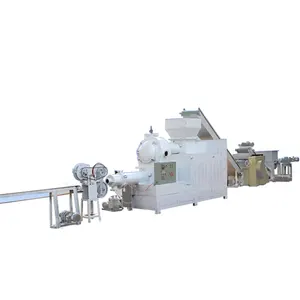

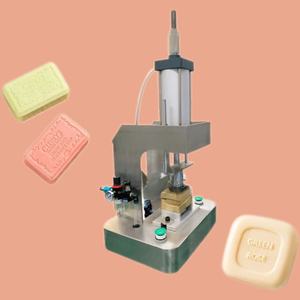

Confirm machine compatibility with intended soap types—cold process, melt-and-pour, or saponification-based formulations. Key parameters include mold cavity size (typically 80–120mm), pressure capacity (≥6 bar for crisp imprinting), and material contact surfaces (food-grade stainless steel 304/316). For manual stamping units, verify ergonomic design and ease of mold replacement. Request detailed CAD drawings and operational schematics prior to order placement.

Production Capability Verification

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area of 1,000m² indicating dedicated production space

- In-house machining capabilities including CNC milling, welding, and surface finishing

- Presence of testing protocols for durability (e.g., ≥10,000 press cycles without deformation)

Cross-reference on-time delivery rates (>97%) and response times (≤4 hours) as indicators of operational reliability.

Quality Assurance & Transaction Security

Prioritize suppliers adhering to ISO 9001 quality management standards. While CE certification is less common among smaller exporters, it should be required for EU market compliance. Utilize secure payment mechanisms such as escrow services, and request sample units to evaluate build quality and functional performance. Conduct video audits of production lines to validate claimed capacities and quality control checkpoints.

What Are the Best Manual Soap Making Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| YUXUN INDUSTRY INC | Zhejiang, CN | Fruit & Vegetable Machines, Oil Pressers | $24,500–29,000 | 1 set | - | ≤4h | - | - |

| Lanzhou Limac Machinery Works Co., Ltd. | Gansu, CN | Soap Making Machines, Wrapping Equipment | $5,000–20,000 | 1 set | - | ≤20h | <15% | US $400+ |

| Zhengzhou Share Machinery Co., Ltd. | Henan, CN | Semi-Automatic Soap Machines, Cutters | $469–2,999 | 1 set | 100% | ≤3h | <15% | US $420,000+ |

| Lanzhou Xitu Electric Technology Co., Ltd. | Gansu, CN | Labeling, Filling, Soap Making Machines | $500–13,000 | 1 piece/set | 100% | ≤1h | <15% | US $6,000+ |

Performance Analysis

Zhengzhou Share Machinery stands out with a high online revenue footprint (US $420,000+) and perfect on-time delivery record, offering cost-effective entry-level machines starting at $469. Lanzhou Xitu demonstrates superior responsiveness (≤1h average reply time) and competitive pricing across semi-automated stamping and pressing units. YUXUN INDUSTRY INC targets premium commercial installations with prices exceeding $24,500, suggesting focus on fully integrated production lines. Lanzhou Limac provides broad configuration options, including complete saponification systems priced from $5,000, suitable for startups and regional producers.

FAQs

What is the typical price range for manual soap making machines?

Prices vary significantly by automation level and output capacity. Entry-level hand-operated stamping and cutting units start at $469, while full manual pressing systems with multiple molds range from $2,600–$3,000. Complete small-scale production lines including mixers, molds, and cutters are priced between $5,000–$20,000.

What are common MOQ and lead time expectations?

Most suppliers list a minimum order quantity of 1 set, facilitating pilot procurement and small business adoption. Lead times typically range from 20–35 days after deposit confirmation, depending on customization complexity. Expedited builds may be available for standard models within 15 days.

Can suppliers customize machine specifications?

Yes, many suppliers offer mold customization (logo imprinting, shape variation), material upgrades (stainless steel thickness), and integration of pneumatic assist systems. Provide technical drawings or physical samples for accurate replication. Custom tooling surcharges typically range from $200–$800.

How to assess machine durability before purchase?

Request test videos demonstrating repeated pressing cycles. Inquire about frame construction (cast iron vs. welded steel), piston seal materials, and wear-resistant coatings. For critical applications, commission a third-party inspection service to conduct on-site functionality and stress tests prior to shipment.

Are spare parts and technical support included?

Support policies vary. Some suppliers include basic spare kits (seals, gaskets) with initial orders. Long-term maintenance depends on supplier engagement—prioritize those offering remote troubleshooting, instructional documentation, and accessible component replacements. Confirm availability of English-language manuals and electrical compatibility (voltage/frequency).