Small Scale Soap Making Machine Price

Top sponsor listing

Top sponsor listing

About small scale soap making machine price

Where to Find Small Scale Soap Making Machine Suppliers?

China remains the global epicenter for small scale soap making machine manufacturing, with key industrial clusters concentrated in Henan and Zhengzhou. These regions host vertically integrated supply chains that support rapid prototyping, cost-efficient production, and scalable output. Suppliers in Zhengzhou dominate the mid-tier machinery segment, leveraging proximity to steel, electrical components, and automation technology suppliers to reduce lead times by 20–30% compared to non-specialized regions.

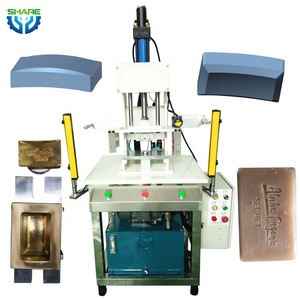

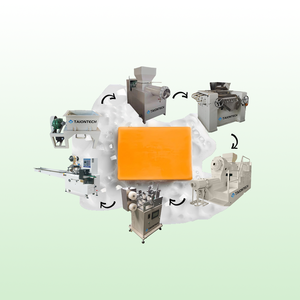

The ecosystem enables streamlined access to modular production lines integrating mixing, extrusion, stamping, cooling, and packaging systems. Localized manufacturing networks allow for flexible configurations tailored to bar soap, laundry soap, or bath soap types, with capacities ranging from 100 kg/day to 500 kg/day. Buyers benefit from consolidated logistics, mature technical labor pools, and established export channels—particularly via Alibaba and other B2B gateways—facilitating direct engagement with verified manufacturers capable of fulfilling international orders.

How to Choose Small Scale Soap Making Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Customization Capability

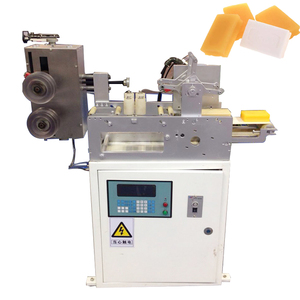

Confirm compatibility with intended soap types (toilet, laundry, medicated) and raw materials (glycerin, tallow, plant-based). Machines should support adjustable parameters including temperature control (via steam or electric heating), mold design flexibility, cutting length precision, and automation level. Evaluate customization options for branding (logo stamping), color coding, packaging integration, and energy consumption optimization. Suppliers offering CAD-based design previews and machine control interface localization (language settings) provide added value for global buyers.

Production Capacity and Quality Assurance

Assess factory infrastructure through available metrics:

- Minimum facility area supporting dedicated assembly lines

- In-house engineering teams enabling process homogenization and troubleshooting

- Integration of preheating, vacuum degassing, and chiller tanks for consistent output quality

- Verification of ISO 9001 compliance or equivalent quality management systems

Cross-reference on-time delivery rates (target ≥96%) and reorder frequency as indicators of reliability and customer satisfaction.

Transaction Security and After-Sales Support

Prioritize suppliers participating in third-party assurance programs. Validate responsiveness (target ≤3 hours) and clarity in communication. Request documentation covering motor specifications (power, voltage), material certifications (stainless steel grade), and safety compliance (CE where applicable). Insist on post-delivery technical guidance, including installation videos, operation manuals, and remote diagnostics availability. Sample testing is recommended to evaluate build quality, noise levels, and continuous operation stability before full-scale procurement.

What Are the Best Small Scale Soap Making Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Zhengzhou Hento Machinery Co., Ltd. | Soap Making Machines, Other Chemical Equipment | 100% | 19% | ≤1h | US $360,000+ | $8,198–$21,833 | Color, size, logo, packaging, material, graphic |

| Zhengzhou Auris Machinery Co., Ltd. | Soap Making Machines, Packaging Equipment | 88% | 15% | ≤2h | US $410,000+ | $4,890–$11,500 | Color, size, logo, packaging, material, graphic |

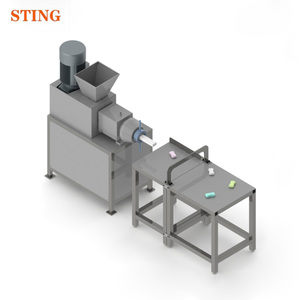

| Nantong Sting Co., Ltd. | Soap Making Machines, Packaging Systems | 100% | 50% | ≤3h | US $320,000+ | $10,000–$80,000 | Full-line integration, plodder extrusion, capacity scaling |

| Zhengzhou Mona Machinery Co., Ltd. | Soap Making Machines, Meat Processing Equipment | 100% | 60% | ≤4h | US $80,000+ | $30/set | Limited (basic line configuration) |

| Henan Lovo Industry Co., Ltd. | Soap Making Machines, Brick Machinery, Conveyors | 96% | 23% | ≤3h | US $540,000+ | Not specified | Extensive: energy consumption, shape, capacity, automation, labeling |

Performance Analysis

Zhengzhou Hento and Nantong Sting demonstrate high delivery reliability (100%) and strong customization depth, positioning them as preferred partners for technically specific requirements. Nantong stands out with a 50% reorder rate, indicating robust customer retention despite higher price points ($10k–$80k), likely due to comprehensive line solutions including plodders and extruders. Zhengzhou Mona offers entry-level pricing at $30/set but appears to focus on compact or component-level units rather than full production lines. Henan Lovo leads in revenue volume (>$540k) and offers broad customization across energy efficiency, output shaping, and automation, making it suitable for diversified manufacturing needs. Auris provides competitive mid-range pricing with solid delivery performance, though its 88% on-time rate warrants closer logistics scrutiny.

FAQs

What is the typical MOQ for small scale soap making machines?

Most suppliers set a minimum order quantity of 1 set, allowing small businesses and startups to procure equipment without bulk commitments. Some offer sample units or partial system trials under special arrangements.

How long does production and shipping take?

Lead time for standard configurations ranges from 15 to 30 days after deposit confirmation. Shipping via sea freight adds 20–40 days depending on destination. Air freight reduces transit time to 5–10 days but increases costs significantly for heavy machinery.

Are CE or ISO certifications common among suppliers?

While not universally declared in product listings, several top-performing suppliers adhere to ISO 9001 standards. Buyers should explicitly request certification documents and verify compliance with local safety and electrical regulations prior to purchase.

Can suppliers integrate labeling, bagging, or wrapping machines?

Yes, leading suppliers such as Henan Lovo and Nantong Sting offer end-to-end integration with bagging machines, label applicators, and conveyor systems. Integration requires advance specification of bag size, material type, and production speed.

Do suppliers provide installation and training support?

Many suppliers include digital resources like instructional videos, user manuals, and troubleshooting guides. Remote video assistance is commonly available. On-site technician deployment may incur additional fees and must be negotiated separately.